Market Insights and Future Prospects of Rendering Plant Machinery

Market Insights and Future Prospects of Rendering Plant Machinery

Rendering plant machinery plays an important role in the animal by-products industry, which is gaining more attention as the market evolves. Manufacturers like Sunrise are stepping into the spotlight, catering to increasing demand for advanced rendering solutions. As buyers and investors seek to make informed decisions in a dynamic market, understanding the latest trends, demand projections, and the innovative developments shaping the future of rendering plant machinery becomes essential. This blog delves into the trends, projections and developments in rendering plant machinery with a particular focus on Sunrise’s contributions.

In recent years, technology has become the driving force behind innovation in rendering plant machinery. Sunrise’s dedication to integrating the latest technological advancements within its machinery has not only enhanced operational efficiency but has also opened doors to new possibilities. From automated systems that monitor and control rendering processes in real time to predictive analytics that optimize resource utilization, Sunrise’s machinery reflects the industry’s shift towards data-driven decision-making and improved overall performance.

Sunrise’s influence extends beyond borders, with their rendering plant machinery making a global impact. Rendering plants powered by Sunrise machinery are revolutionizing waste management practices in various industries, including agriculture, food processing, and more. By extracting maximum value from by-products, these solutions contribute to a more sustainable and resource-efficient world.

Market Trends Shaping the Rendering Industry: A Glimpse into the Present

The rendering industry has witnessed a paradigm shift in recent years, driven by various factors. Sustainability concerns, increased emphasis on resource optimization, and the growing need for eco-friendly waste management practices have propelled the demand for rendering plant machinery. In this landscape, one name that stands out is Sunrise, a leading manufacturer known for its innovative rendering solutions.

The global emphasis on sustainability and eco-friendly practices has catalyzed a surge in demand for rendering plant machinery. As industries across the globe recognize the importance of efficient waste management and the conversion of organic byproducts into valuable resources, the rendering industry stands at the forefront of this transformation. Sunrise has positioned itself as a key player in meeting this demand, offering cutting-edge solutions that not only streamline rendering processes but also contribute to a greener, more sustainable future.

Sunrise: Pioneering Evolution in Rendering Plant Machinery

Rendering processes vary across industries, necessitating machinery that can adapt to diverse requirements. Here, Sunrise excels with its range of customizable machinery options. Two-level headline Whether it’s poultry, livestock, or fish rendering, Sunrise’s machinery can be tailored to meet the specific demands of each industry. This flexibility ensures that rendering processes are not only efficient but also aligned with the unique characteristics of the materials being processed.

1. Innovation in Processing: Enhancing Efficiency and Yield

Sunrise has revolutionized the rendering plant machinery sector through its innovative approaches. Their machinery is designed to maximize efficiency in the rendering process while minimizing waste and energy consumption. The integration of cutting-edge technologies like automation, data analytics, and real-time monitoring has elevated the efficiency of rendering plants to unprecedented levels.

2. Meeting Stringent Environmental Standards: A Commitment to Sustainability

Sustainability is a key driver in today’s industrial landscape. Sunrise has aligned its rendering plant machinery with the highest environmental standards. Their systems are equipped with advanced filtration and waste treatment mechanisms that ensure minimal environmental impact. This dedication not only resonates with responsible waste management practices but also aligns with the preferences of eco-conscious industries.

Forecasting the Future: Rendering Plant Machinery Market Outlook

The rendering industry is poised for further advancements, and Sunrise is at the forefront of driving these innovations. With a focus on sustainability, efficiency, and adaptability, the company is anticipated to continue unveiling machinery that pushes the boundaries of what’s possible in rendering. From improved energy efficiency to the incorporation of emerging technologies like artificial intelligence and blockchain for enhanced traceability, Sunrise is likely to play a pivotal role in shaping the industry’s landscape for years to come.

1. Technological Advancements: Shaping the Path Ahead

The future of rendering plant machinery envisions a seamless amalgamation of technology and functionality. As the industry marches towards Industry 4.0, smart rendering solutions are expected to take center stage. AI-driven process optimization, remote monitoring, and predictive maintenance are anticipated to become integral components of rendering plants, optimizing operations and minimizing downtime.

2. Global Expansion of Rendering Practices: Opportunities and Challenges

The global rendering industry is expanding, fueled by the increasing demand for meat products and the need for sustainable waste management. This expansion presents both opportunities and challenges for rendering plant machinery manufacturers. Sunrise, with its robust experience and forward-looking approach, is poised to cater to this growing demand while addressing challenges such as regulatory variations and cultural nuances across different markets.

Efficiency Redefined: Key Features of Sunrise Rendering Plant Machinery

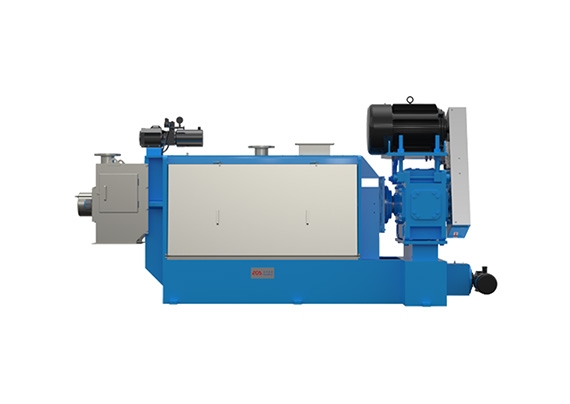

1. State-of-the-Art Processing Units

Sunrise rendering plant machinery boasts state-of-the-art processing units that efficiently convert animal by-products into valuable materials. Through meticulous engineering, these units maximize yield while adhering to the highest safety standards.

2. Energy-Efficient Systems

A commitment to sustainability drives Sunrise’s machinery design. Their energy-efficient systems not only reduce operational costs but also contribute to a greener planet. The incorporation of advanced heat recovery systems and optimized energy consumption sets their machinery apart.

3. Advanced Automation and Monitoring

Embracing the Industry 4.0 revolution, Sunrise integrates advanced automation and monitoring into their rendering plant machinery. Real-time data analysis, remote access, and predictive maintenance ensure uninterrupted operation and swift issue resolution.

Conclusion: Investing in the Future of Rendering Plant Machinery

In conclusion, the rendering industry is undergoing a transformative phase, and rendering plant machinery is at the heart of this evolution. Sunrise, a prominent manufacturer in this domain, has been instrumental in driving innovation, efficiency, and sustainability within the industry. As market trends point towards heightened demand and increasing technological integration, investing in cutting-edge rendering plant machinery from manufacturers like Sunrise can yield long-term benefits for industries across the globe. For those looking to make informed investment decisions, keeping an eye on these market trends and the pioneering work of manufacturers like Sunrise is crucial in staying ahead in the rendering industry’s dynamic landscape.