Revolutionizing the Fish industry with fish meal machine

Revolutionizing the Fish industry with fish meal machine

Introduction to fish meal:

Fishmeal is a crucial source of animal protein in feed. The fishmeal business in the nation needed to catch up in its growth. Still, in recent years, with the rise in the production of low-quality, high-yield fish and the advancement of animal husbandry, the need for feed has skyrocketed, and the fishmeal processing sector has grown quickly. A wide range of circumstances influences the quality of fishmeal, which is strongly tied to the quality of feed items. The choice of fishmeal equipment production lines and fishmeal processing technologies are two of them that are crucial for the quality of fishmeal.

What is meant by a fish meal machine?

The invention of the fish meal machine has caused a considerable shift in the aquaculture sector. The production of fish meals has been dramatically altered by this cutting-edge technology, which offers several advantages and benefits for the sector. Fish meal manufacture, Sunrise, has always been a labour- and time-intensive procedure. The fish feed has traditionally been produced using a labour- and time-intensive procedure. However, the landscape of fish feed manufacturing is changing due to the advent of the fish meal machine.

- Fish or other types of seafood are used to make fish meal, a type of animal feed. Fish and seafood are normally cooked, pressed, dried, and ground before being combined with preservatives and other substances to make it fit for ingestion.

- Fish meal is a key component of aquaculture since it has a long history of enhancing feeds and enhancing the health of aquaculture aquatic animals. Through its distinctive nutritional contribution, it has, over time, shown to be indispensable to the business.

- Fish meals are suitable for use as feed for animals. Through the extraction and refining procedures, it may also be transformed into products that are not oil-based.

Introducing the Fish Meal Machine, the perfect answer to all of your cooking problems

