Secador de Tambor: An Overview of the Drum Dryer and Its Uses

Secador de Tambor: An Overview of the Drum Dryer and Its Uses

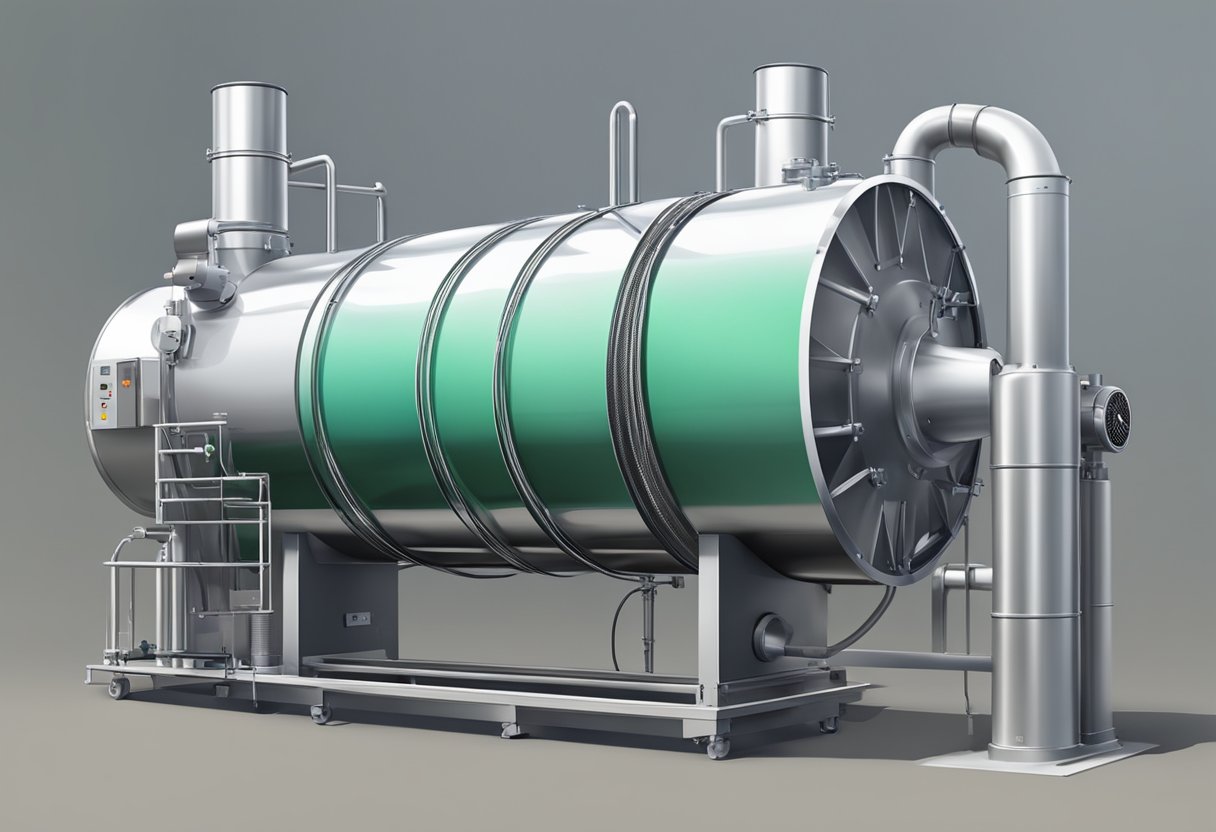

A Secador de Tambor, also known as a drum dryer, is a type of industrial dryer that is commonly used to dry a wide range of materials such as grains, chemicals, minerals, and other bulk solid materials. The dryer consists of a rotating drum that is heated from the inside using steam or hot gases. As the material is fed into the drum, it is dried and then discharged at the other end.

One of the main advantages of using a Secador de Tambor is its ability to handle a wide range of materials with varying moisture contents. The dryer is designed to operate at a low speed, which ensures that the material is evenly dried without being damaged or agglomerated. Additionally, the dryer’s design allows for the material to be continuously fed and discharged, which makes it ideal for large-scale industrial applications.

