Benefits Of Sunrise Continuous Hydrolyser For Animal Rendering Plants

Benefits Of Sunrise Continuous Hydrolyser For Animal Rendering Plants

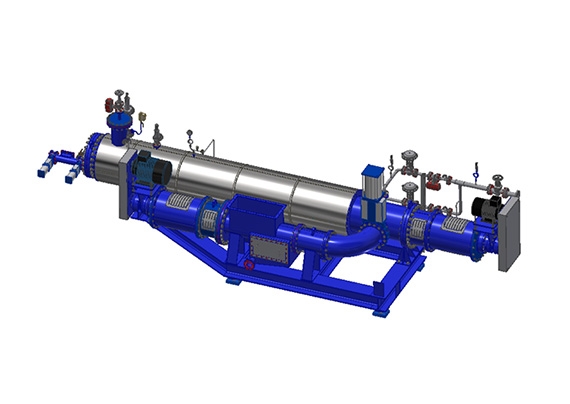

About The Continuous Hydrolyser

When dealing with large volumes of waste, it is essential to ensure that all chemicals are removed. Continuous hydrolysers are the most advanced and easy-to-operate units available. The hydrolysers are specifically designed for the processing of feathers, hog hair.

The continuous hydrolyser uses a gentle heat process that does not use any chemicals or acids. This means that there is no risk of contamination from toxic fumes or spills. The continuous hydrolysers also produce a very high-quality product that can be used as an organic fertilizer or soil conditioner.

Hydrolyzed feather powder is high-pressure curing, clean and undecomposed poultry feathers without additives. The pressure curing method can partially hydrolyze the protein and destroy the keratin bond, and it is the keratin bond that forms the special structure of the feather fiber. The feather meal produced in this way has good fluidity and palatability, and is easily digested by animals.

Features Of Continuous Hydrolyser

Continuous hydrolysers are the most advanced and easy-to-operate units available. The hydrolysers are specifically designed for the processing of feathers, hog hair, and animal offal.

The Features Of The Continuous Hydrolyser Include:

- 1) Large Capacity: The capacity of the unit can be up to 5 ton per hour.

- 2) Simplicity Of Operation: The unit is easy to operate and requires minimal supervision.

- 3) High-Quality Protein Output: The hydrolyser produces a high-quality protein with good amino acid balance and low ash content compared to other methods of protein recovery.

- 4) Easy Cleaning And Maintenance: The open design of the unit allows it to be cleaned and maintained easily while in operation or when idle which reduces downtime and increases productivity.

The System Has Many Advantages Over Existing Technologies:

- 1. Continuous automatic production saves manpower and increases output.

- 2. Special spindle to ensure efficient and uniform hydrolysis.

- 3. The total average steam consumption is low, reducing operating costs

Benefits Of Sunrise Continuous Hydrolyser

Sunrise Continuous Hydrolyser is designed to be a cost-effective alternative to batch hydrolysis systems. The continuous system delivers the same high-quality product in a fraction of the time, making it ideal for larger operations or those with fluctuating demand.

1. Improved Recovery of Fat and Protein

The Sunrise Continuous Hydrolyser improves the recovery of fat and protein compared to conventional hydrolyzers using a two-phase process. The result is a higher quality product with reduced foul odor and taste.

2. Faster Production Rates

The Sunrise Continuous Hydrolyser allows you to produce more hydrolysate in less time than any other method on the market. The hydrolyser can produce up to 5t/h at a full production rate. This means the hydrolysis process can be completed in a fraction of the time compared with batch processing.

The use of continuous hydrolysis results in higher yields with less waste than batch systems. This is because all the processes take place inside one closed system, which minimizes loss of moisture from evaporation as well as reduces the amount of water required for each batch process. The result is that you get more protein at a lower cost per kg than batch systems.

3. Better, More Powerful Flow Control

The Sunrise Continuous Hydrolyser has a unique flow control system that provides more powerful flow control than other hydrolysers in its class. The Sunrise Continuous Hydrolyser can be easily adapted to your process needs by simply changing the flow control valve.

4. Exceptional Protein Recovery

Sunrise Continuous Hydrolyser is the most advanced continuous hydrolysis system in the world. It offers superior protein recovery, precise temperature control, and process safety.

