slaughtered chickens to treasure

From slaughtered chickens to treasure: Sunrise slaughter waste equipment leads the way to high-value utilization

With the large-scale development of modern agriculture and slaughtering industry, the scientific treatment of slaughtering waste has become a key issue related to sustainable development. If the animal carcass waste such as chicken bones, chicken frames, blood, viscera, feathers and production and processing waste such as grease and oil residue generated by slaughtering chickens are not properly disposed, it will cause multiple environmental crises: the foul smell released by the rotting waste continues to disturb the lives of residents; Direct discharge of wastewater leads to eutrophication of water bodies and destroys the balance of aquatic ecosystems;pathogens leaking from landfills will pollute soil resources in the long term. Faced with severe challenges, Sunrise relies on innovative technology to create efficient and durable slaughter waste equipment. Through resource conversion, it can extract high-value raw materials such as oil and protein while eradicating pollution,creating a win-win situation for the industry in terms of ecological environmental protection and economic benefits,and promoting the transformation of the chicken slaughtering industry towards a green and low-carbon future.

Relying on the world’s leading deep processing technology, Sunrise efficiently transforms the slaughter waste of slaughtered chickens and provides global customers with a complete solution based on the production of meat and bone meal. It transforms the “scraps” produced by slaughtering chickens into nutritious and widely used high-quality animal meat and bone meal/chicken meal, leading a new trend of resource recycling.

