Description

Exhaust Abatement Product use

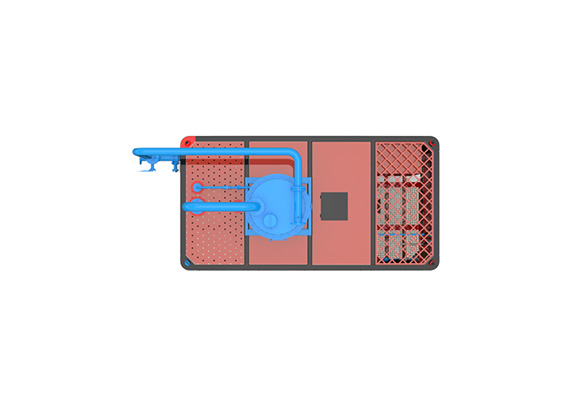

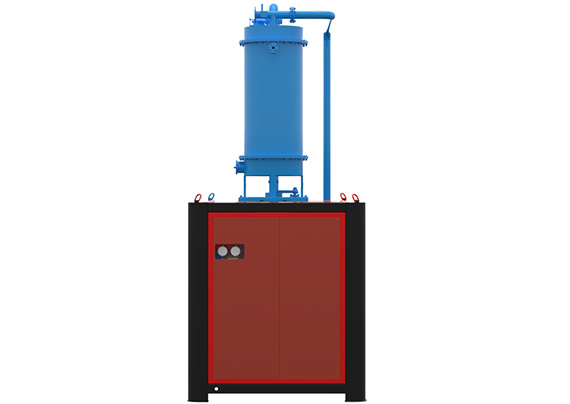

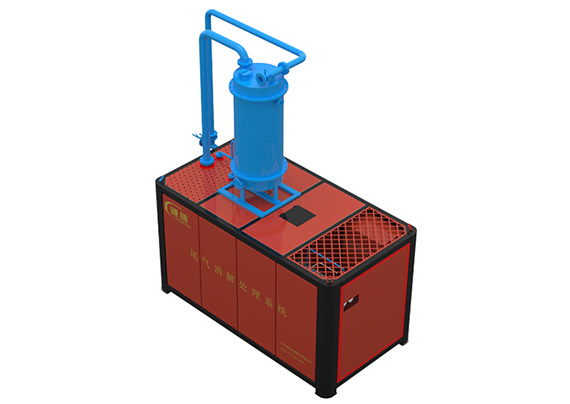

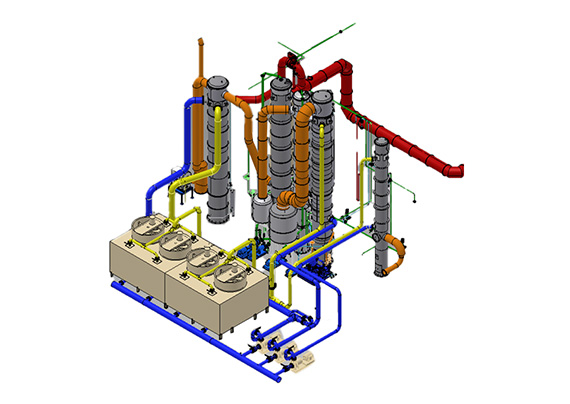

The Exhaust Abatement product is mainly suitable for livestock and poultry harmless treatment, slaughtering waste protein conversion of feather meal, meat meal, animal fat melting, and other conditions, the odor gas extracted under the condition of negative pressure vacuum catalytic combustion purification treatment.

Main features of the product

1. Adopt the heat storage catalytic combustion process to fully burn the substances in the odor gas, and the exhaust gas after combustion enters the spray tower for absorption, and finally discharged with standards.

2. The porous refractory heat storage body in the combustion furnace is loaded with a special catalyst. The catalyst adsorbed and deposited in the heat storage body with stable chemical characteristics. At the same time, the catalyst can maintain good recycling characteristics at high temperatures, and the service life matches the whole cycle life of the equipment.

3. The combustion system realizes multiple interlock and has automatic distribution system for monitoring gas pressure, wind pressure and flame temperature, which has safety and industrial reliability.

4. The equipment is easy to operate, using LNG as fuel. The average hourly consumption of LNG is about 5m³, and the maximum processing capacity of odor gas is 500m³. Low operating cost.

Working principle

A large amount of malodorous gas will be generated during the production process of harmless treatment of sick and dead livestock and poultry, protein transformation of slaughterhouse waste (feather meal, meat meal, etc.), animal fat smelting, etc., including hydrogen sulfide, methyl mercaptan, amine (ammonia, pentane diamine) and other malodorous organic substances.

The odorous gas enters the combustion furnace through the air inlet pipe. Under the condition of excessive oxygen, the combustion system uses the catalytic combustion process to fully oxidize, crack and burn the organics in an environment of about 750 ℃, and the odorous organics are converted into substances that are easy to be absorbed (carbon dioxide, water and nitrogen or nitrogen oxides, etc.). The tail gas after combustion finally enters the spray tower for absorption, and finally reaches the discharge standard.

What is Exhaust Abatement

They refer to the measures taken to reduce or eliminate harmful pollutants from vehicle exhaust emissions. This can include technologies such as catalytic converters, diesel particulate filters, and selective catalytic reduction systems. The objective is to decrease the quantity of detrimental pollutants discharged into the atmosphere and enhance the quality of the air.

Exhaust Abatement FQA

Q: What are the pollutants typically targeted by exhaust abatement technologies?

A: Common pollutants targeted include carbon monoxide (CO), nitrogen oxides (NOx), particulate matter (PM), and hydrocarbons (HC).

Q: What are some examples of exhaust abatement technologies?

A: Instances of exhaust abatement technologies encompass catalytic converters, diesel particulate filters, selective catalytic reduction systems, and oxidation catalysts.

Q: How does exhaust abatement impact the environment and public health?

A: Exhaust abatement technologies aid in decreasing the emission of harmful pollutants into the atmosphere, resulting in enhanced air quality and mitigated public health risks linked to exposure to these substances.

Q: Are exhaust abatement technologies mandatory for all vehicles?

A: Exhaust abatement technology prerequisites differ based on jurisdiction; however, in numerous instances, they are obligatory for specific vehicle categories (such as heavy-duty diesel vehicles) or in regions characterized by elevated air pollution levels.