What Is A Rendering Plant?

What Is A Rendering Plant?

What is a rendering plant?

A rendering plant is a facility that converts meat by-products or carcasses into usable products such as tallow, chicken fat, grease, meat, and bone meal. Rendering plants are typically used to dispose of animal carcasses, but they also serve an important role in the recycling industry.

Rendering plants also process animal fats and oils for use in many applications, including food production, soap making, and cosmetics production. Rendering animal products are used in both the commercial and household sectors.

Commercial rendering plants

These facilities process animal byproducts from slaughterhouses, meat-packing plants, dairies, and other sources. They can also process restaurant grease and used cooking oil. The rendered materials are edible or inedible and then sold as ingredients to manufacturers who use them to make soap, candles, and other products.

Household rendering plants

Household rendering plants recycle kitchen fats, oils, and grease into biodiesel fuel. These facilities are often operated by local government agencies or private companies hired by the government to collect grease from restaurants or homeowners who have installed collection containers in their homes.

The various types of rendering plants

Rendering plants are available in different types, and each of these has its own unique features. The following are some of the types of independent renderers that are used today:

1. Mechanical rendering plant

This is the most common type of rendering plant. It is used to process raw materials such as bones, animal fat, and meat scraps into high-quality protein meals and fat. The main equipment in mechanical rendering plants is a large steam cooker, a continuous screw conveyor, a vacuum filter, and various types of crushers.

2. Boiler rendering plant

The boiler system is mainly composed of boilers, steam generators or heat exchangers, and other auxiliary equipment such as feed pumps, blowers, and air coolers. The boiler system can be divided into two types according to the heating medium – liquid fuel boilers and coal-fired boilers.

Coal-fired boilers are widely used by small-scale enterprises because they are economical and easy to operate. While oil-fired boilers are more popular among large-scale enterprises due to their better thermal efficiency and higher heating capacity.

3. Dry rendering plant

This type of dry rendering plant involves the use of mechanical devices such as grates, conveyors, shredders, hammer mills, etc. Which can efficiently reduce bones into small pieces through abrasion after crushing them.

The products of rendering plants

In order to better study what is a rendering plant, first understand the products of a rendering plant. Rendering plants are facilities that produce animal byproducts. The byproducts are used as ingredients in many industries which include the food, pharmaceutical, and cosmetic industries. The following take Sunrise rendering plant projects as an example to explain.

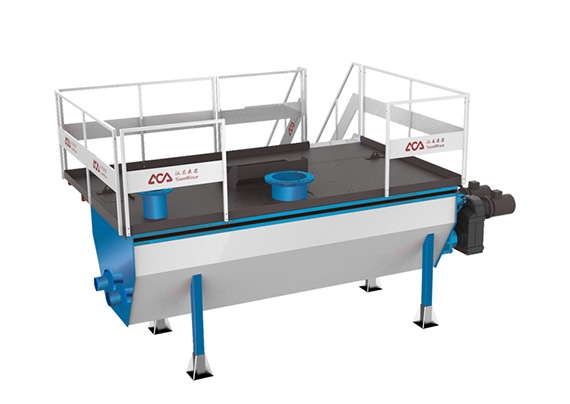

1. Batch Cooker

Jiangsu Sunrise batch cooker is designed for various functions to process meat by-products. A Batch cooker has a variety of manufacturing standards according to the needs of different processing plants and is one of the most important equipment for a rendering plamt.

Batch cookers are used to sterilize raw materials through a combination of heat and pressure. The raw materials are cooked under pressure to remove moisture from them before they are ground into a meal. The cooked material is then allowed to cool down in a condenser vessel where it solidifies into a cake. In the case of poultry by-products, the material is then further dried by circulating hot air through it.

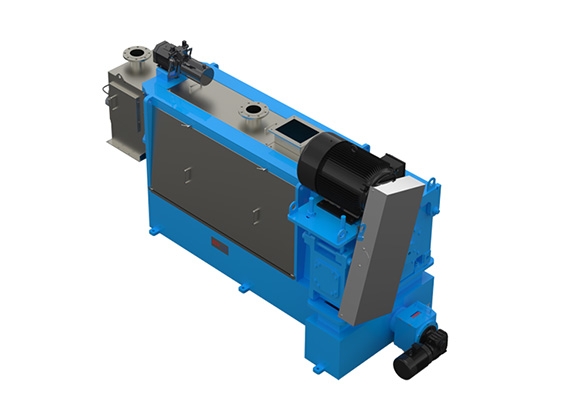

2. Fat Screw Press

Jiangsu SunRise fat screw press machine is the next step after animal waste is processed by Batch Cooker, and the fat in it is squeezed through the screw machine continuously. The machine uses screw-pressing technology and can press the material at a high speed. The materials are heated before they enter the screw-pressing chamber.