Despite its many benefits, the Secador de Tambor requires careful operation and maintenance to ensure optimal performance and efficiency. Regular cleaning and inspection of the drum and other components are necessary to prevent buildup and damage. With proper care and attention, a drum dryer can provide reliable and efficient drying for many years.

Overview of Drum Dryers

Drum dryers, also known as rotary dryers, are a type of industrial dryer used to reduce or remove moisture from a material. They are commonly used in the food, chemical, and mineral processing industries, among others.

Drum dryers consist of a large, rotating drum that is heated from the inside. The material to be dried is fed into the drum at one end and is gradually heated as it moves towards the other end. As the material moves through the drum, it is exposed to hot air, which evaporates the moisture and removes it from the material.

One of the advantages of drum dryers is their ability to handle a wide range of materials, including powders, granules, and even sticky or pasty materials. They are also able to dry materials to a very low moisture content, making them ideal for use in applications where low moisture levels are required.

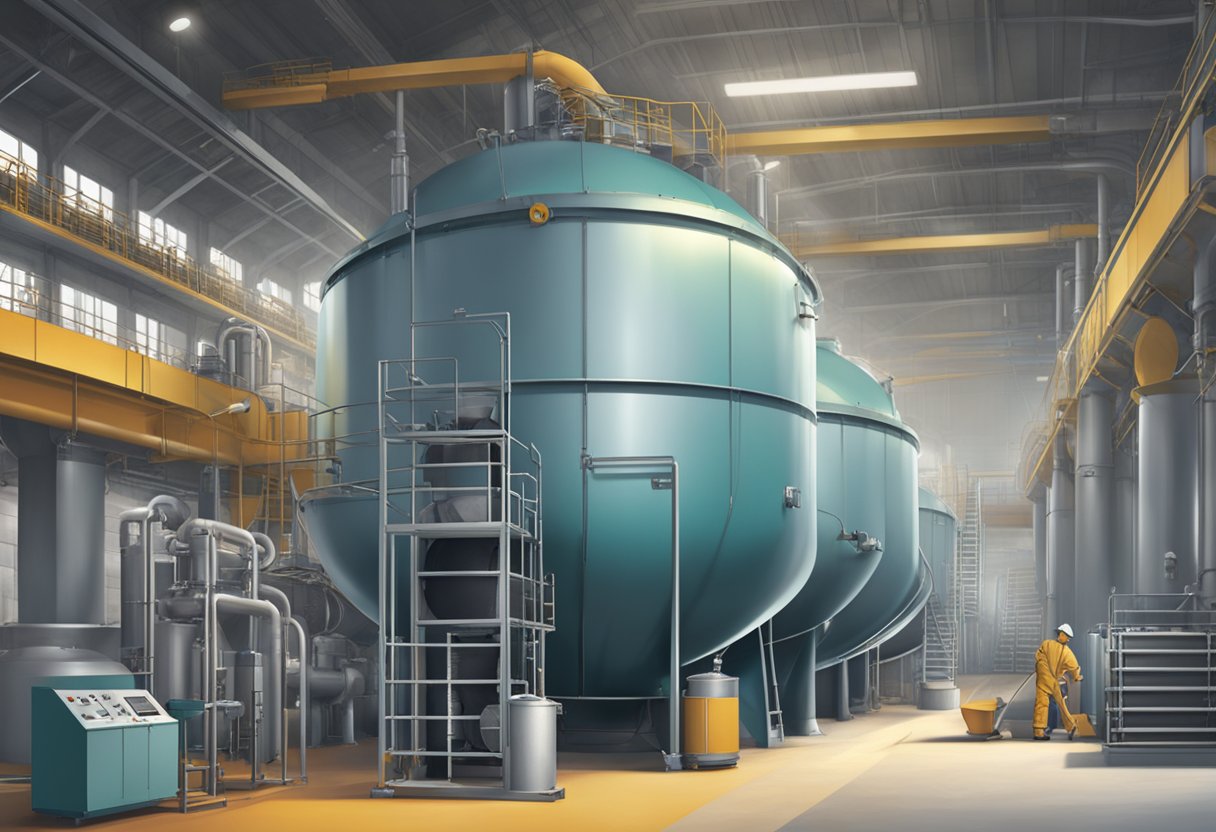

Drum dryers come in a variety of sizes and configurations, with options for direct or indirect heating, and single or multiple drums. They can also be designed to operate under vacuum or at high pressure, depending on the requirements of the application.