5. Greater Efficiency With Animal Feed Protein

The use of continuous hydrolysis is becoming increasingly popular in the animal feed industry. The main reason for this is that the process is more efficient than batch hydrolysis. This means that more protein can be extracted from the same amount of feed, which can lead to cost savings.

This is because it uses more sophisticated technology, which allows for a more controlled environment and better monitoring. In addition, there are no batching issues associated with this process, so the end product will always be consistent in quality.

6. Fewer Maintenance Costs

Since all the processes take place inside one closed system, there is no risk of contamination from outside sources like dirt or dust particles entering the chamber during production. This also makes cleaning easier since there are no gaps between components where dirt can hide and grow bacteria.

Applications Of Continuous Hydrolyser

The Continuous Hydrolyser is a continuous process for producing hydrolysed protein from protein-rich materials, such as fish meals and meat and bone meals. The process uses intense heat and pressure to break down complex proteins without changing the molecular structure of individual amino acids.

The Continuous Hydrolyser is an ideal solution for food manufacturers who want to create hydrolyzed protein products without the need for expensive downstream processing steps. It can also be used to produce specialty amino acids for use in pharmaceuticals or animal feed supplements.

A continuous hydrolyser can be used to produce feather meal or feather-meal powder from feathers and poultry offal. Feather meal contains 40% protein, which is high quality protein. This protein can be used as a raw material for poultry feed or as a partial replacement of soybean meal in broiler diets. The main use of feather meal is as an animal feed additive, but it also has value as a soil fertilizer and soil conditioner when applied to soils with low organic matter content.

Sunrise Continuous Hydrolyser VS Other Continuous Hydrolyser

The Sunrise Continuous Hydrolyser is a continuous hydrolyser that can process up to 5 tons per hour. This means it can be used for small and large-scale applications. The Sunrise Continuous Hydrolyser is designed to be easy to use, maintain, and clean. Its compact size allows it to fit in small spaces and take up less room on your production floor.

The Sunrise Continuous Hydrolyser is the most advanced hydrolyser on the market. The Sunrise Continuous Hydrolyser combines all of the benefits of a high-quality hydrolyzer with a number of additional features that make it truly unique.

The Sunrise Continuous Hydrolyser has been designed to be easy to use and maintain. You will never have to wait for your system to warm up or cool down before using it because there are no moving parts inside the unit which could break or leak oil onto your product. This makes it simple and safe to operate, even if you are new to this type of technology.

Why Choose Sunrise For Your Continuous Hydrolyser Manufacturer?

Sunrise is a leading manufacturer of continuous hydrolysers for the rendering plant industry. Sunrise has many years’ experience in industrial plant design and has treatment and process automation solutions for the the recycling of animal protein and fat, kitchen waste treatment, and sludge reduction treatment.

Sunrise’s team is committed to customer service and satisfaction. Sunrise understands that your business needs are different from other businesses, so Sunrise works with each customer individually to ensure that they get exactly what they need. Whether you’re looking for an upgrade or simply need parts replaced, Sunrise is here for you.

If you are looking for a continuous hydrolyser manufacturer, then Sunrise should be your first choice. Here are just some of the reasons why:

- – Sunrise offers a range of models that can handle different volumes and pressures of your product with ease. Your hydrolyser will be fully customised to suit the needs of your process without compromising on quality or safety.

- – Sunrise offers complete turnkey solutions which include everything from design through to installation, commissioning and training so that you can focus on running your business while Sunrise takes care of your equipment needs.

- – Sunrise’s continuous hydrolysers are made using high quality materials that ensure they last for years without requiring any maintenance or repairs during their lifetime.

Conclusion

The hydrolyzer is a revolutionary piece of equipment for the rendering process, as it does away with the need for chemicals and other additives. It also makes processing sludge safer for both workers and the environment, which has a substantial cost-reduction benefit.

The positive impact that a hydrolyser can provide cannot be overstated. The countless benefits of this machine should not be overlooked or forgotten, as it is certainly a valuable asset for any plant to have. As a rendering plant owner, you should weigh the cost of this machine against the potential benefits. Only then will you be able to make an educated decision on whether or not to purchase a continuous hydrolyser for your plant.

Finally, thank you for reading our article on the benefits of a continuous hydrolyser for animal rendering plants. Sunrise hopes that it was helpful for you and clears up how the hydrolyzer equipment works. If you are interested in lower energy consumption, waste disposal, or reducing your costs, please feel free to contact Sunrise.