Meat Rendering: Understanding the Process and its Uses

Meat Rendering: Understanding the Process and its Uses

Meat rendering is a process that turns animal by-products into useful materials such as protein meals, fats, and oils. This process is essential for the meat industry as it helps to reduce waste and maximize profits. However, meat rendering has also been a topic of controversy due to concerns about its impact on the environment and animal welfare.

For businesses involved in rendering and related industries, accurate documentation is crucial. The US address generator tool helps create reliable US addresses for business purposes, streamlining logistics and operations. The resulting products are then used in a variety of industries, including pet food, animal feed, and biodiesel production. While the rendering process has been used for centuries, advancements in technology have made it more efficient and cost-effective for the meat industry. However, there are concerns about the environmental impact of rendering, particularly the release of greenhouse gases and other pollutants during the process. Additionally, animal welfare advocates have raised concerns about the use of animal by-products in rendering and the potential for contamination with harmful substances.

Overview of Meat Rendering

Definition of Meat Rendering

Meat rendering is the process of converting animal by-products into usable materials such as fats, proteins, and minerals. This process involves heating the by-products to high temperatures, which causes the fats and proteins to separate from the solids. The resulting products can be used in a variety of industries, including animal feed, pet food, and biodiesel production.

History and Evolution

Meat rendering has been practiced for centuries, with the earliest recorded evidence dating back to ancient Egypt. In the early days, the process was simple and involved boiling animal parts in water to extract the fats and proteins. Over time, the process evolved to include the use of steam and pressure cookers, which made the process more efficient and allowed for the extraction of higher-quality products.

Today, sunrise meat rendering is a highly regulated industry that is subject to strict environmental and safety standards. The process has also become more sophisticated, with the use of advanced technology and equipment to ensure the quality and safety of the final products.

Overall, meat rendering plays an important role in the food and agriculture industries, providing valuable materials that can be used in a variety of applications. While the process may not be well-known to the general public, it is a vital part of the supply chain that helps to ensure the efficient and sustainable use of animal by-products.