Overall, drum dryers are a reliable and efficient way to remove moisture from materials, and are widely used in a variety of industries.

Types of Drum Dryers

Drum dryers are widely used in various industries for drying materials. These dryers work by rotating a drum around its axis and heating it from the inside. The material to be dried is fed into the drum, and as the drum rotates, the material is exposed to hot air, which dries it. There are several types of drum dryers available in the market, some of which are discussed below.

Single Drum

Single drum dryers are the simplest and most commonly used type of drum dryer. As the name suggests, they consist of a single rotating drum, which is heated from the inside. The material to be dried is fed into the drum from one end, and as the drum rotates, it is exposed to hot air, which dries it. Single drum dryers are suitable for drying a wide range of materials, including grains, minerals, and chemicals.

Double Drum

Double drum dryers consist of two drums that rotate in opposite directions. The material to be dried is fed into the space between the two drums, and as the drums rotate, the material is exposed to hot air, which dries it. Double drum dryers are suitable for drying materials that are sensitive to heat and require gentle handling. They are commonly used for drying dairy products, such as milk and cream.

Twin Drum

Twin drum dryers are similar to double drum dryers, but they have two separate drums that rotate in the same direction. The material to be dried is fed into one drum, and as the drum rotates, the material is exposed to hot air, which dries it. The dried material is then transferred to the second drum for further drying. Twin drum dryers are suitable for drying materials that require a longer drying time, such as wood chips and sawdust.

In conclusion, drum dryers are an effective and efficient way to dry materials. The type of drum dryer to be used depends on the material to be dried and the drying requirements. Single drum dryers are suitable for drying a wide range of materials, while double drum and twin drum dryers are suitable for materials that require gentle handling and a longer drying time, respectively.

Working Principle of Drum Dryers

Drying Mechanism

Drum dryers, also known as rotary dryers, are used to dry materials with high moisture content. The drying process involves feeding wet material into the rotating drum, where it comes into contact with hot air. As the drum rotates, the material is lifted and falls back down, continuously exposing it to the hot air. This constant movement and exposure to heat causes the moisture to evaporate from the material, leaving it dry.

The drying mechanism of drum dryers is based on the principle of convection. Hot air is blown into the drum, and as it comes into contact with the wet material, it absorbs the moisture and carries it away. The hot air then exits the drum, and the moisture is removed from the system through a vent.

