Chemical Scrubber: An Effective Solution for Air Pollution Control

Chemical Scrubber: An Effective Solution for Air Pollution Control

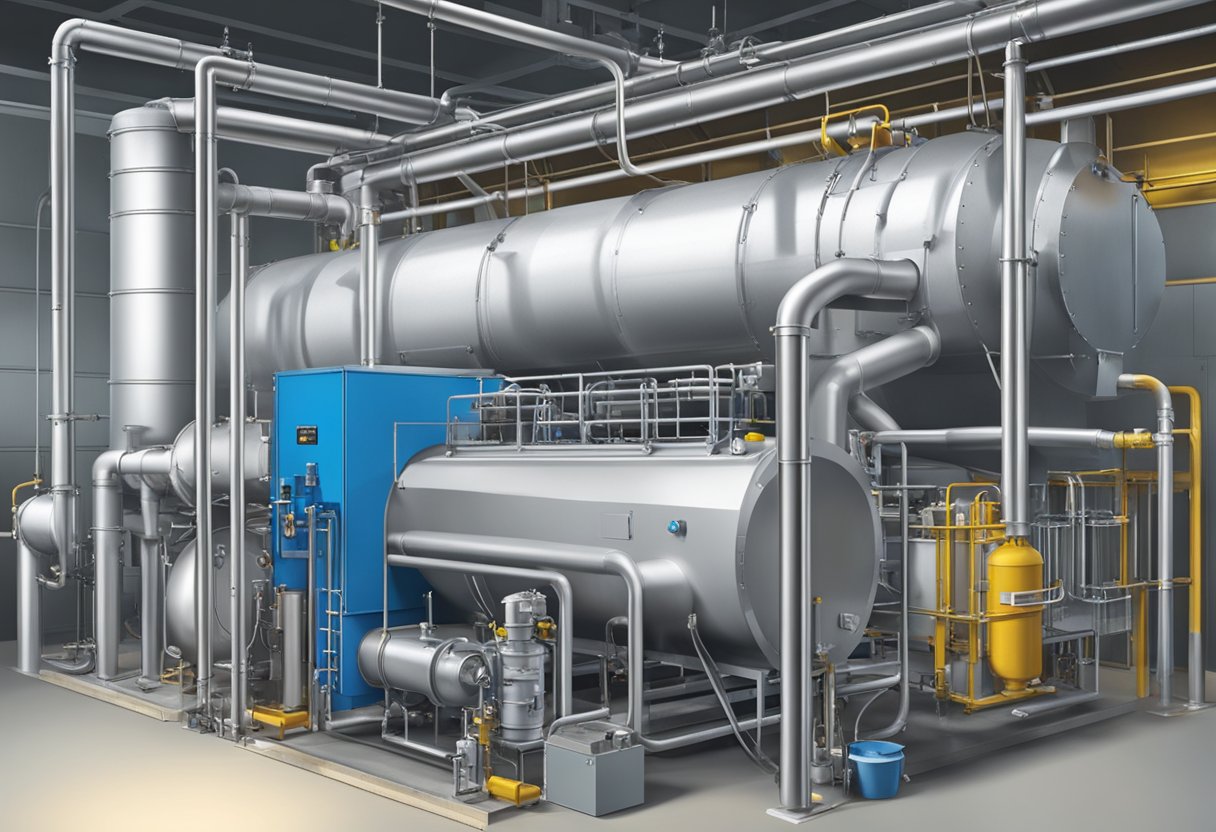

Chemical scrubbers are devices used to remove pollutants and other harmful chemicals from industrial exhaust gases. They are commonly used in a variety of industries, including power plants, chemical manufacturing, and oil refineries. The use of chemical scrubbers has become increasingly important in recent years due to growing environmental concerns and stricter regulations on emissions.

