Description

Application

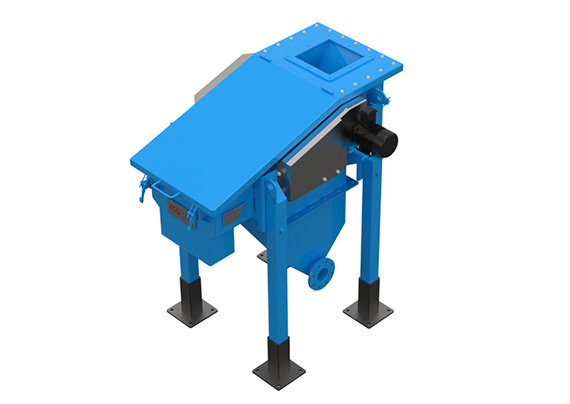

The vacuum pump unit compresses the air, and the pump extracts the condensed water to achieve the purpose of material drying and wastewater collection. Vacuum pump units find application across a diverse range of uses, including:

- Industrial processes such as vacuum drying, degassing, and distillation

- Medical equipment such as vacuum-assisted delivery devices

- Laboratory equipment for vacuum filtration, distillation, and freeze-drying

- HVAC systems for building ventilation and air conditioning

- Automotive engines for improving fuel efficiency and emissions control

- Research and development in physics, chemistry, and materials science

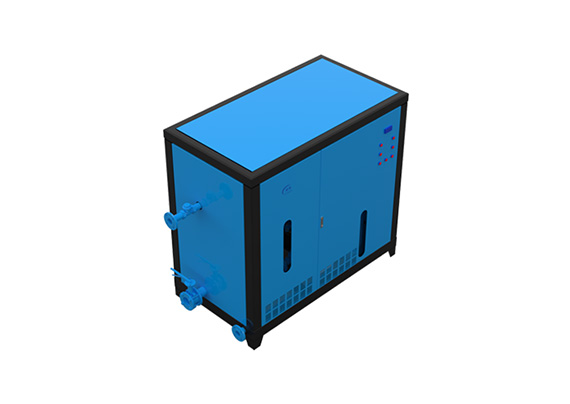

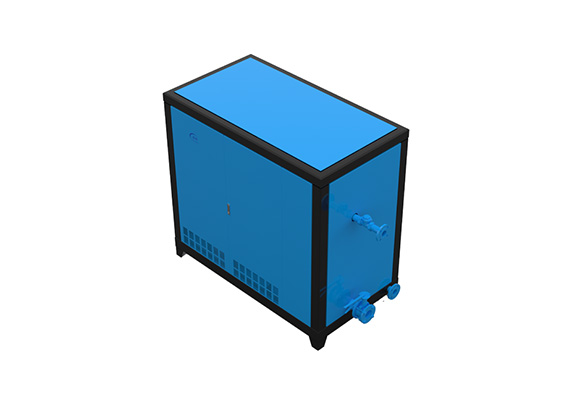

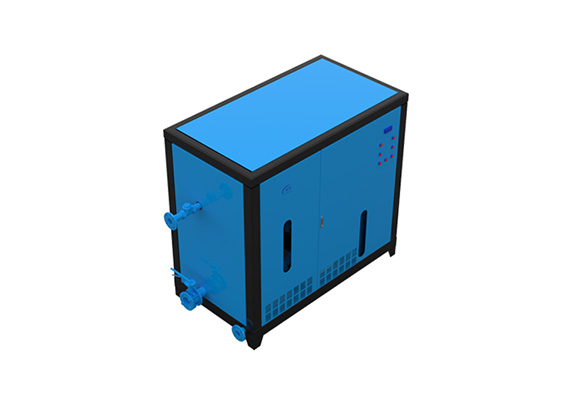

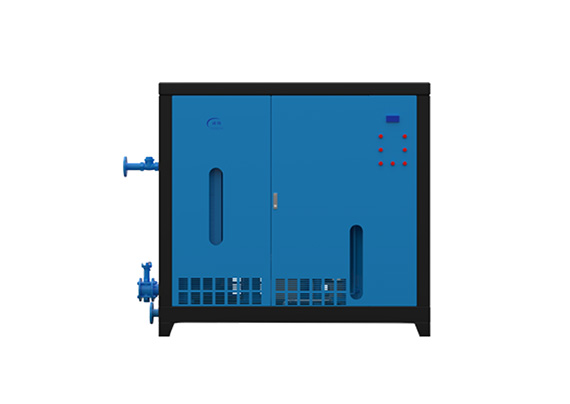

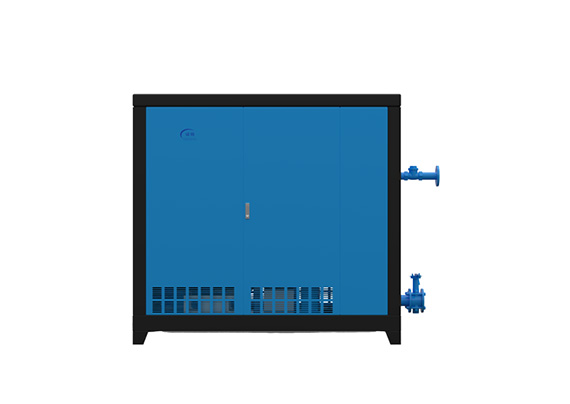

what is Vacuum Pump Unit

A vacuum pump unit is a tool employed to generate and uphold a vacuum. Normally, it comprises of a pump – such as rotary vane, diaphragm, or turbo pump – coupled with a set of valves and gauges. These components work collectively to manage the vacuum level and assess the pump’s efficiency. Vacuum pump units find utilization across an extensive array of contexts, encompassing laboratory research, industrial operations, and medical procedures.

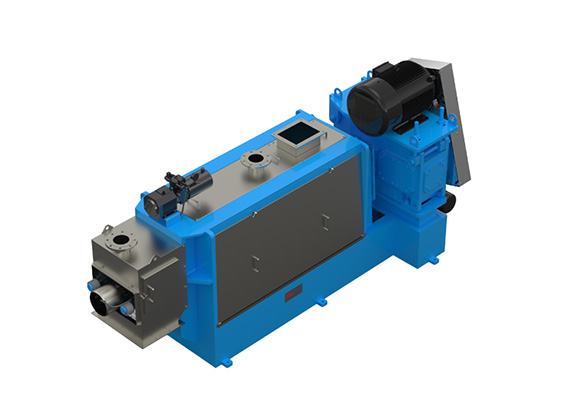

Technical parameter

| Name | Model | Power |

| Vacuum Pump Unit | CZBZ-0.4-1 | 7.7 |

Vacuum Pump Unit FQA

A vacuum pump unit is a tool designed to eliminate air and other gases from a sealed enclosure or system, ultimately generating a vacuum within it. Here are some frequently asked questions and answers about It:

Q: How does work?

A: It works by creating a suction that removes air and other gases from a sealed container or system. The suction originates from a motor that propels a mechanical or electrical apparatus, such as a piston, rotor, or diaphragm. This device generates a region of reduced pressure within the enclosed space or system.

Q: What are the different types?

A: Diverse kinds of vacuum pump units exist, encompassing mechanical pumps like reciprocating and rotary vane pumps, electrical pumps such as diaphragm and turbo pumps, and hybrid pumps that amalgamate the attributes of mechanical and electrical pumps.

Q: What are some common uses?

A: It finds application across a broad spectrum of industries and contexts, spanning manufacturing, research, and medical instrumentation. Some common uses include degassing liquids, removing air from sealed containers, and creating a vacuum for specific industrial processes.

Q: What are the factors that affect the performance o?

A: Elements influencing the efficacy of a vacuum pump unit encompass the unit’s dimensions and configuration, the pump type employed, the characteristics of the fluid or gas being evacuated, as well as the prevailing operational conditions like temperature and pressure.

Q: How do you maintain a vacuum pump unit?

A: Preserving a vacuum pump unit necessitates adhering to the maintenance timetable prescribed by the manufacturer and ensuring the unit remains unsoiled and devoid of any debris. The unit may also require regular oil changes, filter replacements, and other routine maintenance to keep it running efficiently.