Animal Waste Meat Rendering Plant: Case Studies & Custom Solutions

Animal Waste Meat Rendering Plant: Case Studies & Custom Solutions

In the dynamic landscape of agriculture and animal husbandry, the efficient utilization of resources is paramount. Shandong Huimin Feijia Feed Co., Ltd., a subsidiary of Shandong Zhongtian Food Group, has emerged as a trailblazer in the industry by redefining how animal waste is transformed into valuable resources through a state-of-the-art Animal Waste Meat Rendering Plant. With a daily capacity of processing 30 tons of poultry waste, this company has showcased the power of innovation, sustainability, and effective machinery in its operations.

The Animal Waste Meat Rendering Plant stands as a testament to the intersection of waste management, sustainability, and resource utilization. Thanks to innovative manufacturers like SunRise, these facilities are equipped with advanced machine configurations that ensure efficient processing and product extraction. By converting animal by-products into valuable resources like meat and bone meal and refined fats, these plants contribute to both economic and environmental well-being. As the world continues to prioritize sustainable practices, the role of rendering plants in closing the loop on waste disposal becomes increasingly indispensable.

1. The Machinery behind the Transformation: SunRise Rendering Plant

At the heart of Shandong Huimin Feijia Feed Co., Ltd.’s success lies the cutting-edge machinery provided by SunRise, a leading animal poutry waste meat rendering plant machine manufacturer. The partnership between Feijia Feed and SunRise has proven to be a strategic move, enabling the company to achieve remarkable efficiency and productivity gains. SunRise’s rendering plant machinery has played a pivotal role in turning animal poutry waste into high-quality feed ingredients, ensuring minimal wastage and maximum resource utilization.

2. Case Study 1: Enhancing Efficiency and Cost Reduction

One of the standout case studies that exemplify the impact of SunRise’s rendering plant machinery revolves around the enhancement of operational efficiency and cost reduction. By investing in SunRise’s innovative equipment, Shandong Huimin Feijia Feed Co., Ltd. was able to streamline its processes, significantly reducing the time and energy required for animal poutry waste transformation. This efficiency boost not only led to cost savings but also contributed to a more sustainable approach to feed production.

3. Case Study 2: Elevating Product Quality and Customer Satisfaction

Quality is non-negotiable in the livestock industry, and Shandong Huimin Feijia Feed Co., Ltd. recognized this aspect wholeheartedly. Through the adoption of SunRise’s advanced rendering plant machinery, the company was able to ensure the production of high-quality feed ingredients. The technology offered by SunRise facilitated precise temperature and processing control, resulting in feed products with optimal nutritional value and reduced contamination risk. As a result, Feijia Feed witnessed an upsurge in customer satisfaction and loyalty.

4. Sustainability at the Core: A Green Approach

In an era where environmental consciousness is a defining factor, Shandong Huimin Feijia Feed Co., Ltd. has embraced sustainability as a guiding principle. The Animal Waste Meat Rendering Plant Machinery from SunRise aligns seamlessly with this ethos, as it enables the efficient conversion of animal poutry waste into valuable resources, reducing the environmental footprint. The reduction in waste sent to landfills and the production of nutrient-rich feed ingredients further solidify the company’s commitment to a greener future.