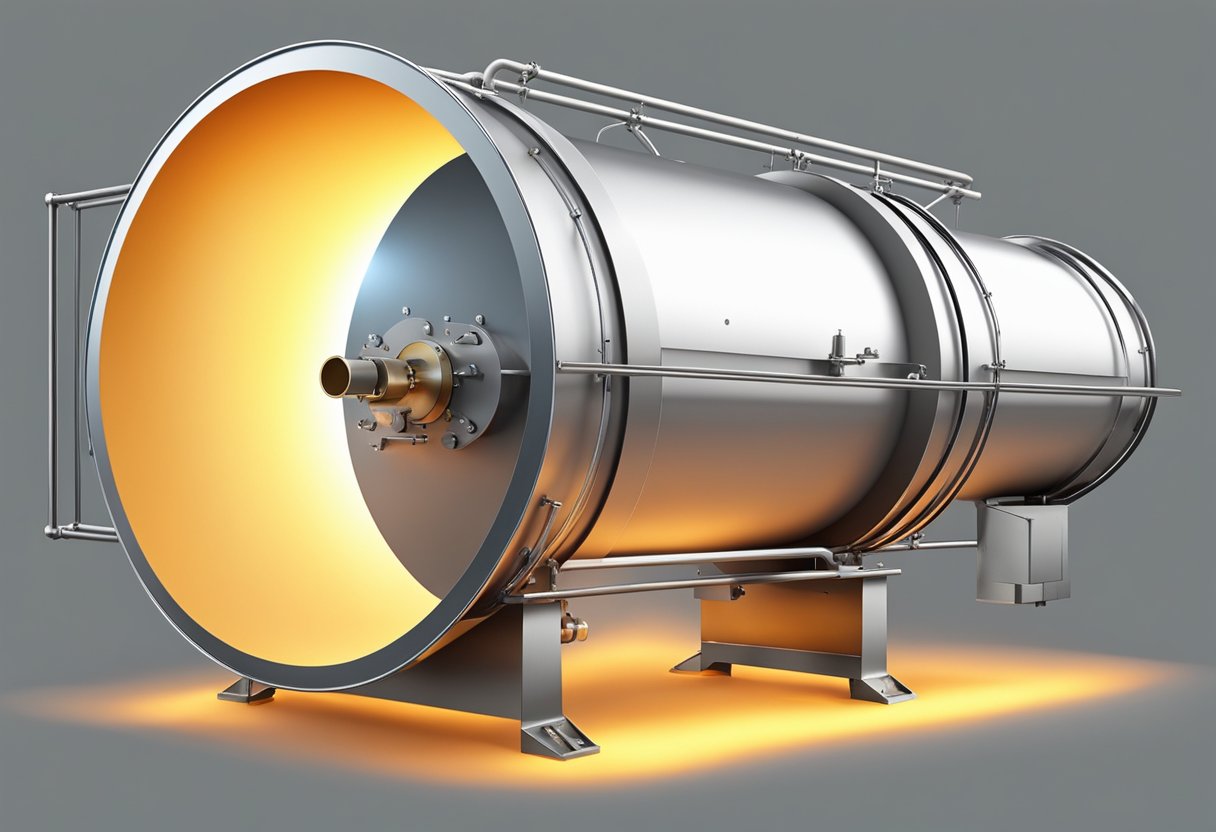

Heat Source

The heat source for drum dryers can be either gas, oil, or electricity. Gas and oil-fired dryers are the most common, as they provide a high heat output and are cost-effective. Electric dryers are less common, as they are more expensive to operate and have a lower heat output.

The heat source is located outside the drum, and the hot air is blown into the drum through a duct. The temperature of the hot air can be controlled to achieve the desired level of drying. As the moisture evaporates from the material, the temperature inside the drum decreases, and the heat source compensates by increasing the temperature of the hot air.

In conclusion, drum dryers are an effective and efficient way to dry materials with high moisture content. Their convection-based drying mechanism and various heat source options make them a versatile choice for a range of industries.