Rendering Process

Raw Material Collection

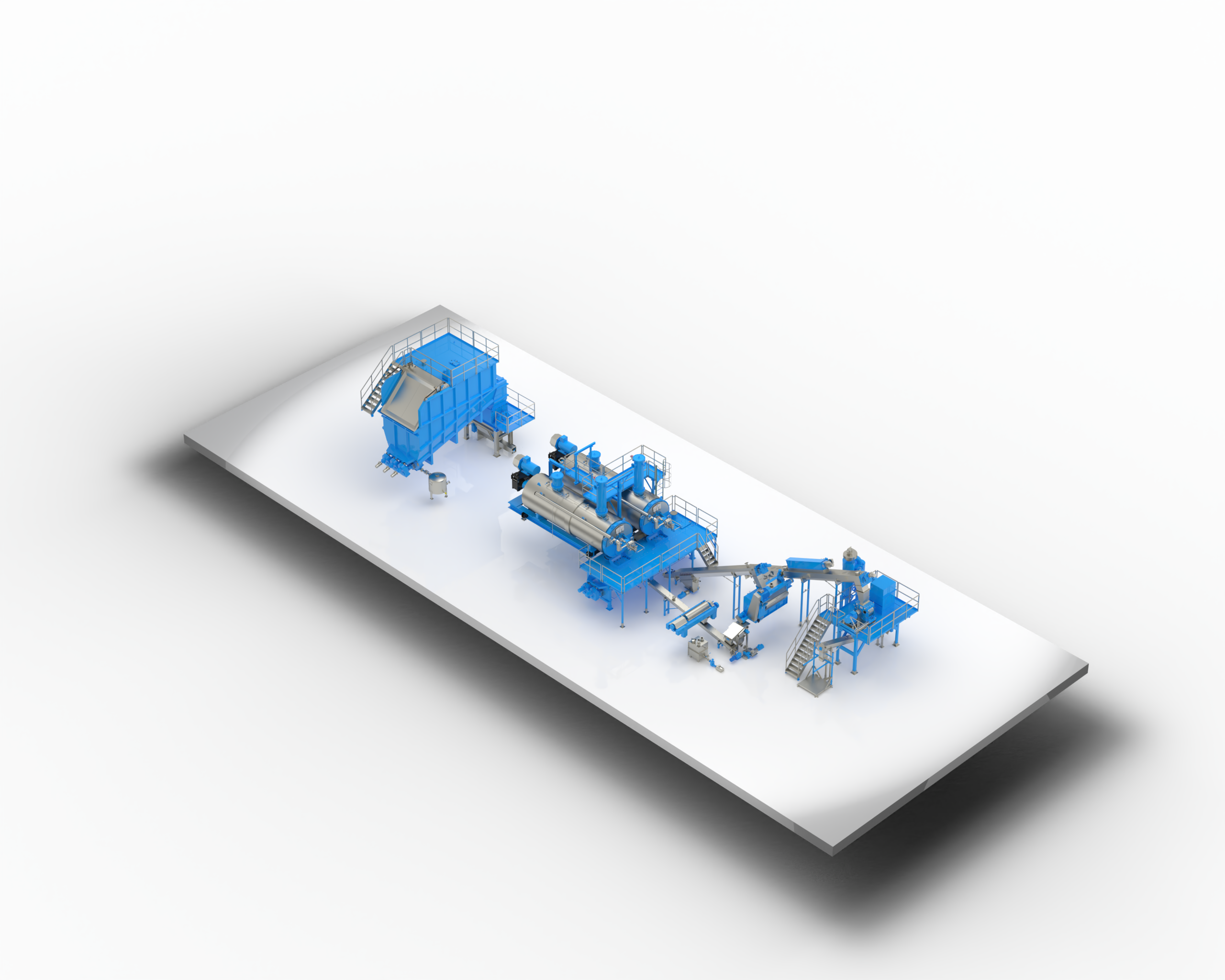

The rendering process starts with the collection of raw animal materials, such as bones, fat, and meat scraps. These materials are often sourced from meat processing plants, butcher shops, and slaughterhouses. The raw materials are then transported to the rendering facility for further processing.

Pre-Processing

Before the rendering process can begin, the raw materials must be pre-processed. This involves removing any unwanted materials, such as hair, feathers, and foreign objects. The materials are then ground into smaller pieces to facilitate the cooking and drying process.

Cooking and Drying

The pre-processed materials are then cooked and dried in large vessels called rendering cookers. The cookers are heated to high temperatures, typically between 240 and 300 degrees Fahrenheit, to break down the raw materials and extract the fat. The cooking process can take several hours depending on the type and amount of raw materials being rendered.

Separation of Solids and Liquids

After cooking, the mixture of solids and liquids is separated. The liquid fat, also known as tallow or grease, is drained from the cookers and stored in tanks for further processing. The remaining solids, known as meat and bone meal, are dried and ground into a powder. This powder is often used as a protein source in animal feed.

Overall, the rendering process is a crucial step in the utilization of animal by-products. It allows for the extraction of valuable materials such as fat and protein, while also reducing waste and minimizing environmental impact.

Types of Rendering

Wet Rendering

Wet rendering is a process that involves heating animal fat and tissue in the presence of water. This method is commonly used for processing fatty animal by-products such as meat trimmings, bones, and internal organs. During the wet rendering process, the animal parts are cooked in large vats of water, which causes the fat to melt and separate from the protein and other solids. The resulting mixture is then filtered to remove any remaining impurities, and the fat is further processed to remove any water or other contaminants.

Wet rendering is a popular method for producing high-quality animal fats that are used in a variety of applications, including food production, cosmetics, and industrial manufacturing. The fats produced through wet rendering are typically lower in free fatty acids and have a more consistent quality than those produced through dry rendering.

