Oil Screw Press for Sale: Efficient and Affordable Extraction Solution

Oil Screw Press for Sale: Efficient and Affordable Extraction Solution

oil screw press for sale are a type of machinery used to extract oil from various seeds and nuts. These presses work by applying pressure to the seeds or nuts in order to extract the oil from them. The extracted oil can then be used for a variety of purposes, including cooking, fuel, and industrial applications.

For those looking to purchase an oil screw press for sale, there are a variety of options available on the market. These presses come in different sizes and capacities, and can be used for different types of seeds and nuts. Some of the most popular types of oil screw presses for sale include hydraulic screw presses, manual screw presses, and automatic screw presses.

When choosing an oil screw press for sale, it is important to consider factors such as the intended use, the type of seeds or nuts being processed, and the desired output. Additionally, it is important to purchase from a reputable supplier in order to ensure the quality and reliability of the machinery. With the right oil screw press for sale, individuals and businesses can efficiently extract oil for their needs.

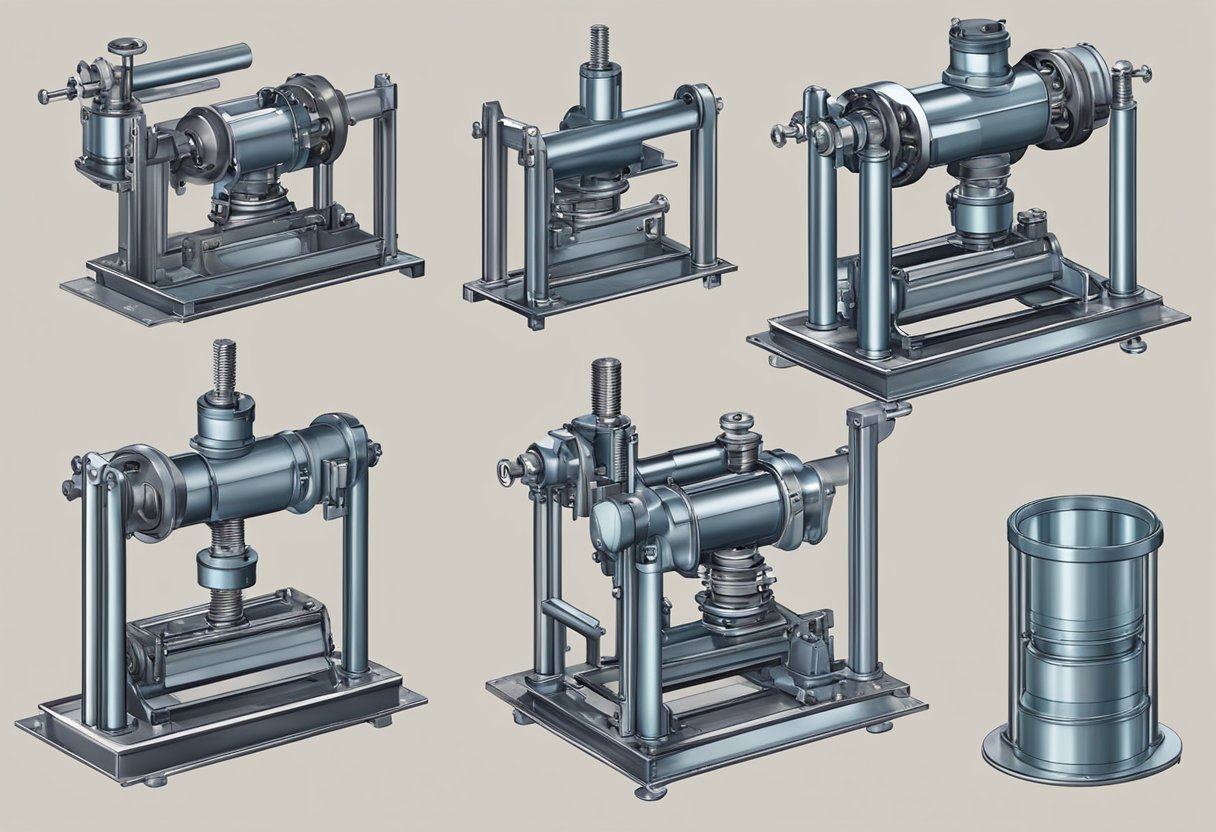

Overview of Oil Screw Presses

Oil screw presses are machines that are used to extract oil from various types of seeds such as soybean, sunflower, cottonseed, rapeseed, and peanut. The screw press works by using pressure and friction to compress the seeds and extract the oil. This process is known as mechanical extraction.

Oil screw press for sale come in different sizes and capacities to meet the needs of different users. They are commonly used in small-scale and large-scale oil production plants. The machines are easy to operate and require minimal maintenance, which makes them a popular choice among farmers and entrepreneurs.

