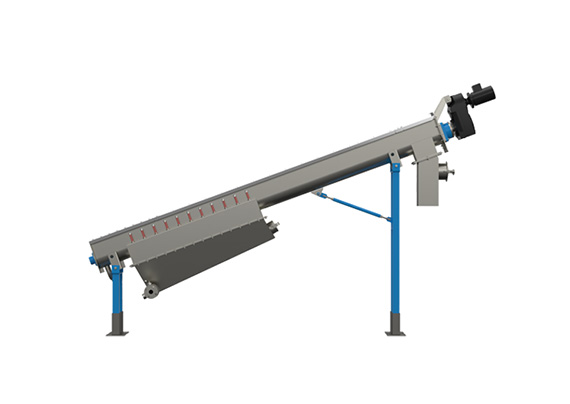

Screw Conveyor / Conveyor Screw

- Brand: Sunrise

- Application: Feather Meal Project | Fish Meal Plant | Meal Plant & Fat Plant | Rendering Plant

- Shipping: Air / Sea / Train / Truck

- Warranty Period: One Years with Lifelong Free Service

- Alias: conveyor screw / Rosca transportadora / Rosca transportadoras / Screw conveyor manufacturers / screw conveyor for sale / screw conveyor price / screw auger conveyor for sale / screw conveyors / small screw conveyor / screw conveyor dryer

Description

Application

Screw conveyor is specially designed for material transportation. Used for: slaughtering, pet food, fish meal.

screw conveyor manufacturers near me SunRise

- Food Handling: Screw conveyors find application in transporting food items like grains, flour, sugar, and spices, facilitating their movement across different processing phases.

- Farming: They are employed for transporting agricultural goods like grain, feed, and fertilizer within processing and storage facilities.

- Medicinal Industry: Screw conveyors play a pivotal role in transferring powders, granules, and other substances throughout the production stages of pharmaceutical goods.

- Mining: They are used to move ore, coal, and other mining products through processing and storage facilities.

- Construction: Screw conveyors are used to move cement, sand, gravel, and other construction materials.

- Power Generation: They are used to move coal, ash, and other materials in power generation facilities.

- Pulp and Paper: Screw conveyors are used to move wood chips, pulp, and other materials in pulp and paper mills.

- Chemical Processing: Screw conveyors are used to move chemical products, such as acids, alkalis, and solvents, through processing facilities.

- Waste Management: Screw conveyors are used to move waste materials, such as sewage, through treatment facilities.

- Recycling: They are used to move recyclable materials, such as paper, plastic, and metal, through recycling facilities

What is a Screw Conveyor

A screw conveyor is a type of mechanical conveyor that uses a rotating helical screw blade, called a “flighting,” within a tube or trough, to move bulk materials horizontally or at an incline. It is a prevalent choice for transferring materials ranging from powders, granules, and small fragments to liquids and sludges across diverse sectors, including agriculture, mining, food processing, and waste management.Screw conveyors exhibit adaptability, functioning effectively in both horizontal and vertical setups, and can be propelled by either an electric motor or a diesel engine.Their design is characterized by its simplicity and efficiency, allowing for straightforward disassembly to facilitate cleaning or maintenance procedures.

Design characteristics and options

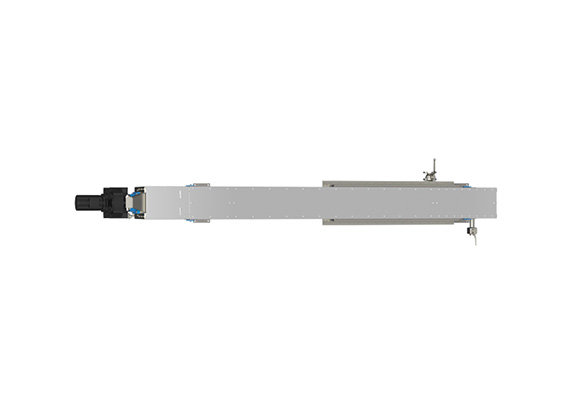

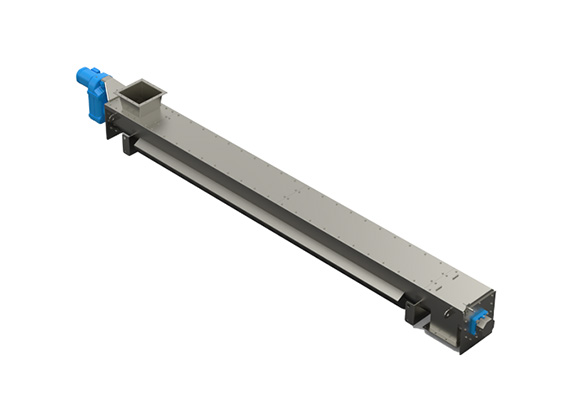

(1)Standard screw conveyor

1. U shape screw conveyor is designed instainless steel material, increase the corrosion resistance of equipment.

2. Between screw shaft, we use alloy steel pipe and spiral blade welding, select screw blade with standard diameter, screw pitch , to guarantee material delivery stability.

3. The design for low-carbon steel wear plate avoid the direct friction between blade and body, increase the service life of the equipment.