Chemical scrubbers work by passing exhaust gases through a liquid or solid substance, which reacts with and removes the pollutants. The most common types of chemical scrubbers include wet scrubbers, dry scrubbers, and regenerative scrubbers. Wet scrubbers use a liquid to remove pollutants, while dry scrubbers use a solid material such as activated carbon. Regenerative scrubbers are similar to wet scrubbers but are designed to reuse the scrubbing solution, making them more efficient and cost-effective.

Overall, chemical scrubbers are an important tool in reducing the environmental impact of industrial processes. By removing harmful pollutants from exhaust gases, Feather Meal Machine help protect air quality and promote sustainable development. As regulations continue to tighten, the use of chemical scrubbers is likely to become even more widespread in the coming years.

Fundamentals of Chemical Scrubbers

Chemical scrubbers are a type of air pollution control device that are commonly used to remove harmful pollutants from industrial exhaust streams. These scrubbers work by using a chemical reaction to neutralize the pollutants, converting them into less harmful substances before they are released into the atmosphere.

There are several different types of chemical scrubbers, each of which uses a different chemical reaction to remove pollutants. For example, some scrubbers use alkaline solutions to neutralize acidic pollutants, while others use acidic solutions to neutralize alkaline pollutants.

One of the key advantages of chemical scrubbers is their ability to remove a wide range of pollutants, including both particulate and gaseous pollutants. This makes them a versatile solution for many different types of industrial processes.

Chemical scrubbers can also be designed to operate at different temperatures and pressures, depending on the specific application. Some scrubbers are designed to operate at high temperatures, which can be useful for removing pollutants that are released during high-temperature industrial processes.

Overall, chemical scrubbers are an effective and versatile solution for reducing industrial air pollution. By neutralizing harmful pollutants before they are released into the atmosphere, these scrubbers help to protect the environment and improve air quality for everyone.

Design and Engineering

Absorption Tower Design

The absorption tower is the main component of a chemical scrubber system. It is designed to remove pollutants from the gas stream by allowing them to react with a scrubbing solution. The design of the tower is critical to ensure efficient removal of the pollutants.

The tower is typically made of corrosion-resistant materials such as fiberglass or stainless steel. The tower may be packed with materials such as ceramic or plastic to provide a larger surface area for the gas and liquid to interact. The height of the tower is determined based on the desired removal efficiency and the amount of gas to be treated.

Chemical Selection

The selection of the appropriate scrubbing solution is critical to ensure efficient removal of pollutants. The selection of the chemical is based on the type of pollutant to be removed and the operating conditions of the system.

The most commonly used scrubbing solutions include sodium hydroxide, sulfuric acid, and hydrochloric acid. Sodium hydroxide is used to remove acidic gases such as sulfur dioxide and hydrogen chloride. Sulfuric acid is used to remove ammonia and hydrogen sulfide. Hydrochloric acid is used to remove basic gases such as ammonia and amines.

Mass Transfer Considerations

The efficiency of the absorption tower is determined by the mass transfer rate between the gas and liquid phases. The mass transfer rate is affected by the physical properties of the gas and liquid, the surface area available for mass transfer, and the concentration gradient between the gas and liquid phases.

To maximize the mass transfer rate, the gas and liquid flow rates should be optimized based on the properties of the gas and liquid. The use of packing materials such as ceramic or plastic can also increase the surface area available for mass transfer.

In summary, the design and engineering of a chemical scrubber system is critical to ensure efficient removal of pollutants from gas streams. The design of the absorption tower, selection of the appropriate scrubbing solution, and optimization of the mass transfer rate are all important considerations in the design of a chemical scrubber system.

Operational Principles

Chemical scrubbers are used to remove pollutants from gas streams. They use a liquid solution to absorb the pollutants, and then separate them from the gas stream. This section will discuss the operational principles of chemical scrubbers.

Gas Absorption Mechanics

Chemical scrubbers work on the principle of gas absorption. The gas stream is passed through a chamber filled with a liquid solution. The pollutants in the gas are absorbed into the liquid, leaving a clean gas stream. The liquid solution is then separated from the gas stream, and the pollutants are removed from the liquid.

