Introduction to Pre-Crushers: Revolutionizing Waste Management

Introduction to Pre-Crushers: Revolutionizing Waste Management

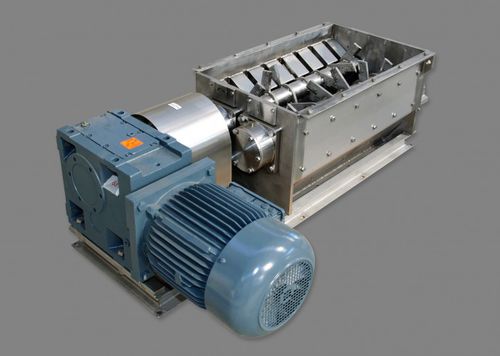

In today’s world, effective waste management is more important than ever. Businesses and industries produce a significant amount of waste daily, and finding innovative solutions to reduce waste volume and optimize disposal processes is crucial. This is where pre-crushers come into play. Pre-crushers, also known as pre-crusher compactors, are powerful machines designed to handle bulky and difficult-to-manage refuse. By pre-crushing waste products before compacting, pre-crushers enable businesses to minimize waste volume, increase load weights, and ultimately reduce disposal costs.

Understanding Pre-Crushers

Pre-crushers are specifically designed to process bulky waste and materials in advance of compacting them into containers. The primary goal is to effectively reduce waste volume and increase load weights, resulting in more efficient waste management. These machines are ideally suited for crushing drums, pallets, furniture, white goods, and even destroying merchandise to prevent scavenging or reuse.

The Benefits of Pre-Crushers

Pre-crushers offer numerous benefits for businesses and industries looking to optimize their waste management processes. Let’s explore some of the key advantages:

1. Waste Volume Reduction

One of the primary benefits of pre-crushers is their ability to significantly reduce waste volume. By pre-crushing bulky waste items, such as furniture or pallets, pre-crushers break them down into smaller pieces, effectively reducing their overall volume. This reduction in waste volume allows businesses to maximize their container space and minimize the frequency of waste pickups, resulting in cost savings.

2. Increased Load Weights

In addition to waste volume reduction, pre-crushers also increase load weights. By breaking down bulky waste items, pre-crushers create denser loads, maximizing the capacity of each container. This means that businesses can transport and dispose of more waste in a single trip, optimizing their transportation costs and reducing their carbon footprint.

3. Cost Savings

With reduced waste volume and increased load weights, businesses can experience significant cost savings in waste disposal. By optimizing container space and transportation efficiency, pre-crushers help reduce the frequency of waste pickups, resulting in lower hauling costs. Additionally, pre-crushers can prevent scavenging or reuse of destroyed merchandise, protecting businesses from potential losses.

Features of Pre-Crushers

Now that we understand the benefits of pre-crushers, let’s delve into the key features that make these machines effective waste management solutions.

1. Heavy-Duty Construction

Pre-crushers are built to withstand heavy-duty industrial applications. SolidWorks computer software is used to structurally design these machines, ensuring their durability and reliability. The robust construction allows pre-crushers to handle even the toughest waste materials without compromising their performance.

2. Reinforced Pre-Crusher Gate

The reinforced gate design of pre-crushers enables them to reliably withstand the forces required to crush and destroy various materials, including drums, pallets, furniture, and white goods. This ensures consistent performance and prevents any potential damage to the machine during the waste management process.

3. Tongue and Groove Floor

To prevent waste material from migrating between the ram and compactor floor, all Cram-A-Lot pre-crusher compactor models feature a tongue and groove floor. This design feature ensures optimal compaction and prevents any waste material from escaping the compression process, resulting in more efficient waste management.

4. Programmable Logic Controller

Reliability is a critical aspect of waste management equipment, and pre-crushers are no exception. To ensure consistent performance and simplify electrical circuit design, pre-crushers are equipped with a programmable logic controller (PLC). The PLC streamlines the operation of the machine, eliminating the need for relays and providing a more reliable and durable hydraulic system.

Power Unit Design & Construction

The hydraulic power unit is the heart of any compactor, including pre-crushers. At Cram-A-Lot, the power units are designed and built in-house, specifically for their applications. This ensures the reliability and performance that customers deserve. The Power Source IHM system, a key feature of Cram-A-Lot’s pre-crusher compactor power units, provides a more compact and efficient hydraulic system. By reducing the size and weight of the power unit, it enhances the overall performance and durability of the machine.

Hydraulic Cylinders: Ensuring Reliability

Hydraulic cylinders play a crucial role in the operation of pre-crushers. They are responsible for exerting the force required to crush and compact waste materials effectively. Given their importance, it is essential to source high-quality cylinders to ensure the reliability and longevity of the machine.

At Cram-A-Lot, the cylinders used in their pre-crushers are sourced from a trusted supplier, and they have maintained the same specification for over 20 years. These cylinders are made in the USA and designed to last. By prioritizing quality and reliability over cost-cutting measures, Cram-A-Lot ensures that their customers receive a superior product that meets their waste management needs.

In conclusion, pre-crushers are powerful waste management machines designed to handle bulky and difficult-to-manage refuse. By pre-crushing waste products before compacting, businesses can reduce waste volume, increase load weights, and optimize their waste management processes. The key features, such as heavy-duty construction, reinforced gates, tongue and groove floors, and programmable logic controllers, make pre-crushers reliable and efficient machines. Moreover, the in-house design and construction of power units and the use of high-quality hydraulic cylinders ensure the reliability and longevity of pre-crushers. Investing in pre-crushers can revolutionize waste management practices, leading to cost savings, environmental benefits, and streamlined operations.Pre-crusher