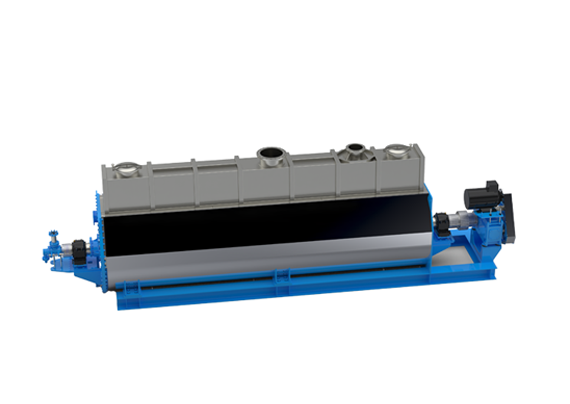

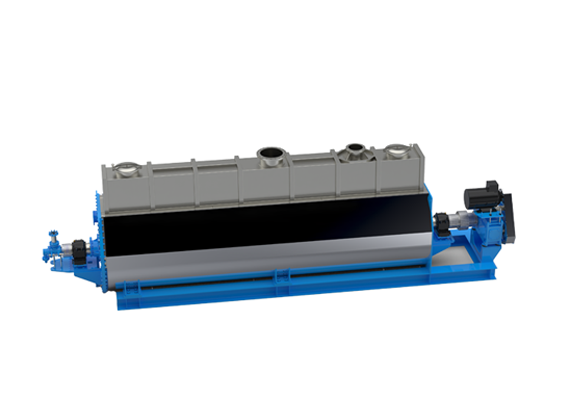

Description

Continuous Cooker Application

Jiangsu sunrise continuous cooker is one of the most efficient systems for continuous cooking of any kind of animal by-product. This method of processing animal by-products is suitable for large production capacities. It ensures homogeneity in the final products and achieves very low ratio of energy per kg of material processed.

Continuous cookers are industrial kitchen equipment used for mass food production such as soups, sauces, stews and jams.It operates by heating and mixing ingredients continuously, reducing cooking time and ensuring consistent quality of the final product.

Applications of continuous cookers include:

- Food processing industries specialize in mass producing ready-to-eat meals, sauces, soups and stews for ready consumption.

- Confectionery industries: for production of chocolate, candy, and other sweets.

- Beverage industries: for production of syrups, juices, and concentrates.

- Pharmaceutical industries: for production of ointments, creams, and gels.

- Chemical industries: Producing adhesives, resins and other chemical products.

Continuous cookers are built for large-volume production and come equipped with features such as temperature controls, mixing mechanisms, and automated discharge systems to make them efficient and effective industrial use.