The efficiency of the scrubber depends on several factors, including the type of pollutants in the gas stream, the concentration of pollutants, and the flow rate of the gas stream. The liquid solution used in the scrubber is chosen based on the type of pollutants that need to be removed. It is important to monitor the concentration of pollutants in the gas stream to ensure that the scrubber is working effectively.

pH Control and Monitoring

The pH of the liquid solution is an important factor in the efficiency of the scrubber. The pH affects the solubility of the pollutants in the liquid. The pH of the liquid solution is monitored and controlled to ensure that it remains within the optimal range for the pollutants being removed.

The pH is controlled by adding an acid or a base to the liquid solution. The addition of an acid will lower the pH, while the addition of a base will raise the pH. The pH is monitored using a pH meter, which measures the acidity or alkalinity of the liquid.

In conclusion, chemical scrubbers are an effective way to remove pollutants from gas streams. The gas absorption mechanics and pH control and monitoring are key operational principles that ensure the scrubber is working effectively.

Types of Chemical Scrubbers

Chemical scrubbers are used to remove pollutants from industrial exhaust streams. There are several types of chemical scrubbers, each with its own advantages and limitations. In this section, we will discuss three common types of chemical scrubbers: Packed Bed Scrubbers, Venturi Scrubbers, and Spray Tower Scrubbers.

Packed Bed Scrubbers

Packed bed scrubbers are one of the most common types of chemical scrubbers used in industry. They consist of a tower packed with a bed of inert materials, such as plastic or ceramic, which are wetted with a scrubbing liquid. Polluted gas enters the bottom of the tower and passes through the bed, where it comes into contact with the scrubbing liquid. The pollutants are absorbed into the liquid, which is then collected and treated.

Packed bed scrubbers are effective at removing a wide range of pollutants, including acid gases, particulates, and volatile organic compounds. They are also relatively compact and can be used in a variety of applications. However, they can be expensive to operate and maintain, and may require frequent replacement of the packing materials.

Venturi Scrubbers

Venturi scrubbers use a high-velocity jet of scrubbing liquid to remove pollutants from industrial exhaust streams. The gas stream is forced through a narrow throat, creating a high-velocity jet that entrains the scrubbing liquid. The pollutants are absorbed into the liquid, which is then collected and treated.

Venturi scrubbers are highly efficient at removing particulates and other solids from exhaust streams. They are also relatively compact and can handle high gas flow rates. However, they can be less effective at removing gases and may require a significant amount of energy to operate.

Spray Tower Scrubbers

Spray tower scrubbers use a spray of scrubbing liquid to remove pollutants from industrial exhaust streams. The gas stream is forced through a tower where it comes into contact with the spray, which absorbs the pollutants. The liquid is then collected and treated.

Spray tower scrubbers are effective at removing a wide range of pollutants, including acid gases, particulates, and volatile organic compounds. They are also relatively simple to operate and maintain, and can be used in a variety of applications. However, they can be less efficient than other types of scrubbers and may require a significant amount of liquid to operate.

Applications

Industrial Emission Control

Chemical scrubbers are widely used in industrial emission control processes to remove pollutants from the exhaust gases. These pollutants include sulfur dioxide, nitrogen oxides, and particulate matter. Chemical scrubbers are particularly effective in removing acidic gases from industrial emissions. The scrubbing process involves passing the polluted gas through a liquid solution, usually water, which contains chemicals that react with the pollutants to neutralize them. The neutralized pollutants are then removed from the liquid solution, leaving behind clean air.

Odor Management

Chemical scrubbers are also used for odor management in various industries such as food processing, wastewater treatment, and pulp and paper mills. The scrubbers remove unpleasant odors by capturing and neutralizing the odor-causing compounds. The chemical scrubbers are designed to handle specific odor-causing compounds, and the scrubbing solution is tailored to the specific odor problem.

