To provide you with professional livestock and poultry rendering plant solutions.

ABOUT SUNRISE

Rendering plant processing equipment manufacturer

Sunrise is a comprehensive environmental protection technology limited company dedicated to the feld of animal protein, oil, nutrition,food,bio- technology and solid waste treatment. Our company has introduced and absorbed equipment manufacturing technology, project processing technology and effcient management mode for a century in Europe. Depth development of domestic and foreign markets, and to provide high quality services and provide customers with the perfect solution.

In today’s increasingly competitive market, The challenge for our company must to face is how to maintain our dominance in the market by providing high_quality and price-competitive products.

0

+COMPANY AREA/M²

0

+EMPLOYEES

0

+PATENTS

0

+PROJECTS COMPLETED

Rendering plant processing equipment manufacturer

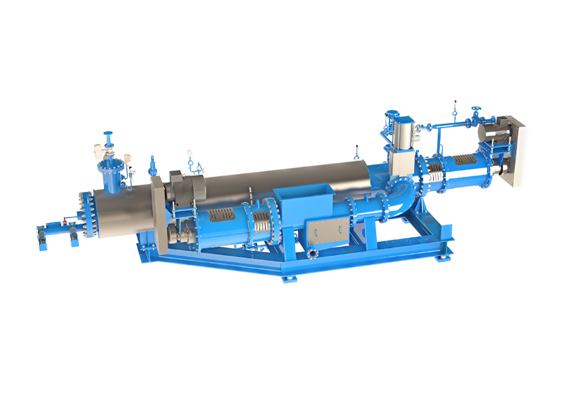

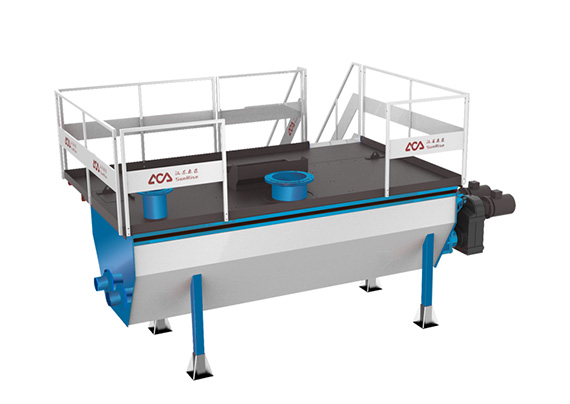

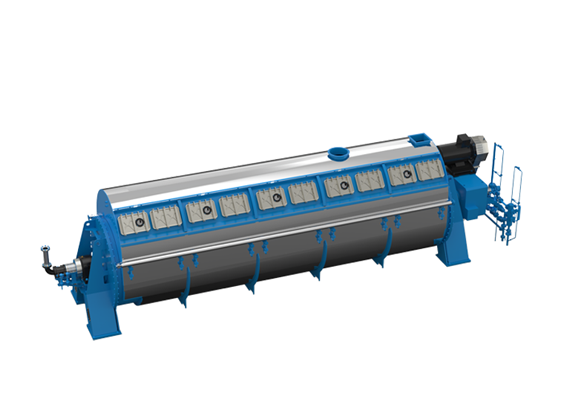

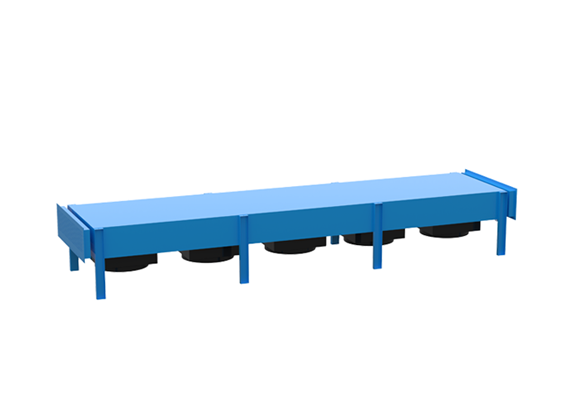

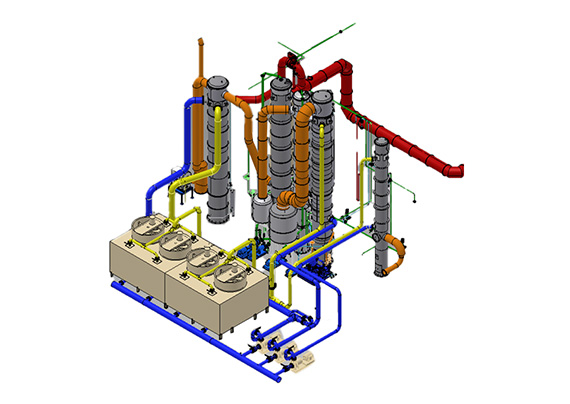

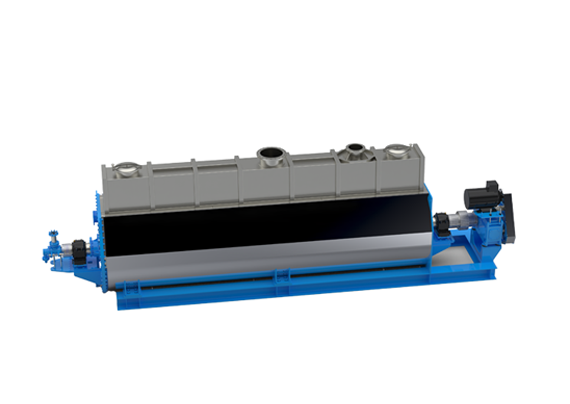

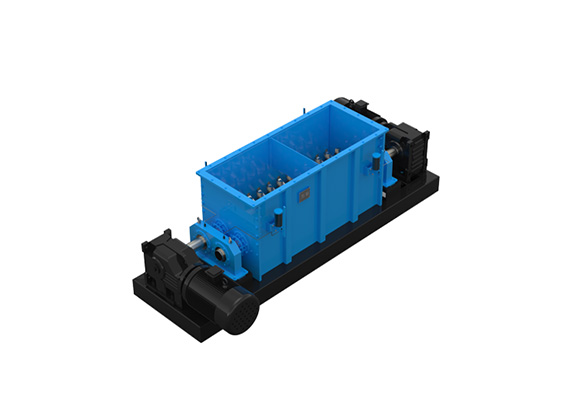

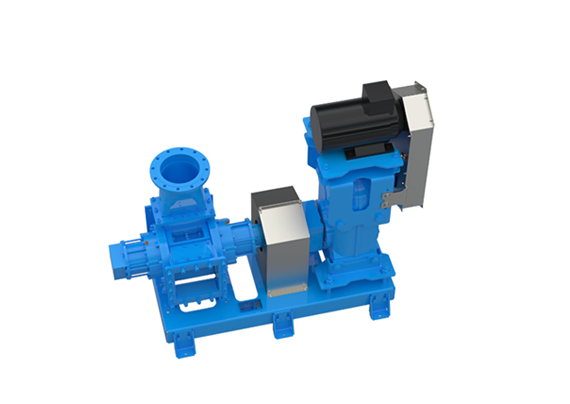

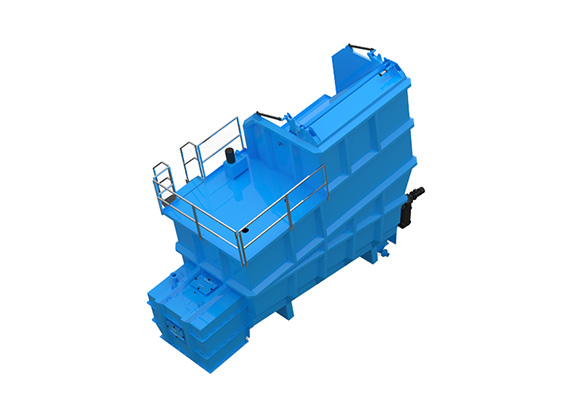

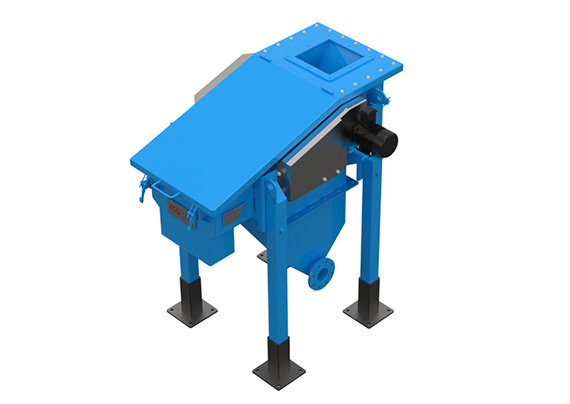

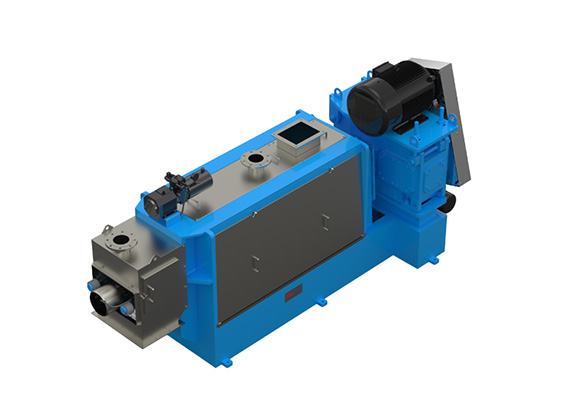