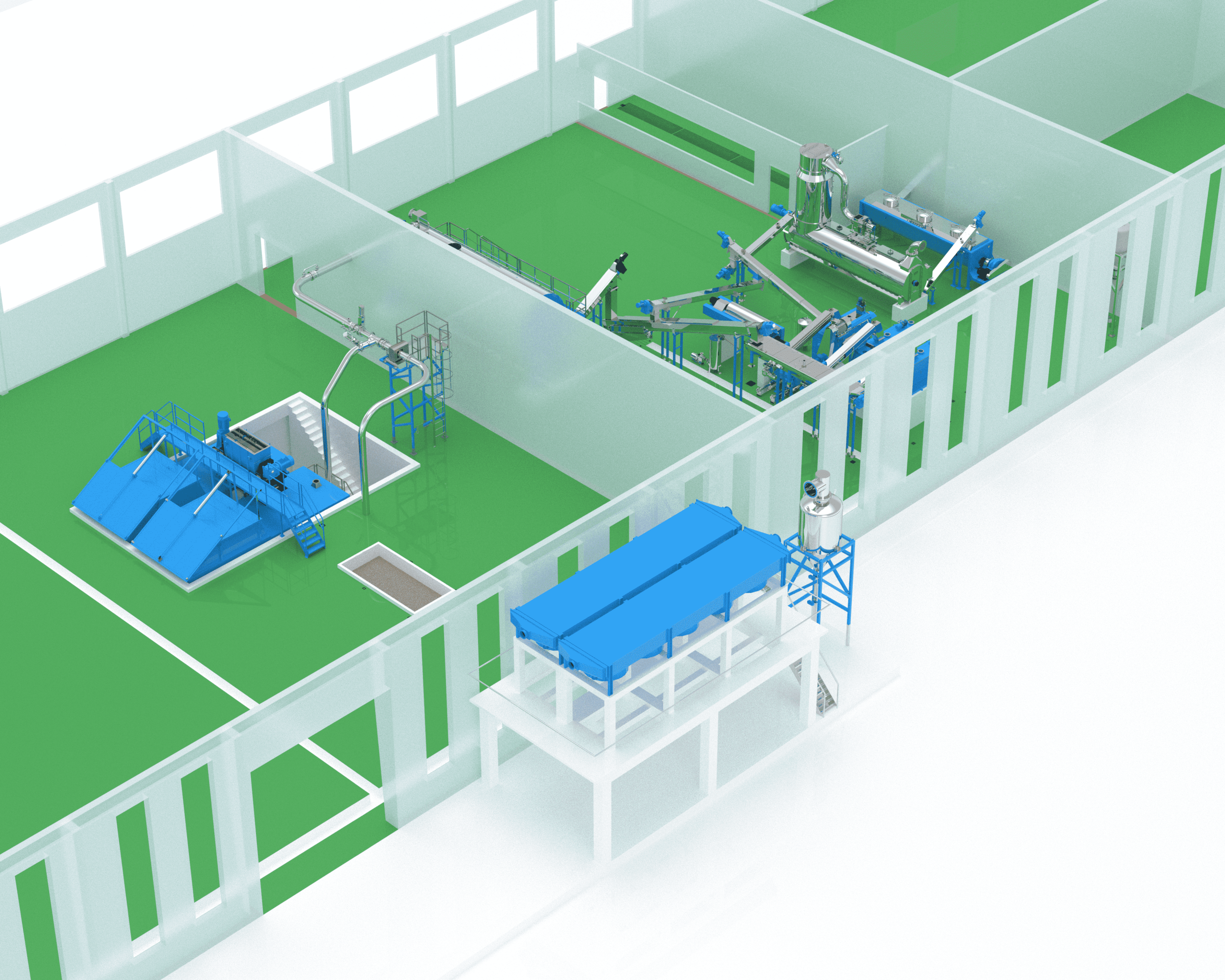

Applications of Drum Dryers

Drum dryers are widely used in various industries due to their versatility and efficiency. Here are some of the most common applications of drum dryers:

Food Industry

Drum dryers are extensively used in the food industry for drying various food products such as fruits, vegetables, dairy products, and cereal grains. The drum dryer’s ability to dry food products quickly and uniformly without damaging the product’s flavor, color, or nutritional value makes it a preferred choice for food processing companies.

In the food industry, drum dryers are used for drying products such as:

- Potato flakes

- Breakfast cereals

- Baby food

- Soup mixes

- Fruit and vegetable powders

Chemical Industry

Drum dryers are widely used in the chemical industry for drying various chemical products such as pigments, resins, and polymers. The drum dryer’s ability to dry chemical products quickly and uniformly without altering their chemical properties makes it a preferred choice for chemical processing companies.

In the chemical industry, drum dryers are used for drying products such as:

- Pigments

- Resins

- Polymers

- Detergents

- Fertilizers

Pharmaceuticals

Drum dryers are also used in the pharmaceutical industry for drying various pharmaceutical products such as antibiotics, vitamins, and herbal extracts. The drum dryer’s ability to dry pharmaceutical products quickly and uniformly without altering their chemical properties makes it a preferred choice for pharmaceutical processing companies.

In the pharmaceutical industry, drum dryers are used for drying products such as:

- Antibiotics

- Vitamins

- Herbal extracts

- Active pharmaceutical ingredients (APIs)

- Excipients

Overall, drum dryers are versatile and efficient drying machines that are widely used in various industries.