The screw press is made up of several components, including a hopper, screw shaft, press cage, and electric motor. The hopper is used to feed the seeds into the machine, while the screw shaft rotates to compress the seeds and extract the oil. The press cage is where the oil and the cake are separated, while the electric motor provides the power to run the machine.

Oil screw presses are known for their high oil yield and low residual oil content in the cake. This means that a significant amount of oil can be extracted from the seeds, leaving behind a small amount of oil in the cake. The cake can be used as animal feed or as a fertilizer.

Oil screw press for sale are an efficient and reliable way to extract oil from various types of seeds. They are easy to operate and require minimal maintenance, making them a popular choice among users. With their high oil yield and low residual oil content, they are an excellent investment for anyone looking to produce oil on a small or large scale.

Types of Oil Screw Presses

There are several types of oil screw presses available in the market. Each type has its own unique features and benefits. In this section, we will discuss the three main types of oil screw presses: hydraulic, mechanical, and cold oil press.

Hydraulic Oil Press

Hydraulic oil presses are designed to extract oil from various seeds and nuts. They are operated by hydraulic pressure and can produce high-quality oil with minimal processing. Hydraulic oil presses are ideal for small-scale oil production and are easy to operate and maintain.

Mechanical Oil Press

Mechanical oil presses are powered by electricity or diesel engines and are used to extract oil from seeds and nuts. They are more efficient than hydraulic oil presses and can produce large quantities of oil in a short amount of time. Mechanical oil presses are suitable for medium to large-scale oil production.

Cold Oil Press

Cold oil presses are designed to extract oil from seeds and nuts without the use of heat. They are ideal for producing high-quality, unrefined oil that retains its natural flavor and nutrients. Cold oil presses are perfect for small-scale oil production and are easy to operate and maintain.

In conclusion, choosing the right type of oil screw press depends on the specific needs of the user. Hydraulic oil presses are ideal for small-scale production, while mechanical oil presses are more suitable for medium to large-scale production. Cold oil presses are perfect for producing high-quality, unrefined oil.

Key Features to Consider

When looking for an oil screw press for sale, there are several key features that one should consider. These features include the pressing capacity, operation mode, material quality, and safety features.

Pressing Capacity

The pressing capacity of an oil screw press refers to the amount of oil that can be extracted in a given amount of time. It is important to choose a machine with a pressing capacity that meets your needs. If you plan to use the press for commercial purposes, a higher pressing capacity will be necessary.

Operation Mode

The operation mode of an oil screw press can be either manual or automatic. Manual presses require more labor and are typically less expensive, while automatic presses are more efficient and require less labor. It is important to consider your needs and budget when choosing between manual and automatic operation modes.

Material Quality

The material quality of an oil screw press is important for durability and efficiency. It is recommended to choose a press made from high-quality materials such as stainless steel or cast iron. These materials are resistant to corrosion and can withstand high pressure and temperature.

Safety Features

Safety features are an important consideration when choosing an oil screw press. Look for features such as emergency stop buttons, safety guards, and automatic shut-off mechanisms. These features can help prevent accidents and ensure safe operation of the machine.

In summary, when looking for an oil screw press for sale, it is important to consider the pressing capacity, operation mode, material quality, and safety features. Choosing a machine with the right features can help ensure efficient and safe operation for your oil extraction needs.

Benefits of Using an Oil Screw Press

An oil screw press is a machine that extracts oil from seeds and nuts by pressing them under high pressure. This method of oil extraction has gained popularity due to its efficiency and quality of oil produced. Here are some benefits of using an oil screw press:

Efficiency Gains

Oil screw presses are designed to extract oil from seeds and nuts in a continuous and automated process. This means that once the machine is set up, it can run for hours without the need for human intervention. This leads to significant efficiency gains as it reduces labor costs and increases productivity.

Moreover, oil screw presses have a high oil extraction rate, which means that more oil is extracted from the seeds and nuts than other traditional methods. This results in higher yields and ultimately, more profits for the user.

Quality of Oil Produced

Oil screw presses produce high-quality oil that is free from impurities and additives. This is because the oil is extracted through a mechanical process that does not involve the use of chemicals or solvents. The oil is also extracted at low temperatures, which helps to preserve its nutritional value and flavor.

Additionally, oil screw presses can be adjusted to produce different grades of oil depending on the user’s needs. For example, the machine can be set to produce virgin oil, which is the highest quality oil, or refined oil, which has been processed to remove impurities.

Environmental Impact

Oil screw presses are environmentally friendly as they do not produce harmful emissions or waste. The machines are designed to be energy-efficient and consume less power than other traditional methods of oil extraction. This reduces the carbon footprint of the user and helps to preserve the environment.