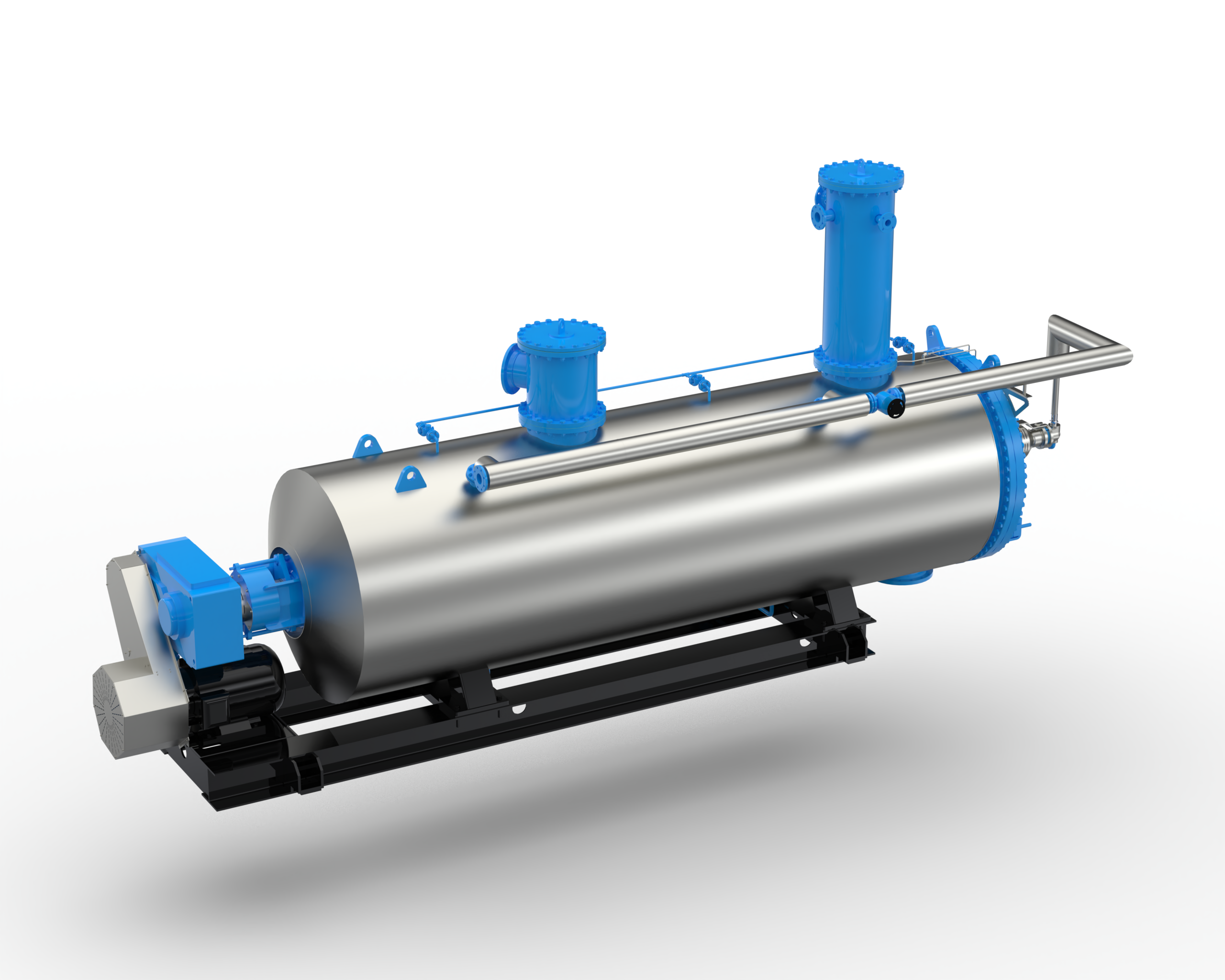

If you have a batch of raw materials such as chicken bones, chicken frames, feathers, etc.from slaughtered chickens that need to be processed, Sunrise will tailor the best solution for you. The principle of slaughter waste is to sterilize the slaughter waste by introducing a high-temperature circulating heat source into the interlayer in a closed high-pressure sandwich container. The hot steam does not directly contact the slaughter waste. This process uses high temperature and high pressure. The center temperature of the treated material is ≥140℃,the pressure is ≥0.5MPa (absolute pressure), the time is ≥4h, and the pressure is maintained for 30 minutes.The VOCs (volatile organic gases) generated during the treatment process are treated in multiple stages and finally meet the emission standards.

Under Sunrise’s core technology, the nutrients in the raw materials are effectively released and stably retained, producing high-quality meat and bone meal/chicken meal products with pure flavor and easy digestion and absorption. At present, Sunrise meat and bone meal/chicken meal production lines have provided customized services for many customers around the world:

1.Feed field: As a cost-effective source of animal protein and minerals, Sunrise products can effectively replace traditional fish meal and ordinary meat and bone meal. Especially when added to poultry, pig and aquatic feed, it can significantly reduce formula costs and improve feed conversion rate.

2.Pet food: Products made from fresh raw materials of slaughtered chickens are ideal raw materials for high-end pet dry food, wet food and snacks due to their natural meaty aroma, high protein, rich collagen and good palatability.

3.Organic fertilizer: Rich in organic matter and various mineral elements, it is a high-quality base material for making high-efficiency organic fertilizer or soil conditioner.

Sunrise’s intelligent slaughter waste production line has a flexible processing capacity (0.5-100 tons/day), which is particularly suitable for processing by-products generated by large-scale slaughter of chickens. For ultra-large-scale projects (more than 100 tons/day), Sunrise provides in-depth customized services. The whole set of equipment has a high degree of integration and significantly lower energy consumption than traditional processes. In the successful case of a large-scale slaughter chicken processing group in Shandong, China, the meat and bone meal workshop built by Sunrise achieved the goal of zero by-product waste and created huge additional income every year.

Sunrise provides a full-cycle service based on slaughter waste, from process design, core equipment manufacturing and installation, commissioning and operation training.The professional technical team responds 24/7 to ensure the stable and efficient operation of the customer’s production line.For customers who plan to invest in the treatment of slaughter chicken by-products, Sunrise recommends a phased solution.Taking the standard processing line as an example, relying on Sunrise EPC general contracting services, It usually takes 6-8 months to complete the construction and put into production.Sunrise provides personalized design and optimizes the solution to maximize the return on investment based on your slaughter chicken processing scale, site conditions and production capacity requirements.

If you are dealing with a large amount of slaughtered chicken by-products and looking for a high-value solution,Sunrise’s advanced meat and bone meal production line is your ideal choice.Sunrise is committed to providing the best slaughtered chicken waste solution to help you maximize the value of slaughtered chicken resources.Choosing Sunrise, you will get excellent technology, reliable equipment and highly competitive overall value.