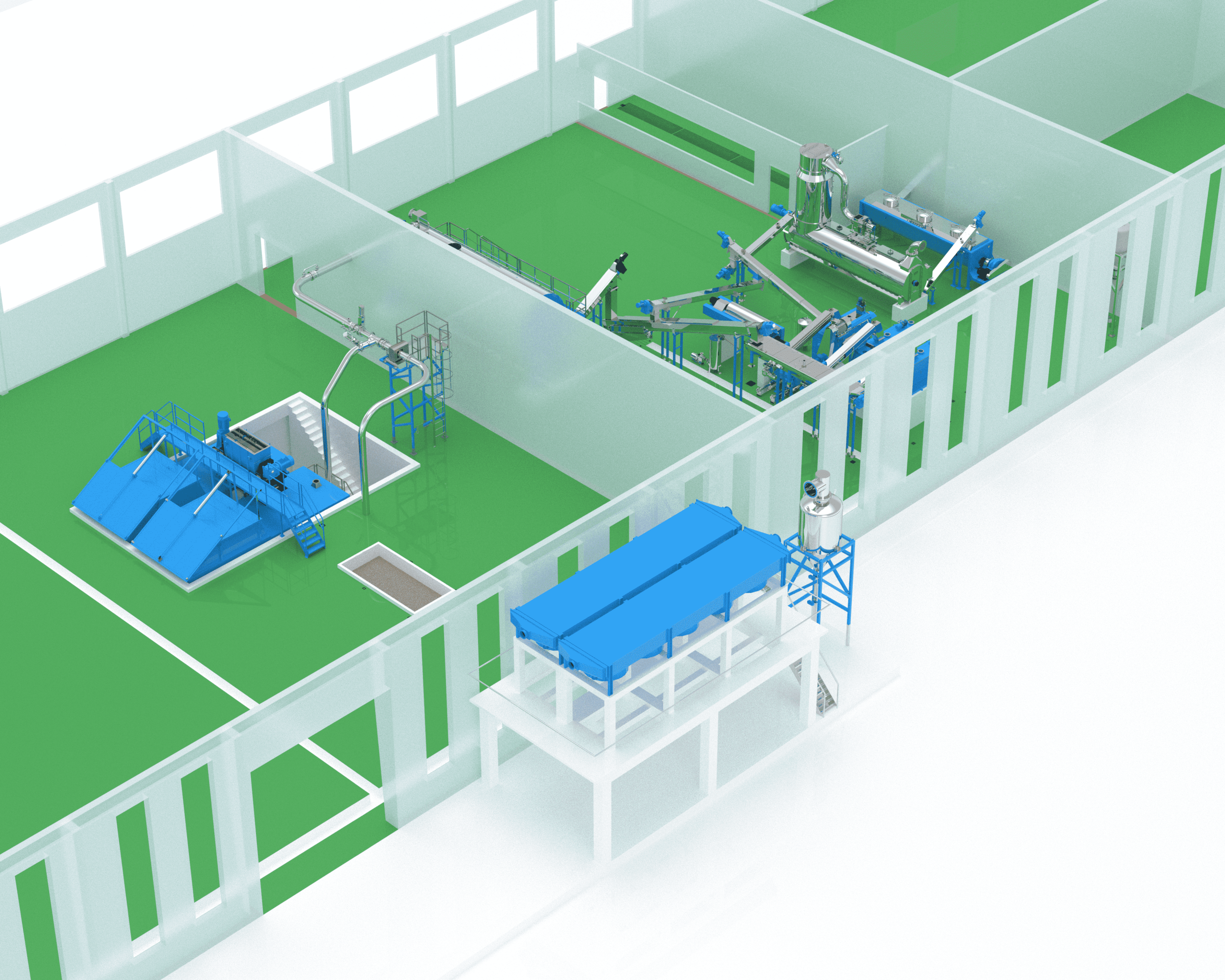

The production method for fish meals has undergone a radical transformation due to considerable technological breakthroughs in recent years. Increasing the effectiveness and quality of fish meal production has become essential due to the rising demand for fish meals as a valuable source of protein in animal feed and aquaculture. Fish waste is converted into valuable fish meal by fish meal machine, which are a significant part of the fish processing industry.

The method of preparing a fish meal

The dry and wet methods are the two primary categories of fishmeal processing techniques. Among these, the dry processing methods are further broken down into direct drying and dry pressing, and the wet processing methods into pressing, centrifugal, extraction, and hydrolysis.

- The oxidation of the oil is more severe, the fish meal produced is dark in colour, easily produces strange odours, and the protein content is not great, which affects the digestion of the feed since the dry processing technique demands long-term high-temperature drying of the raw materials. The benefit is that the equipment is straightforward, inexpensive, and appropriate for medium- and low-fat fish.

- The relative wet process uses more widely used fish meal processing equipment. The precooked raw materials are pressed, sorted, and dried before being used in this procedure. The manufactured fish meal is of higher grade and contains more protein. The cost is minimal, but a drawback is that small and medium-sized businesses must meet a somewhat high threshold and equipment investment costs are rather high.

What equipment is used in the fishmeal production line?

Since the wet process is now the most often utilised for processing fish meals, here we will primarily introduce all the equipment needed in the wet process’ fish meal plant production line. Although each method has unique traits and applications, the fish meal machine employed is limited to the following:

Cooking machine: To prepare the fish body for the ensuing pressing, cooking involves breaking up the fat cells, coagulating the protein, and completely releasing the oil and water from the fish body.

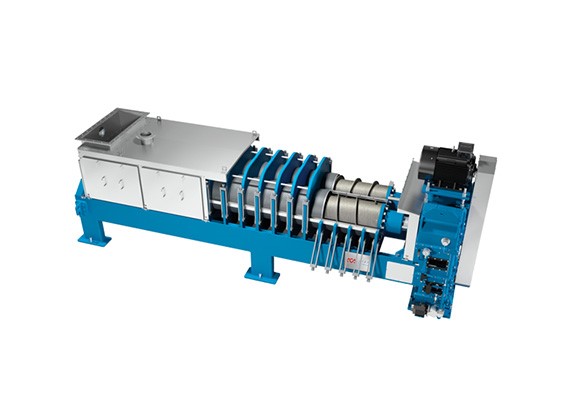

- Press:

To decrease the load on the dryer and the amount of steam used, extract most of the oil and moisture from the cooked item before drying it.

- Three-phase decanter centrifuge:

The three-phase decanter centrifuge may replace the press and help further reduce moisture content, fatty acid content, fish oil contaminants, and oil output by centrifuging the cooked material to separate oil, moisture, and solid residue. Product to make fish oil last longer in storage.

- Fishmeal Dryer:

Drying fishmeal is done to turn wet material into dry fishmeal. In most cases, fish meal has less than 12% moisture content.

- Equipment for cooling fishmeal:

The goal is to bring the fishmeal to room temperature and stop it from burning fat from being too hot. An excellent refrigerator that rapidly and effectively cools fishmeal.

- Equipment for vacuum concentration:

By recovering and concentrating the protein solution created during the production process, fish meal production costs may be decreased while advantages are improved.

- Fishmeal deodorization equipment:

Deodorization eliminates the fishmeal production process’s odour and lessens its negative effects on the environment and the air.

Conclusion:

A wide range of healthful elements, such as essential amino acids and minerals like iron and phosphorus, may be found in fishmeal. This meal is a powerhouse that provides many living things with essential nutrients. The processing and source of the basic materials in a fish meal determine its effectiveness. For dinner to be of the highest quality, it must be cooked correctly and with the appropriate ingredients. To ensure the flawless integration of the three main service chains before and after sales, SunRise Eco-protection has committed to providing the necessary technical support and services. To add more value for customers, our after-sales technical team and quick response plan ensure the smooth operation of all links, including design, production, installation, commissioning, personnel training, and after-sales support. We also offer long-term quality tracking service for turnkey livestock and poultry rendering project that has been tried, tested, and approved.

Categories

Recent Posts

-

A guide to Scientists poultry farming on farms: reducing costs, increasing efficiency, and protecting the ecosystem

August 27, 2025 -

Global treatment and sustainable utilization of slaughterhouse waste

August 13, 2025 -

Choosing the right equipment can solve all the problems in animal fat processing

August 1, 2025