Moreover, oil screw presses are designed to be durable and long-lasting, which reduces the need for frequent replacements. This reduces the amount of waste generated and ultimately, reduces the impact on the environment.

In conclusion, using an oil screw press has many benefits, including efficiency gains, high-quality oil production, and environmental sustainability. These benefits make it a popular choice for those looking to extract oil from seeds and nuts.

Oil Screw Press Applications

Oil screw presses are versatile machines that can be used in a variety of industries. Here are some of the most common applications:

Food Industry

Oil screw presses are widely used in the food industry for the extraction of edible oils from various seeds and nuts. These oils are used in the production of cooking oils, margarine, and other food products. The screw press is particularly useful for small and medium-sized businesses that produce their own oils on-site.

Cosmetics Production

In the cosmetics industry, oil screw presses are used to extract oils from various plants and seeds that are used in the production of cosmetics and personal care products. These oils are used in the formulation of skin creams, lotions, and hair care products. The screw press is an efficient and cost-effective way to extract these oils.

Biofuel Production

Oil screw presses are also used in the production of biofuels. The press can be used to extract oils from various crops such as soybeans, rapeseed, and sunflower seeds. These oils can then be converted into biodiesel, which is a renewable and environmentally friendly alternative to traditional diesel fuel.

Overall, oil screw presses are versatile machines that can be used in a variety of industries. They are efficient, cost-effective, and environmentally friendly, making them an attractive option for businesses looking to extract oils from various sources.

Maintenance and Cleaning

Routine Maintenance

To ensure the longevity and optimal performance of an oil screw press, routine maintenance is necessary. The following tasks should be performed regularly:

- Check the oil level and add oil as needed

- Inspect the belts for wear and tension

- Lubricate the bearings and other moving parts

- Tighten any loose bolts or screws

- Check the electrical connections and replace any damaged wires

Performing routine maintenance will help prevent breakdowns and costly repairs.

Cleaning Procedures

Proper cleaning of an oil screw press is crucial to maintain its efficiency and prevent contamination of the oil. The following steps should be followed:

- Turn off the machine and disconnect the power source.

- Remove any leftover oil and debris from the press.

- Use a cleaning solution to remove any buildup or residue from the press.

- Rinse the press thoroughly with water and allow it to dry completely.

- Wipe down the press with a clean, dry cloth.

It is important to note that harsh chemicals should not be used to clean the press, as they can damage the machine and contaminate the oil. Additionally, the cleaning solution should be food-grade and approved for use with oil presses.

By following these cleaning procedures, the oil screw press will continue to produce high-quality oil.

Troubleshooting Common Issues

Operational Problems

Oil screw presses are generally reliable machines, but like any mechanical equipment, they can experience issues from time to time. Here are some common operational problems and their solutions:

- Low oil yield: If the oil yield is lower than expected, it could be due to several reasons. One of the most common reasons is improper adjustment of the press. The gap between the press cage and the screw shaft should be adjusted based on the type and moisture content of the seeds being pressed. Another reason could be insufficient pressure or temperature during pressing. In such cases, the pressure and temperature should be increased to achieve better oil yield.

- Excessive oil residue: If there is excessive oil residue in the cake, it could be due to inadequate pressing. This could be caused by insufficient pressure or temperature during pressing or improper adjustment of the press cage. Increasing the pressure and temperature or adjusting the press cage can help reduce the oil residue.

- Excessive wear and tear: Excessive wear and tear of the screw shaft and press cage can lead to reduced efficiency and oil yield. This could be due to several reasons, including improper maintenance, use of inferior quality parts, and excessive load on the machine. Regular maintenance, use of quality parts, and avoiding overloading the machine can help prevent excessive wear and tear.

Mechanical Failures

Mechanical failures are less common but can be more serious. Here are some common mechanical failures and their solutions:

- Broken screw shaft: A broken screw shaft is a serious issue that requires immediate attention. This could be due to excessive load on the machine or use of inferior quality parts. The broken screw shaft should be replaced with a new one.

- Broken press cage: A broken press cage is also a serious issue that requires immediate attention. This could be due to excessive load on the machine or use of inferior quality parts. The broken press cage should be replaced with a new one.

- Motor failure: Motor failure is a less common but serious issue that could be due to several reasons, including overloading, overheating, and electrical issues. A qualified technician should be called to diagnose and repair the motor.

In conclusion, oil screw presses are reliable machines, but they can experience issues from time to time. Proper maintenance, use of quality parts, and avoiding overloading the machine can help prevent most issues.

