Sunrise rendering plant

Cross-country delivery in progress! Customized production line for Russian customer completed plastic packing, about to set sail!

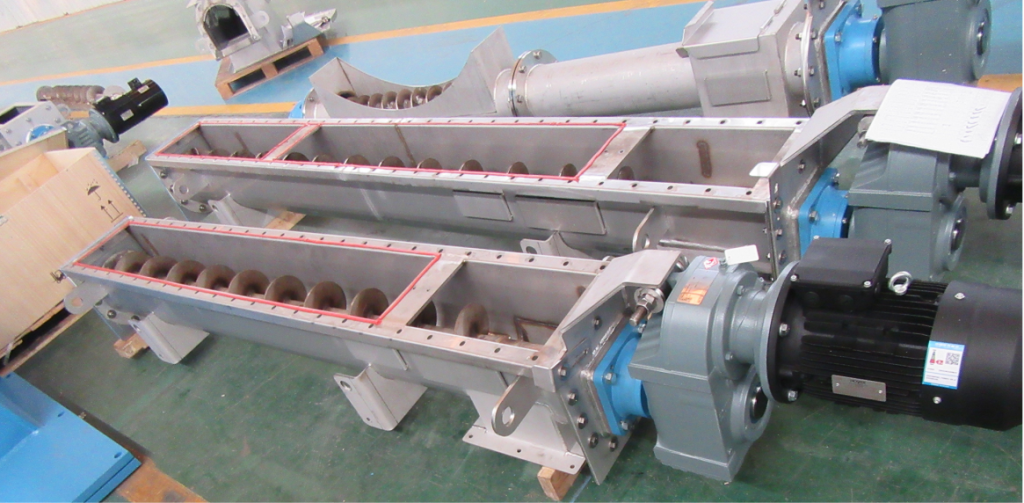

Recently, the customized pig slaughter waste treatment production line for our Russian customer has been fully completed and has passed the strict product inspection process.

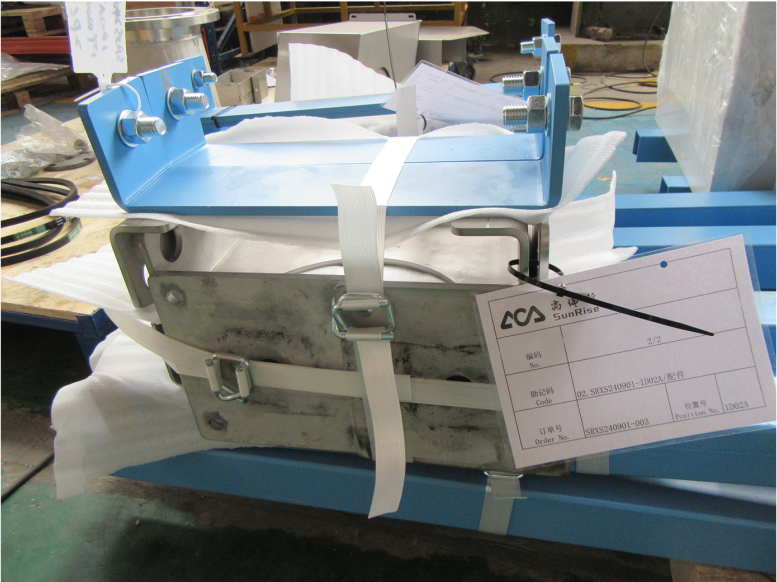

At present, the equipment has completed the vacuum – sealing and packing operation, and has been formally loaded and sent to the port, and is about to start its transnational transportation journey.