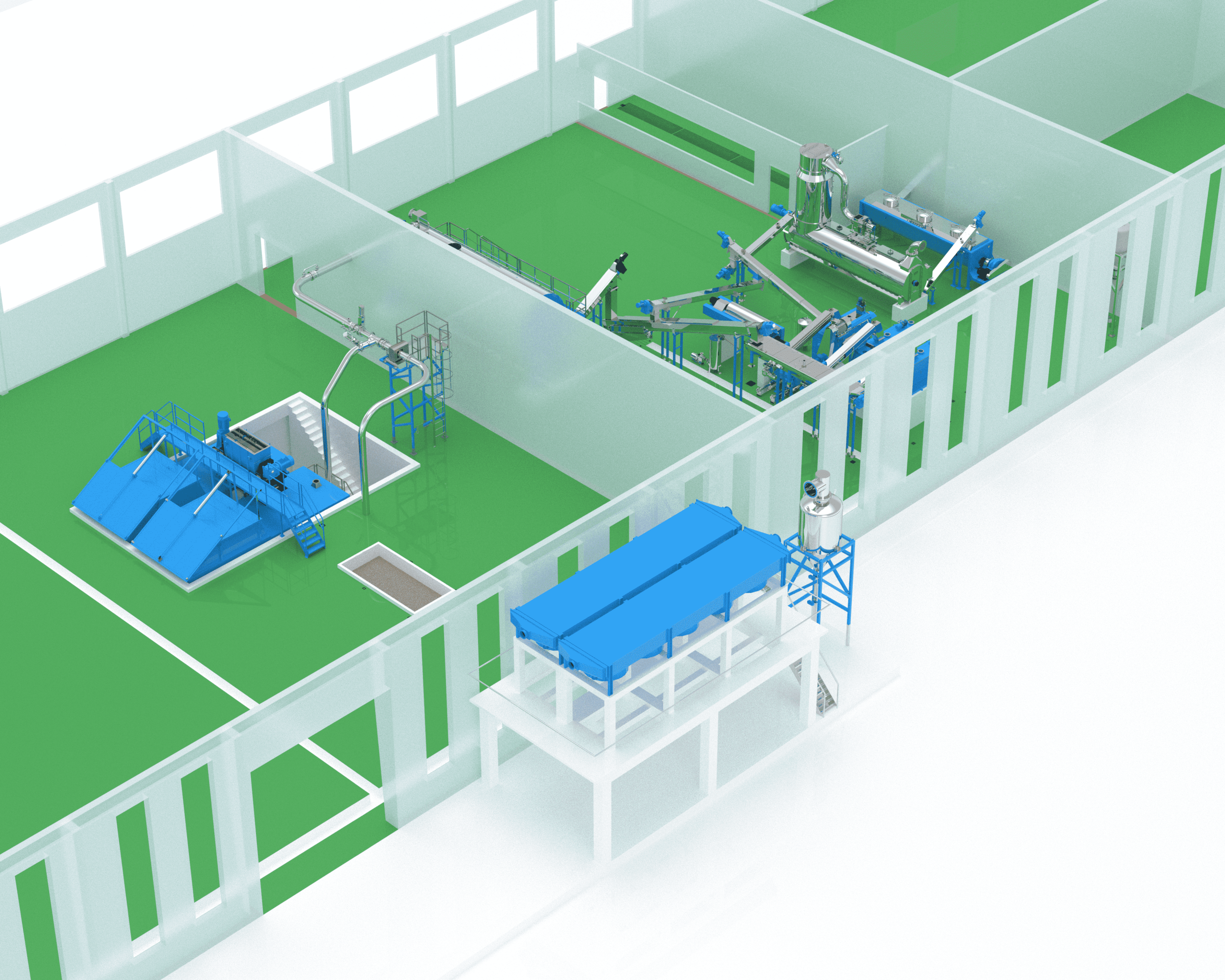

Machine Configuration: The Heart of the Plant

The animal waste meat rendering plant consists of several interconnected machines, each with a specific role in the rendering process. The plant is configured to efficiently handle various types of animal by-products, including bones, fat, feathers, and offal. The machine configuration typically includes:

Cooker: The initial step involves cooking the raw material in a high-pressure steam cooker. This breaks down the tissues and separates the fat from the protein.

Press: The cooked material is then passed through a press to separate the liquid fat (tallow) from the solid protein (meat and bone meal). This step is crucial for both waste reduction and product extraction.

Fat Processing: The collected liquid fat can be further refined and processed into products like tallow, which is used in various industries, including soap production and biofuel.

Processing Plan: From Waste to Resource

The processing plan of an Animal Waste Meat Rendering Plant follows a systematic approach that optimizes waste reduction and product quality. Here’s a breakdown of the steps involved:

1. Collection and Pre-treatment: Animal waste by-products, sourced from slaughterhouses, meat processing plants, and farms, are collected and pre-treated to remove contaminants and foreign matter.

2. Cooking and Sterilization: The pre-treated waste is then introduced into the steam cooker. The high-temperature, high-pressure environment not only breaks down the tissues but also sterilizes the material, eliminating harmful pathogens.

3. Separation of Fat and Protein: The cooked material is pressed to separate the fat-rich liquid from the solid protein. This step is crucial for obtaining both valuable products and reducing the volume of waste.

4. Grinding: The protein-rich solids undergo a drying process to remove moisture, ensuring the longevity of the end products. Subsequently, the dried material is ground into fine particles, creating meat and bone meal.

5. Product Packaging and Distribution: The final products, including meat and bone meal and refined fat products, are packaged and prepared for distribution to industries such as agriculture, animal feed, and biofuel production.

Conclusion: A Bright Future Ahead

Shandong Huimin Feijia Feed Co., Ltd. stands as a shining example of what can be achieved when innovation, sustainable practices, and strategic partnerships converge. With SunRise’s rendering plant machinery as a cornerstone, the company has redefined the utilization of animal waste, elevating feed production standards and contributing to a more environmentally conscious industry. As the journey of Feijia Feed continues, it serves as an inspiration for the entire agriculture and animal husbandry sector to explore and implement groundbreaking solutions that benefit both the industry and the Animal Waste Meat Rendering Plant.

Categories

Recent Posts

-

A guide to Scientists poultry farming on farms: reducing costs, increasing efficiency, and protecting the ecosystem

August 27, 2025 -

Global treatment and sustainable utilization of slaughterhouse waste

August 13, 2025 -

Choosing the right equipment can solve all the problems in animal fat processing

August 1, 2025