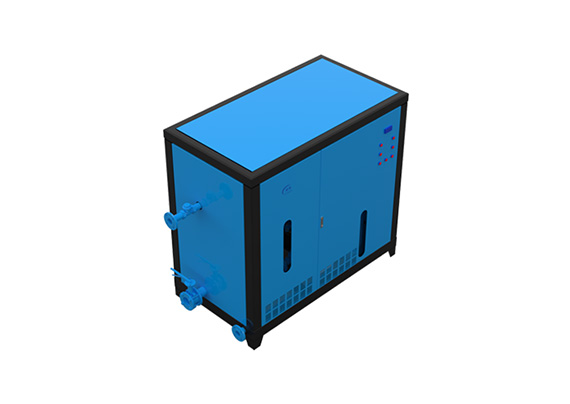

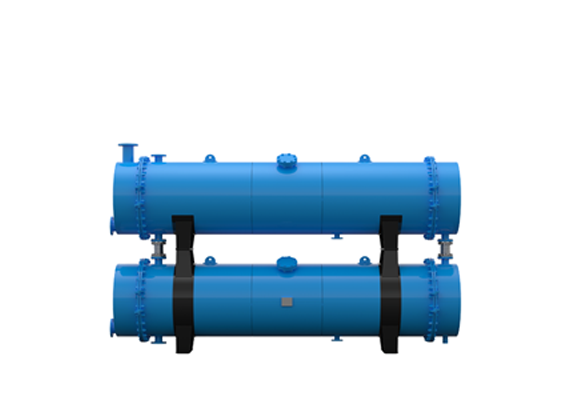

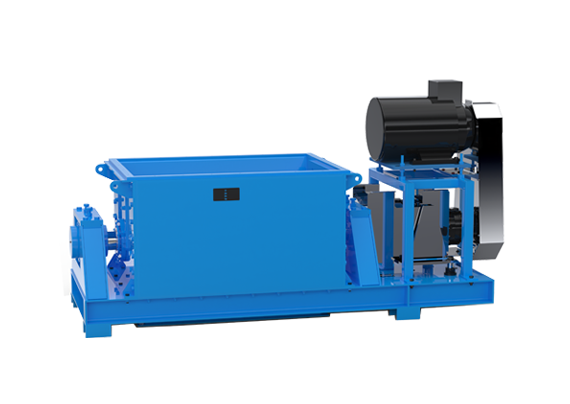

Equipment Display

A comprehensive environmental protection technology company dedicated to the fields of animal protein and nutrition, animal oils and fats, food and biotechnology, kitchen waste treatment, and sludge reduction treatment.

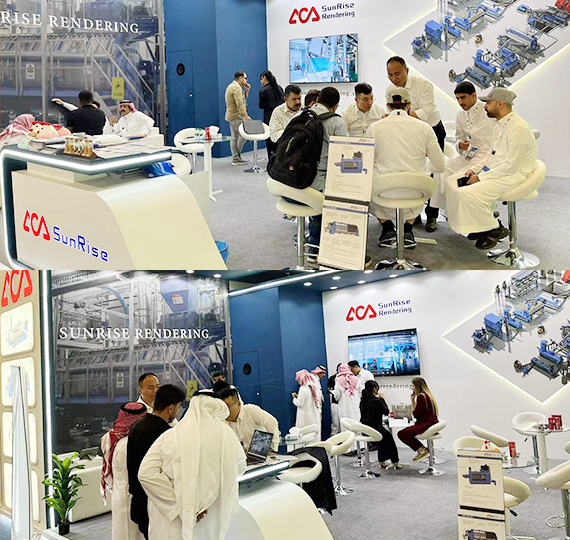

Case Display

Please see our realized projects.

If you need any machine, please contact us by e-mail: sales@cnsenrong.com

TESTIMONIALS

Happy Customers

Sunrise is a modern machinery company with technology research and development, Process Design, Manufacturing, Process teaching and Installation training.