The screw press has two chambers: one is used to heat up the material, while the other can be used to press out the oil after it has been heated up. The two chambers are separated by a plate that rotates in order to push the material through them and squeeze out as much oil as possible. The oil will then be collected in another container so that it can be filtered and refined later on if necessary.

3. Cyclone Dust Collector

The cyclone dust collector is used to collect trace material in gas during pressure relief and drying. It can be used in many different industries, including the rendering industry. The cyclone dust collector is made up of two main parts: a centrifugal fan and a conical separator. The centrifugal fan provides the force needed to separate particulate matter from the gas stream.

This is accomplished by creating an enclosed vortex of air that spins at high speeds and creates centrifugal force. It causes particulate matter to be thrown out of the system into a conical separator where it can be collected for later disposal or recycling.

4.Buffer Bin

The Buffer Bin is used to temporarily store the materials discharged from the cooking drying tank. And it conveys the materials to the filter screen screw conveyor through the screw conveyor at the bottom of the receiving bin.

Filter Screen Screw Conveyor is mainly used for conveying materials from buffer bins to raw meal bins, as well as for transporting slop from raw meal bins to tanks for storage with solid wastes or for disposal.

How does a rendering plant work?

Through the simple description above, believe you should have a basic understanding of what is a rendering plant, then continue to learn about how it works.

Rendering is the process of cooking raw materials for animal feed, fertilizer, or other products. It is an industrial process that takes a wide variety of raw materials and converts them into a more usable product. Rendered products are often used in pet food, fertilizer, and biodiesel production.

The rendering process can also be used to dispose of dead animals that would otherwise be buried or burned. However, it is most commonly used for animal byproducts from slaughterhouses and meat packing plants that include bones, blood, hair, hooves, and horns.

The rendering process begins with the removal of any non-edible parts like skin, hair, and sinew from the carcass. The remaining fat tissue is melted down at high temperatures until it turns into a tallow. It is then filtered through cheesecloth to remove any remaining solid material. The resulting liquid fat is then cooled and solidified into blocks known as tallow candles.

The remaining bone material goes through a similar process but instead of being filtered through cheesecloth. It goes through a hammermill so that all bone particles are broken down into smaller pieces before they can be ground into bone meal powder.

The benefits of a rendering plant

The rendering process also produces a number of edible products that can be sold or used in your food industry, including fertilizer, soap, glue, paint, and even plastic pellets.

The benefits of a rendering plant are very numerous, and it is important to take some time to understand them. This will allow you to make the right decision when it comes to this type of business. Here are some of the advantages of owning a rendering plant:

1.Profit Potential

One of the main reasons why many people choose to own their own rendering plant is because they believe there is lots of money that may be billions of pounds to be made from it. While this may not always be true, there certainly is potential for profit if you run your business properly and invest in the right equipment at the right time.

The cost of operating a rendering plant is very low compared to other methods of producing animal fat such as slaughtering animals yourself or purchasing it from supermarkets. This makes it affordable for small businesses that cannot afford to buy expensive equipment or pay high wages to workers with special skills.

2.Environmental Benefits

Another reason why people want their own rendering plant is because they want to do something good for the environment. Owning a rendering plant means that you don’t have to bury or burn dead animals anymore.

Unlike slaughtering animals yourself, there is no pollution when you use a rendering plant. Because all wastes are processed into various products such as tallow and bones which are sold for profit.

3.Increased Product Variety

Another benefit of operating a rendering plant is that it gives you access to an increased variety of finished products compared with buying them from another company or manufacturer.

Conclusion

A rendering plant is a kind of equipment for producing cooking oil and other similar products by means of thermal treatment. It is widely used in many industries such as food processing, pharmaceuticals, chemicals, and others. In addition, the rendering plant can also be used for producing animal fat filling for soap making.

If you want to purchase a rendering plant, you can choose the company SunRise to help. Because they have been dealing with this kind of equipment for many years and they know all about them very well. They can provide different types of rendering plants according to your needs including small-scale ones with low cost but good quality or large-scale ones.