Design Features

Material of Construction

The secador de tambor is typically constructed using high-quality materials such as stainless steel, carbon steel, or other alloys. The material of construction is selected based on the specific application and the properties required for the drying process. Stainless steel is commonly used for applications that require resistance to corrosion and high temperatures, while carbon steel is used for applications that require high strength and durability.

Flight Design

The flight design of the secador de tambor plays a critical role in the efficiency and effectiveness of the drying process. The flight design refers to the shape and orientation of the paddles or flights inside the drum. The paddles are strategically placed to lift and tumble the material as it moves through the drum, ensuring that it is evenly exposed to the hot gases and that it dries uniformly.

The flight design can vary depending on the specific application and the characteristics of the material being dried. For example, a steep flight angle is often used for materials that are prone to sticking or clumping together, while a shallow flight angle is used for materials that are more free-flowing.

In summary, the secador de tambor is designed with high-quality materials and carefully engineered flight designs to ensure efficient and effective drying of a wide range of materials.

Efficiency and Energy Considerations

Secador de tambor is known for its high efficiency and energy-saving features. The system is designed to maximize the drying process while minimizing energy consumption. The following are some of the efficiency and energy considerations that make secador de tambor a cost-effective and eco-friendly solution.

Insulation

One of the key features of secador de tambor is its excellent insulation. The drum is made of high-quality materials that provide excellent insulation properties. This means that the heat generated during the drying process is retained within the drum, reducing energy consumption and increasing efficiency.

Heat Recovery

Another important feature of secador de tambor is its heat recovery system. The system captures the heat generated during the drying process and recycles it back into the system. This means that less energy is required to maintain the desired temperature, resulting in significant energy savings.

Variable Speed Drive

Secador de tambor is equipped with a variable speed drive that allows the system to operate at different speeds depending on the requirements of the drying process. This feature ensures that the system operates at maximum efficiency, reducing energy consumption and minimizing operating costs.

Automatic Control System

The automatic control system of secador de tambor ensures that the drying process is optimized for maximum efficiency. The system monitors the temperature and humidity levels within the drum and adjusts the settings accordingly. This means that the system operates at optimal efficiency, reducing energy consumption and maximizing the drying process.

In conclusion, secador de tambor is an efficient and energy-saving solution for drying processes. Its insulation, heat recovery system, variable speed drive, and automatic control system make it a cost-effective and eco-friendly option for businesses looking to reduce their energy consumption and operating costs.

Maintenance and Cleaning

Routine Maintenance

To ensure the smooth operation of the secador de tambor, routine maintenance is necessary. The following tasks should be performed regularly:

- Check the bearings for any signs of wear or damage. Replace them if necessary.

- Lubricate the bearings and other moving parts according to the manufacturer’s instructions.

- Inspect the drum for any signs of damage or wear. Replace it if necessary.

- Check the drive belts for any signs of wear or damage. Replace them if necessary.

- Inspect the electrical connections for any signs of wear or damage. Replace them if necessary.

By performing these routine maintenance tasks, the secador de tambor will operate efficiently and last longer.

Cleaning Procedures

Cleaning the secador de tambor is also important to ensure its proper operation. The following cleaning procedures should be performed regularly:

- Remove any debris or buildup from the drum and the exhaust system.

- Clean the lint filter and replace it if necessary.

- Clean the interior of the drum with a damp cloth and mild detergent. Avoid using harsh chemicals or abrasive materials that can damage the drum.

- Clean the exterior of the secador de tambor with a damp cloth and mild detergent. Avoid using water on electrical components.

By following these cleaning procedures, the secador de tambor will operate efficiently and safely.

Safety and Operational Guidelines

When using a secador de tambor, it is important to follow certain safety and operational guidelines to ensure the equipment functions properly and to prevent any accidents. Here are some important guidelines to keep in mind:

- Always wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and ear protection when operating the secador de tambor.

- Before starting the equipment, make sure that the drum is free from any debris or foreign objects that may cause damage or affect the drying process.

- Ensure that the secador de tambor is properly grounded to prevent any electrical hazards.