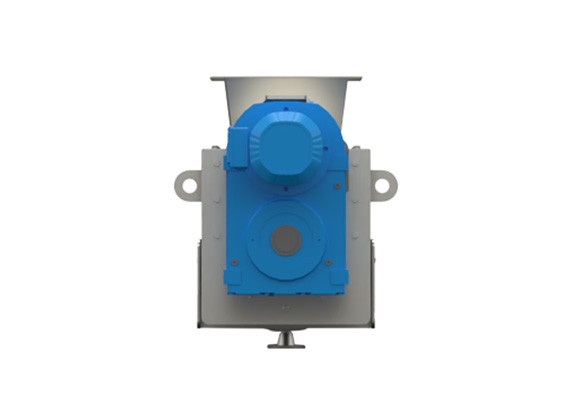

4. Independent drive and design from leading part let the overhaul more convenient.

5. Cover is designed withstainless steel, sealed with body, create a closed workspace, prevent colour leakage.

6. Leg is designed withstainless steel.

7. Stand material is carbon steel with galvanized or colour painted.

8. Covermaterial is stainless steel.

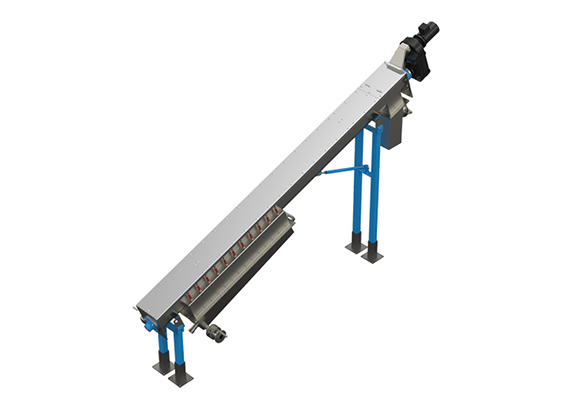

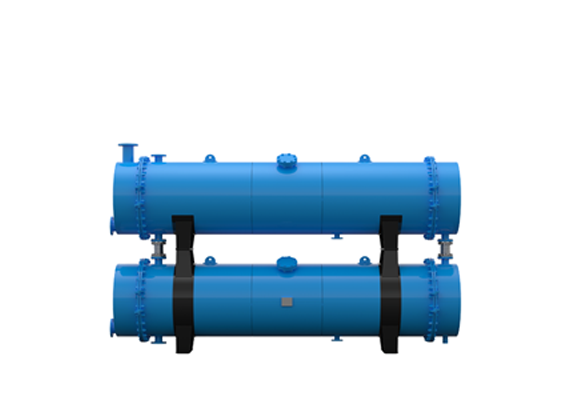

(2) Pre-heating (or water cooled) screw conveyor

1. Increased jacket and one set pipe valve at bottom of U shape groove

2. When the internal medium of system jacket is saturated steam, screw conveyor preheat the material in transportation as

3. Preheating screw conveyor.

4. When the internal medium of system jacket is cooled water, screw conveyor cool the material in transportation as water cooled screw conveyor.

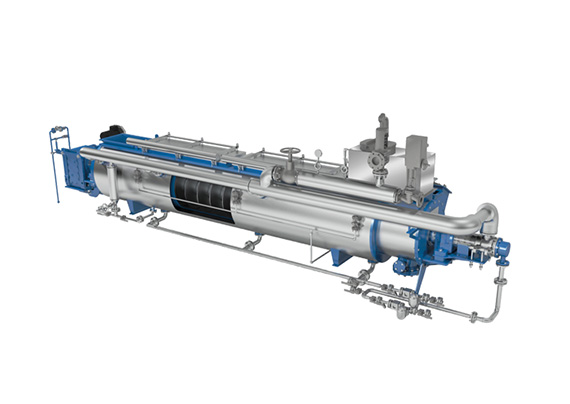

(3) Drain screw conveyor

1. Design the strainer at the bottom of U groove, the diameter of drainer is adjusted according to the material.

2. The design of drainer will make pre-extrusion and collect the liquid or fat in transportation of material, so improve the oil pressing efficiency.

(4) Air cooled screw conveyor

1. At the top of screw, we designed air cooled system, material is cooled by air in transportation.

2. Used for cooling less material, cooling capacity is calculated according to the material throughput.

Technical parameters

| Model | Screw Diameter | Material | Motor/gear brand | Bearing Brand | Basic Parameter | |||||

| Body | Screw | A | B | C | D | Shipping Weight | ||||

| XXX-XX-XXXX | Ø300/400/500/600 | Stainless steel | Carbon steel | As customer requirement | As customer requirement | According to the model which customer choose. | ||||

Screw Conveyor FQA

Screw conveyors are a type of mechanical conveyor that use a rotating helical screw blade, also known as a “flighting,” to move liquid or granular materials. They are commonly used in industrial settings for the transportation of bulk materials such as powders, grains, and small parts. Here are some frequently asked questions about screw conveyors:

1.How does work?

It works by rotating a helical screw blade, or flighting, inside a tube or trough. As the screw rotates, it pushes material forward, moving it along the conveyor.

2.What materials can be transported ?

Screw conveyors possess the capability to transfer a diverse range of materials, encompassing powders, granules, crystals, pellets, and small components. They find frequent application across industries such as food, agriculture, pharmaceuticals, and mining.

3.What are the advantages of using a screw conveyor?

They exhibit simplicity, efficiency, and versatility. They excel in transporting materials both horizontally and on inclines, offering easy adaptability to various scenarios. Furthermore, they are economically viable and demand minimal maintenance.

4.What are the disadvantages ?

Screw conveyors are not suitable for materials that are easily compacted or have a tendency to “bridging”, also it’s not suitable for material with high moisture content, high temperature, and corrosive materials.

5.How can I determine the right size ?

Sizing a screw conveyor depends on factors like the conveyed material, desired conveyance speed, and required capacity.