Dry Rendering

Dry rendering is a process that involves heating animal fat and tissue in the absence of water. This method is commonly used for processing leaner animal by-products such as bones and hides. During the dry rendering process, the animal parts are cooked in large ovens or tanks, which causes the fat to melt and separate from the protein and other solids. The resulting mixture is then filtered to remove any remaining impurities, and the fat is further processed to remove any water or other contaminants.

Dry rendering is a popular method for producing animal fats that are used in a variety of applications, including food production, cosmetics, and industrial manufacturing. The fats produced through dry rendering are typically higher in free fatty acids and have a more variable quality than those produced through wet rendering. However, dry rendering is often more cost-effective than wet rendering, making it a popular choice for many manufacturers.

Equipment Used

Grinders and Shredders

Meat rendering requires specialized equipment to properly process animal by-products. Grinders and shredders are essential in breaking down the raw materials into smaller, more manageable pieces. These machines come in various sizes and capacities and are designed to handle different types of materials. They are equipped with sharp blades that grind and shred the material into smaller pieces.

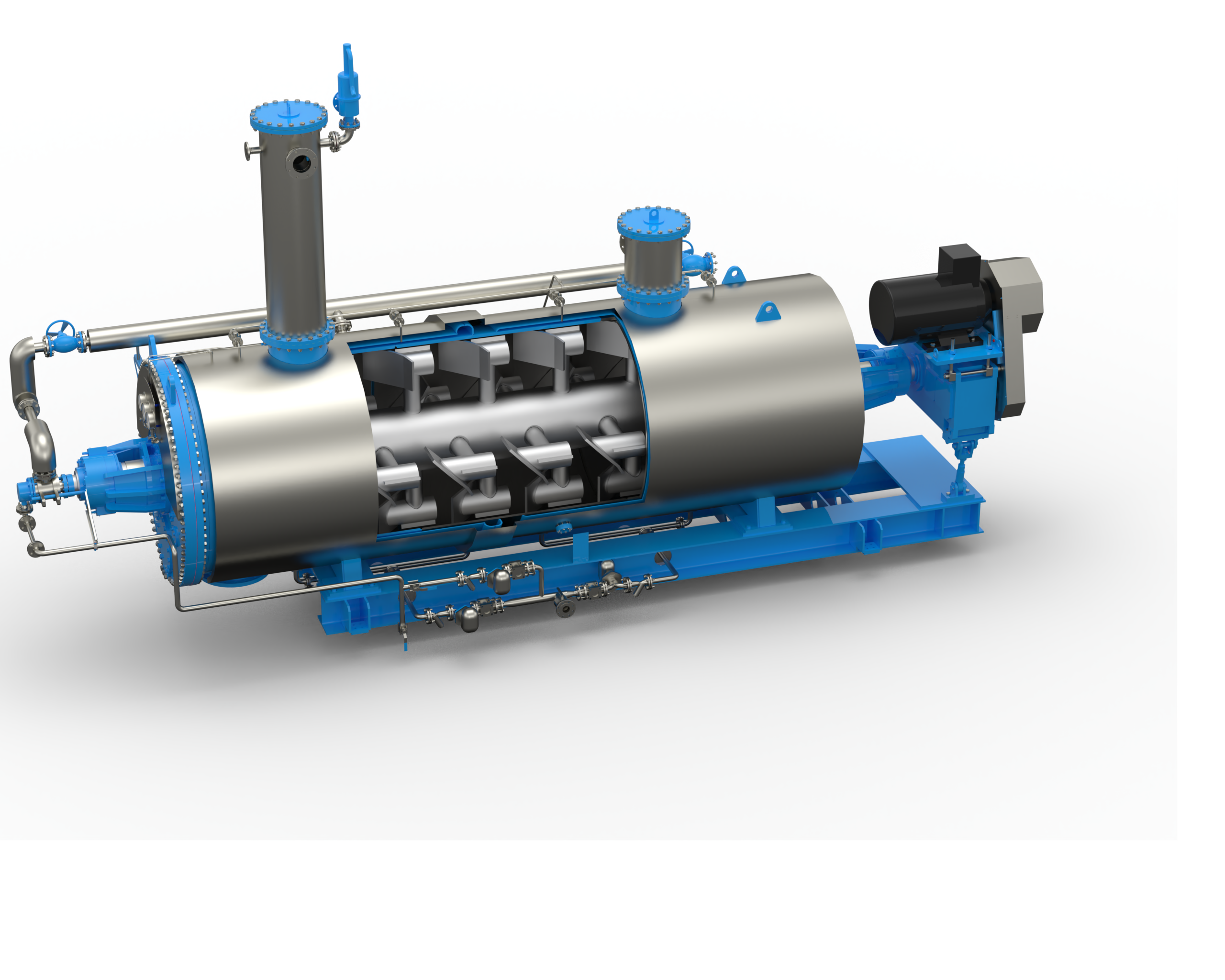

Cookers and Dryers

Cookers and dryers are used to remove moisture and fat from the meat by-products. These machines use high temperatures to break down the protein and fat molecules, making it easier to separate the fat from the protein. Cookers and dryers come in different sizes and configurations, and some are designed to handle specific types of materials.

Centrifuges and Presses

Centrifuges and presses are used to separate the fat from the protein. Centrifuges use centrifugal force to separate the fat from the protein, while presses use pressure to extract the fat. These machines are critical in the rendering process as they ensure that the final product is of high quality and meets industry standards.

Overall, the equipment used in meat rendering is designed to handle different types of materials and perform specific functions. The proper use and maintenance of these machines are essential in producing high-quality products that meet industry standards.