- Do not overload the equipment with materials as this may cause the drum to malfunction or cause the material to overheat.

- Regularly inspect and maintain the equipment to ensure that it is functioning properly. This includes checking for any signs of wear and tear, lubricating moving parts, and replacing any damaged or worn out components.

- Always follow the manufacturer’s instructions and guidelines for operating the secador de tambor. Failure to do so may result in equipment damage or personal injury.

By following these safety and operational guidelines, you can ensure that your secador de tambor operates safely and efficiently, providing you with the best possible results for your drying needs.

Advancements in Drum Dryer Technology

Drum dryers have been used for decades to dry various materials, such as food, chemicals, and minerals. In recent years, advancements in technology have led to improvements in the efficiency and effectiveness of drum dryers.

One major advancement is the use of computer controls to monitor and adjust the temperature and airflow within the drum. This allows for precise control of the drying process, resulting in a more consistent and higher quality product. Additionally, computer controls can detect and alert operators to any potential issues, such as overheating or blockages, before they become major problems.

Another advancement is the use of advanced materials for the drum itself. Traditional drum dryers were made of carbon steel, which can corrode and wear down over time. However, newer models often use stainless steel or other corrosion-resistant materials, which can extend the lifespan of the drum and reduce maintenance costs.

In addition, some drum dryers now feature integrated heat recovery systems, which capture and reuse waste heat from the drying process. This not only reduces energy consumption and operating costs, but also helps to reduce the overall environmental impact of the drying process.

Overall, these advancements in drum dryer technology have made them more efficient, reliable, and environmentally friendly. As technology continues to evolve, it is likely that we will see even more improvements in the years to come.

Market Trends and Demand

The market for secador de tambor, or drum dryer, has been steadily growing in recent years. This is due to the increasing demand for efficient and cost-effective drying solutions in various industries such as food, chemical, and pharmaceutical.

One of the major trends in the market is the adoption of advanced technologies in drum dryers. Manufacturers are incorporating features such as automated controls, real-time monitoring, and energy-efficient systems to enhance the performance and reduce operational costs. This has resulted in a significant increase in the demand for such high-tech drum dryers.

Another trend is the increasing demand for customized drum dryers. Customers are looking for tailor-made solutions that meet their specific requirements in terms of capacity, drying time, and energy efficiency. Manufacturers are responding to this demand by offering a wide range of customization options and flexible designs.

The demand for drum dryers is expected to continue growing in the coming years, driven by the increasing need for efficient and sustainable drying solutions. Manufacturers are expected to focus on developing innovative technologies and expanding their product portfolios to cater to the evolving needs of the market.

Environmental Impact and Sustainability

The use of secador de tambor in industrial processes has a significant impact on the environment. The equipment consumes a considerable amount of energy, which contributes to the emission of greenhouse gases. However, the use of this equipment can also have some positive environmental impacts, especially when compared to other drying technologies.

One of the advantages of using secador de tambor is that it can reduce the emission of pollutants to the environment. This equipment operates in a closed system, which prevents the release of dust and other harmful particles into the air. Additionally, the use of secador de tambor can help reduce the amount of waste generated in industrial processes, as it allows for the recovery and reuse of materials that would otherwise be discarded.

To ensure the sustainability of the use of secador de tambor, it is essential to consider factors such as energy efficiency and the use of renewable energy sources. The equipment should be designed and operated to minimize energy consumption and reduce the emission of greenhouse gases. Additionally, the use of renewable energy sources such as solar, wind, or hydroelectric power can help reduce the environmental impact of secador de tambor.

In conclusion, the use of secador de tambor in industrial processes has both positive and negative environmental impacts. To ensure the sustainability of its use, it is essential to consider factors such as energy efficiency, the use of renewable energy sources, and the reduction of waste generation.

Categories

Recent Posts

-

Global treatment and sustainable utilization of slaughterhouse waste

September 1, 2025 -

A guide to Scientists poultry farming on farms: reducing costs, increasing efficiency, and protecting the ecosystem

September 1, 2025 -

Choosing the right equipment can solve all the problems in animal fat processing

August 1, 2025