Cost Analysis

Initial Investment

The initial investment for purchasing an oil screw press can vary depending on the size and type of press. Generally, smaller capacity presses are less expensive than larger ones. The cost can range from a few thousand to tens of thousands of dollars. It is important to consider the capacity of the press and the volume of oil production needed before making a purchase.

Operating Costs

The operating costs of an oil screw press include maintenance, labor, and energy costs. The maintenance cost can vary depending on the frequency of maintenance and the type of maintenance required. Labor costs can also vary depending on the size of the press and the number of workers needed to operate it. Energy costs are also a major operating cost as the press requires electricity to operate.

In addition to these costs, there may be other expenses such as transportation and storage costs for the oil produced. It is important to carefully consider all of these costs before purchasing an oil screw press to ensure that it is a financially viable investment.

Overall, while the initial investment for an oil screw press can be significant, careful consideration of operating costs can ensure that the investment is profitable in the long run.

Purchasing Guidelines

When looking to purchase an oil screw press, there are several factors to consider to ensure that you get the best value for your money. Here are some purchasing guidelines to follow:

Supplier Evaluation

Before making a purchase, it is important to evaluate the supplier to ensure that they are reputable and reliable. Look for a supplier who has a proven track record of providing high-quality oil screw presses. You can check their website and read reviews from previous customers to get an idea of their reputation.

Another important factor to consider is the supplier’s location. It is recommended to choose a supplier who is located near your business to minimize transportation costs and ensure timely delivery.

Warranty and Support

When purchasing an oil screw press, it is important to consider the warranty and support offered by the supplier. Look for a supplier who offers a warranty that covers the product for a reasonable amount of time. This will give you peace of mind knowing that you are protected in case of any defects or malfunctions.

In addition, it is important to consider the level of support offered by the supplier. Look for a supplier who offers customer support and technical assistance to help you with any issues that may arise. This will ensure that you are able to use your oil screw press efficiently and effectively.

By following these purchasing guidelines, you can ensure that you make an informed decision when purchasing an oil screw press.

Installation and Setup

Space Requirements

Before purchasing an oil screw press, it is important to consider the space requirements for installation. The size of the press will vary depending on the model and capacity, so it is essential to measure the available space accurately. It is recommended to leave some extra space around the press for easy access during maintenance and cleaning.

Installation Process

The installation process of an oil screw press is relatively simple and can be completed by a professional technician. The following steps are generally involved in the installation process:

- Preparation of the foundation: The foundation should be level and strong enough to support the weight of the press and the oil tanks. The foundation should also be able to withstand the vibrations produced during the operation of the press.

- Assembly of the press: The press should be assembled according to the manufacturer’s instructions. All the components should be securely fastened, and the press should be properly aligned.

- Connection of the power supply: The press should be connected to a reliable power supply that meets the voltage and frequency requirements specified by the manufacturer.

- Connection of the oil tanks: The oil tanks should be connected to the press according to the manufacturer’s instructions. The oil tanks should be placed at a suitable distance from the press to avoid any interference during operation.

- Testing and commissioning: Once the press is installed, it should be tested and commissioned by a professional technician. The technician should check the alignment, the power supply, and the oil tanks to ensure that everything is working correctly.

In conclusion, the installation and setup of an oil screw press require careful consideration of the space requirements and proper installation by a professional technician. Following the manufacturer’s instructions and guidelines is essential to ensure the safe and efficient operation of the press.

Regulations and Compliance

Industry Standards

Oil screw press manufacturers must comply with industry standards to ensure the safety and quality of their products. These standards are set by organizations such as the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO). Compliance with these standards is often a requirement for the sale of oil screw presses.

ASME standards cover the design, fabrication, and inspection of pressure vessels, including oil screw presses. Compliance with these standards ensures that the equipment is safe to use and meets the necessary quality requirements. ISO standards cover a wide range of topics, including quality management, environmental management, and occupational health and safety. Compliance with ISO standards demonstrates a commitment to quality and environmental responsibility.

Certifications

In addition to complying with industry standards, oil screw press manufacturers may obtain certifications to further demonstrate their commitment to quality and safety. One such certification is the CE Mark, which indicates that a product meets the safety, health, and environmental requirements of the European Union. Another certification is the UL Mark, which indicates that a product has been tested and meets safety standards set by Underwriters Laboratories.

Manufacturers may also obtain certifications specific to the oil and gas industry, such as the American Petroleum Institute (API) Monogram. This certification indicates that a product meets API standards for design, manufacturing, and testing. Compliance with API standards ensures that the equipment is suitable for use in the oil and gas industry and meets the necessary safety and quality requirements.

Overall, compliance with industry standards and obtaining certifications demonstrates a commitment to quality and safety in the manufacturing of oil screw presses.