VOC Abatement

Volatile organic compounds (VOCs) are a significant source of air pollution and are regulated by environmental agencies. Chemical scrubbers are effective in removing VOCs from industrial emissions. The scrubbing solution used in VOC abatement is designed to capture and neutralize the specific VOCs emitted by the industrial process. The scrubbing solution is then treated to remove the captured VOCs, leaving behind clean air.

In summary, chemical scrubbers have various applications in industrial processes, including emission control, odor management, and VOC abatement. These scrubbers are effective in removing pollutants, unpleasant odors, and VOCs from industrial emissions. The specific scrubbing solution used in each application is tailored to the specific pollutants or odors emitted by the industrial process.

Maintenance and Safety

Routine Maintenance Procedures

To ensure the chemical scrubber is operating at optimal efficiency, routine maintenance procedures should be performed periodically. These procedures include checking the pH level of the scrubbing solution, inspecting the scrubber for any signs of corrosion or damage, and replacing any worn or damaged parts.

It is recommended that the pH level of the scrubbing solution be checked at least once a week. The pH level should be maintained between 7 and 9 for optimal performance. If the pH level is too low or too high, the scrubber may not be able to effectively remove pollutants from the air.

Inspecting the scrubber for any signs of corrosion or damage is also important. Corrosion can weaken the structure of the scrubber and cause leaks, while damage to the internal components can reduce the efficiency of the scrubber. Any signs of corrosion or damage should be addressed immediately to prevent further damage.

Replacing worn or damaged parts is also important for maintaining the efficiency of the scrubber. Parts such as the packing material, mist eliminators, and fan blades should be inspected regularly and replaced as needed.

Safety Precautions

Chemical scrubbers can be dangerous if not operated and maintained properly. To ensure the safety of personnel, the following precautions should be taken:

- Always wear appropriate personal protective equipment (PPE) when working with the scrubber. This includes gloves, safety glasses, and respiratory protection.

- Never mix different types of chemicals in the scrubber. This can cause a dangerous reaction and release toxic gases.

- Always follow the manufacturer’s instructions for operating and maintaining the scrubber.

- Ensure that the scrubber is properly grounded to prevent electrical hazards.

- Never attempt to repair or modify the scrubber without proper training and authorization.

By following these routine maintenance procedures and safety precautions, the chemical scrubber can operate safely and efficiently for years to come.

Performance Metrics

Efficiency Evaluation

The performance of chemical scrubbers is evaluated based on their ability to remove pollutants from the exhaust gas stream. The efficiency of the scrubber is measured in terms of the removal efficiency of the target pollutant(s). The removal efficiency is expressed as a percentage of the inlet concentration of the pollutant(s).

The efficiency of a chemical scrubber depends on several factors such as the type of pollutant, the inlet concentration of the pollutant, the type of scrubbing liquid used, the contact time between the gas and the liquid, and the design of the scrubber.

To evaluate the efficiency of a chemical scrubber, a performance test is conducted in which the inlet and outlet concentrations of the pollutant(s) are measured. The removal efficiency of the scrubber is then calculated using the following formula:

Removal Efficiency (%) = (Inlet Concentration – Outlet Concentration) / Inlet Concentration x 100

Emission Standards Compliance

Chemical scrubbers are designed to comply with various emission standards set by regulatory agencies. The emission standards specify the maximum allowable concentration of pollutants in the exhaust gas stream.

To ensure compliance with the emission standards, the performance of the chemical scrubber is monitored regularly. The inlet and outlet concentrations of the pollutants are measured, and the removal efficiency of the scrubber is calculated. If the removal efficiency is below the required level, corrective action is taken to improve the performance of the scrubber.

Chemical scrubbers are an effective technology for controlling air pollution. They are widely used in various industries to remove pollutants from the exhaust gas stream. The performance metrics discussed in this section provide a basis for evaluating the efficiency and compliance of chemical scrubbers.