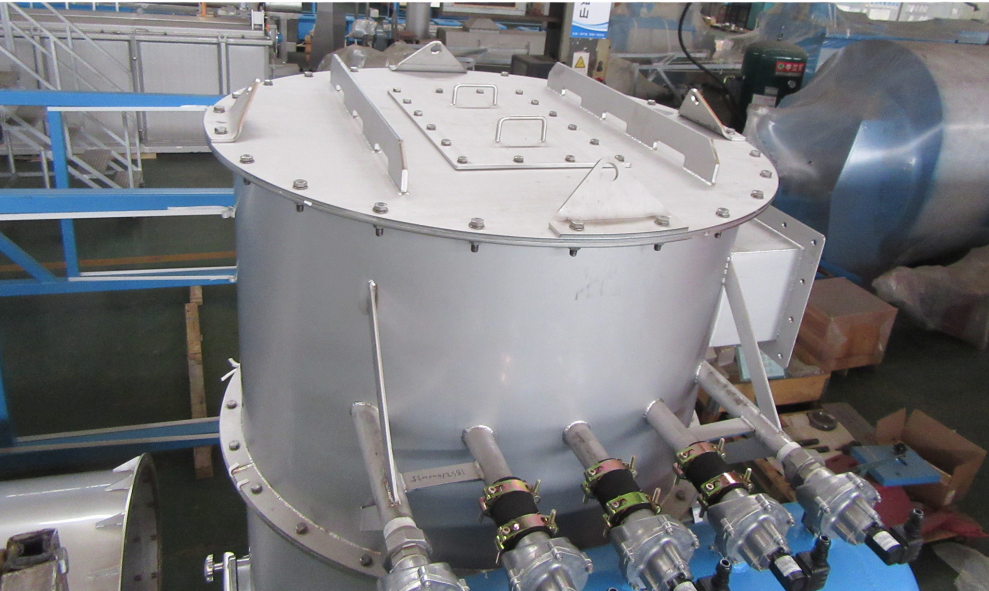

This set of customized treatment equipment can process pig slaughter wastes such as internal organs, bones, blood, minced meat, tails and other materials into animal protein and animal oil after high – temperature and high – pressure disinfection and sterilization, realizing the closed – loop resource utilization of slaughter wastes.

Project Highlights Analysis

Customized Technology Adaptation

Aiming at the characteristics of wastes in the Russian pig slaughter industry, the production line is equipped with a pre – treatment system, a high – temperature sterilization device and a resource recovery module, which can realize the reduction, harmlessness and resource utilization of slaughter wastes, meeting the Russian environmental protection standards and the customer’s production capacity requirements.

Full – process Quality Control

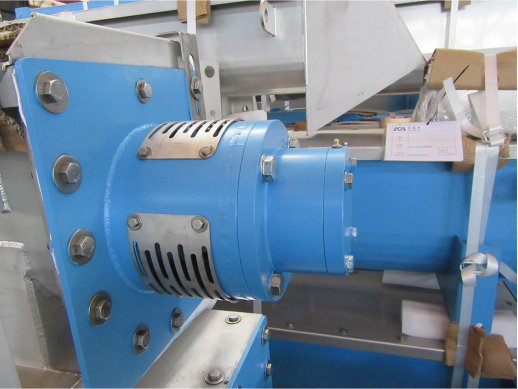

During the production stage, it has undergone multiple rounds of inspections such as mechanical precision testing, automatic operation debugging, and environmental protection index acceptance, ensuring that the equipment can still operate stably in low – temperature environments. Key components have all passed the corrosion – resistance and wear – resistance performance verification.

Cross – border Delivery Guarantee

The packaging link adopts a moisture – proof sealing + shock – proof steel frame structure, suitable for long – distance sea and land transportation needs; at the same time, the preparation of customs clearance documents has been completed simultaneously to ensure quick customs clearance after the equipment arrives.

The delivery of this production line not only realizes the “turning waste into treasure” of slaughter wastes, converting wastes into valuable products such as animal feed, organic fertilizer raw materials, and industrial oil, but also provides a demonstration case for Sino – Russian environmental protection technology cooperation. In the follow – up, our company will provide remote debugging guidance and localized after – sales support to help customers achieve efficient operation of waste treatment.

If you need to know the details of equipment operation or solutions for similar projects, you can contact us at any time to obtain detailed information.

Categories

Recent Posts

-

Sunrise Batch Cooker: The Preferred Solution for Harmless Treatment of Animal By-Products

December 19, 2025 -

100,000 pigs culled! Vietnam’s swine fever exposes shortcomings in safe handling

October 24, 2025 -

Five Steps to Efficient Cattle Dead Handling on Cattle Farms:SunRise Helps with Compliance and Loss Reduction

October 9, 2025