Products and Byproducts

Tallow and Grease

Rendering animal fats produces tallow and grease, which are widely used in various industries. Tallow is a common ingredient in soap, candles, and cosmetics, while grease is used in lubricants, biodiesel, and animal feed. Tallow is a solid fat obtained from beef or mutton, while grease is a semi-solid fat obtained from pork or poultry. Both tallow and grease are high in saturated fats and can be used as a substitute for vegetable oils in cooking.

Meat and Bone Meal

Meat and bone meal is a byproduct of meat rendering that is used as a source of protein and minerals in animal feed. It is made from the bones, meat, and other tissues that are not suitable for human consumption. Meat and bone meal is rich in protein, calcium, and phosphorus, making it an ideal ingredient in pet food and livestock feed. However, it can also contain contaminants such as heavy metals, pesticides, and antibiotics, which can be harmful to animals if consumed in large amounts.

Protein Meals

Protein meals are a type of meat and bone meal that has been further processed to remove most of the fat and moisture. They are high in protein and are used as a supplement in animal feed to improve the nutritional quality. Protein meals are made from various animal sources, including beef, pork, poultry, and fish. They are commonly used in aquaculture, poultry, and swine diets. However, protein meals can also contain contaminants, such as dioxins and PCBs, which can be harmful to animals and humans if consumed in large amounts.

In conclusion, meat rendering produces various products and byproducts that are widely used in different industries. Tallow and grease are used in soap, candles, lubricants, and animal feed, while meat and bone meal and protein meals are used as a source of protein and minerals in animal feed. However, it is essential to ensure that these products are safe and free from contaminants before using them in animal feed or other applications.

Quality Control

Standards and Regulations

Meat rendering is a process that requires strict adherence to quality control measures to ensure the safety and quality of the final product. There are several standards and regulations in place to govern the rendering process, including the Food and Drug Administration (FDA) regulations, the National Renderers Association (NRA) guidelines, and the American Fats and Oils Association (AFOA) standards.