Environmental Impact

Waste Handling and Disposal

Chemical scrubbers are an effective way to remove harmful pollutants from industrial exhaust gases. However, they produce waste that must be handled and disposed of properly. The waste generated from chemical scrubbers contains high levels of contaminants, making it hazardous to the environment if not disposed of properly.

The waste can be disposed of in a variety of ways, such as landfill disposal, incineration, or recycling. Landfill disposal is the most common method of disposal, but it can have negative impacts on the environment. Incineration is another option, but it can release harmful pollutants into the air. Recycling the waste is the most environmentally friendly option, but it can be expensive and difficult to implement.

Regulatory Compliance

Chemical scrubbers are subject to numerous environmental regulations, including the Clean Air Act and the Resource Conservation and Recovery Act. These regulations require companies to monitor and report their emissions, as well as properly handle and dispose of their waste.

Failure to comply with these regulations can result in fines and legal action. It is important for companies to stay up-to-date on the latest regulations and ensure that they are in compliance to avoid potential legal and financial consequences.

Overall, while chemical scrubbers are effective at reducing harmful pollutants, they do produce waste that must be handled and disposed of properly to avoid negative impacts on the environment. Companies using chemical scrubbers must also comply with environmental regulations to avoid legal and financial consequences.

Technological Advancements

Innovations in Scrubber Design

Chemical scrubbers have undergone significant technological advancements in recent years. One of the most notable improvements has been in the design of scrubber systems. Modern scrubber systems are designed to be more efficient, reliable, and cost-effective than their predecessors.

New scrubber designs incorporate features such as multiple stages, variable flow rates, and automated controls. These features allow scrubbers to operate more efficiently and effectively, reducing the amount of energy and resources required to achieve the desired level of air pollution control.

Advances in Absorbent Materials

Another area of significant advancement in chemical scrubber technology has been in the development of new absorbent materials. Absorbent materials are a critical component of scrubber systems, as they are responsible for removing pollutants from the air.

Recent advancements in absorbent materials have focused on improving their performance, durability, and cost-effectiveness. New materials have been developed that are more effective at removing pollutants, have a longer lifespan, and are less expensive to manufacture.

Some of the most promising absorbent materials include activated carbon, zeolites, and metal oxides. These materials have been shown to be highly effective at removing a wide range of pollutants from the air, including volatile organic compounds (VOCs), sulfur dioxide (SO2), and nitrogen oxides (NOx).

Overall, these technological advancements have made chemical scrubbers an increasingly viable option for companies looking to reduce their environmental impact and comply with air pollution regulations. With continued research and development, it is likely that scrubber systems will become even more efficient and effective in the years to come.

Market Trends and Future Outlook

Chemical scrubbers are becoming increasingly popular in various industries due to their ability to remove harmful pollutants from the air. The global market for chemical scrubbers is expected to grow at a steady rate in the coming years, driven by increasing environmental regulations and growing awareness of the importance of clean air.

One of the major trends in the chemical scrubber market is the shift towards more sustainable and energy-efficient systems. Manufacturers are focusing on developing scrubbers that consume less energy and produce fewer emissions, making them more environmentally friendly and cost-effective for businesses.

Another trend is the adoption of advanced technologies such as artificial intelligence and machine learning in chemical scrubbers. These technologies enable scrubbers to operate more efficiently and effectively, improving their performance and reducing maintenance costs.

The future outlook for the chemical scrubber market looks promising, with continued growth expected in the coming years. As more countries implement stricter environmental regulations, the demand for chemical scrubbers is likely to increase, particularly in industries such as power generation, chemical manufacturing, and oil and gas.

Overall, the chemical scrubber market is poised for steady growth in the coming years, driven by increasing demand for clean air and sustainable technologies. As manufacturers continue to innovate and improve their products, the use of chemical scrubbers is likely to become even more widespread across various industries.