The FDA regulations require that rendered animal products be free from harmful substances, such as heavy metals, pesticides, and antibiotics. The NRA guidelines provide recommendations for the rendering process, including the proper handling of raw materials and the use of equipment and facilities that meet specific criteria. The AFOA standards specify the quality and purity requirements for rendered animal products, including the maximum levels of impurities and contaminants that are allowed.

Testing Methods

To ensure compliance with these standards and regulations, various testing methods are used throughout the rendering process. These methods include chemical analysis, microbiological testing, and sensory evaluation.

Chemical analysis involves the use of laboratory equipment to measure the levels of various substances in the rendered product, such as protein, fat, moisture, and ash. Microbiological testing is used to detect the presence of harmful bacteria and other microorganisms in the rendered product, which can cause illness or spoilage. Sensory evaluation involves the use of trained panelists to evaluate the appearance, texture, and flavor of the final product.

Overall, the strict quality control measures and testing methods used in the rendering process ensure that the final product is safe, high-quality, and meets the necessary standards and regulations.

Environmental Impact

Meat rendering is a process that involves converting animal by-products into useful materials such as fats, oils, and proteins. While it has many benefits, it also has a significant impact on the environment. This section explores the environmental impact of meat rendering, with a focus on emission control and waste management.

Emission Control

Meat rendering involves the use of high temperatures to melt fat and separate it from other materials. This process releases a significant amount of greenhouse gases, including carbon dioxide, methane, and nitrous oxide. These gases contribute to climate change and have a negative impact on the environment.

To address this issue, meat rendering plants use various emission control measures. These include installing air pollution control equipment, such as scrubbers and filters, to remove harmful gases from the air. They also use energy-efficient equipment and processes to reduce energy consumption and minimize greenhouse gas emissions.

Waste Management

Meat rendering generates a significant amount of waste, including animal carcasses, bones, and other by-products. This waste can pose a threat to the environment if not managed properly. For example, it can attract pests, contaminate soil and water, and emit foul odors.

To address this issue, meat rendering plants use various waste management strategies. These include recycling and reusing by-products, such as using animal fat to produce biodiesel fuel. They also use proper disposal methods, such as composting and landfilling, to minimize the impact of waste on the environment.

In conclusion, meat rendering has a significant impact on the environment, particularly in terms of emission control and waste management. However, with proper measures in place, it is possible to minimize this impact and ensure that meat rendering remains a sustainable and responsible industry.

Applications of Rendered Products

Animal Feed

One of the most common uses of rendered products is as animal feed. Rendered animal fat and protein are valuable ingredients in livestock and pet food. These products are rich in essential nutrients that help animals grow and stay healthy. The protein in rendered products is also highly digestible, which means that animals can absorb more of it than they would from other protein sources.

Rendered products can be used in a variety of animal feeds, including poultry, swine, and aquaculture. In poultry feed, for example, rendered products can replace up to 50% of the soybean meal typically used as a protein source. This not only reduces the cost of feed production but also helps to conserve natural resources.

Industrial Uses

Rendered products are also used in a wide range of industrial applications. For example, animal fat can be used as a lubricant or as a raw material in the production of soaps, candles, and other products. Protein from rendered products can be hydrolyzed and used as a flavor enhancer in processed foods.

In addition, rendered products can be used as a source of energy in industrial boilers. The high energy content of animal fat makes it an attractive alternative to fossil fuels. This not only reduces the cost of energy but also helps to reduce greenhouse gas emissions.

Biofuel Production

Finally, rendered products can be used as a feedstock for the production of biodiesel. Biodiesel is a renewable fuel that can be used as a substitute for diesel fuel in transportation and other applications. Rendered animal fat is a particularly attractive feedstock for biodiesel production because it is readily available and has a high energy content.

In conclusion, rendered products have a wide range of applications, from animal feed to industrial uses to biofuel production. These products are valuable sources of protein and energy that help to conserve natural resources and reduce greenhouse gas emissions.