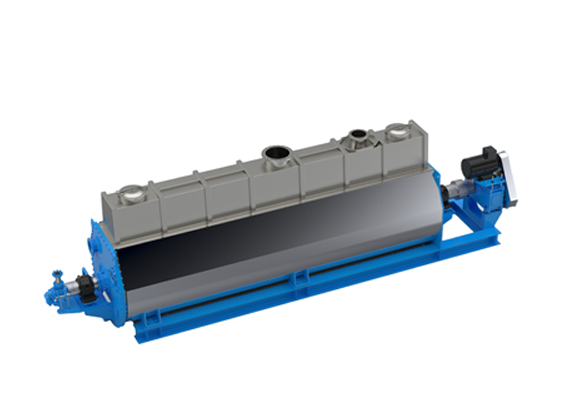

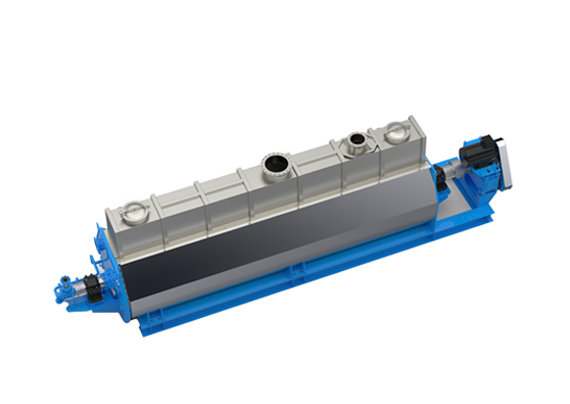

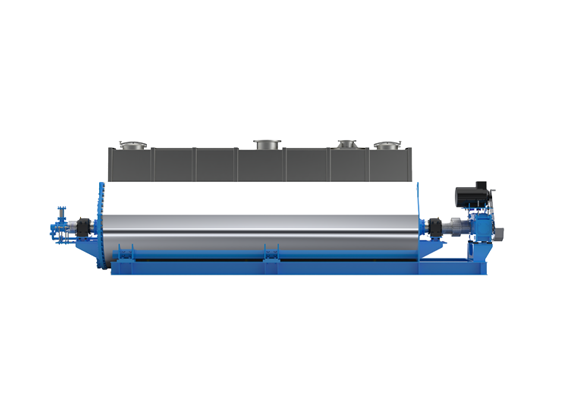

Design characteristics

1. A rotating steam heated multi-tubular shaft inside the body of the LXZZ cooker provides a large heating surface.

2. The U-shaped body of the continuous cooker has a multi-tubular long life shaft heated by steam (maximum 10 bar).

3. The cooking temperature is adjustable according to the requirements of the process and type of raw material.

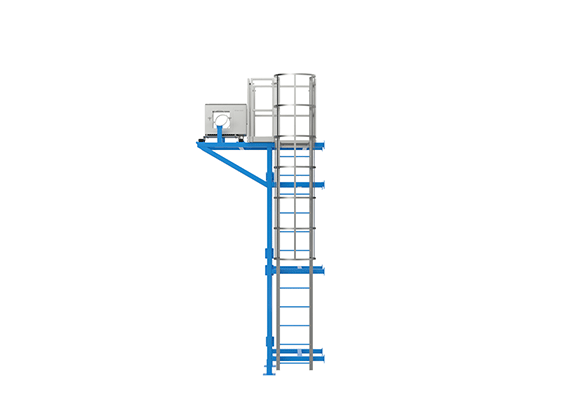

4. Evaporated water from the material is ducted through a cyclone(XFFL) where entrained particles are captured and returned into the cooker while the vapors continue onto subsequent condensing or other vapor treatment systems.

5. The greaves (dehydrated mixture of proteins and fats) are extracted from the cooker continuously and separated into proteins and fat by subsequent processing stages.

6. Jiangsu Sunrise continuous cooker complies with GB national standards and each machine is produced, inspected and tested in accordance with GB pressure vessel standard and regulations.

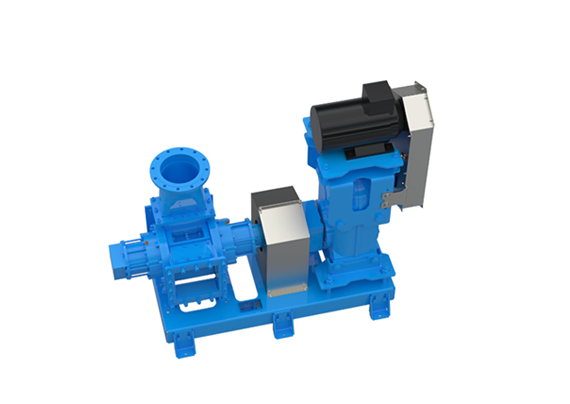

7. Collocation equipment: cyclone, oil drainer, one unit pipeline, weight system, discharging screw.

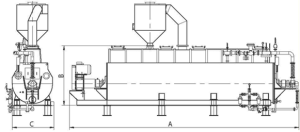

Technical parameter

| Model | Power (kW) |

Weight (kg) |

Evaporation capacity (kg/h*) |

Size (mm) | ||

| A | B | C | ||||

| LXZZ06 | 37 | 19000 | 2000 | 8000 | 2800 | 1600 |

| LXZZ09 | 55 | 25000 | 3000 | 10400 | 3100 | 1900 |

| LXZZ12 | 75 | 32000 | 4000 | 12200 | 3100 | 2100 |

| LXZZ18 | 90 | 48000 | 6000 | 13200 | 3400 | 2300 |

| LXZZ24 | 132 | 60000 | 8000 | 13600 | 4150 | 2700 |

what is Continuous Cooker

Continuous cookers are built for large-volume production and come equipped with features such as temperature controls, mixing mechanisms, and automated discharge systems to make them efficient and effective industrial use.It operates by continuously feeding ingredients into the cooker, heating and mixing them, and then discharging the finished product. The continuous cooker offers the benefit of decreasing cooking duration while maintaining uniform quality during large-scale production. Its application spans across the food processing, confectionery, beverage, pharmaceutical, and chemical sectors.

Continuous Cooker FQA

- What is a continuous cooker?

- Continuous cookers are kitchen machines used to quickly prepare large volumes of food at once by continuously cooking it as it passes through.

- What are the benefits?

- Increased efficiency, improved quality and consistency, reduced labor and increased food safety.

- What types of food can be cooked?

- Foods like sauces, soups, stews, stocks, and purees can be cooked in a continuous cooker.

- How does work?

- It works by heating the food as it passes through a series of heating zones or chambers in a controlled and consistent manner.

- How is the temperature and cooking time controlled in a continuous cooker?

- Temperature and cooking times are controlled using thermostats, timers, sensors and conveyor belt speeds as a combination.

- Is a continuous cooker easy to clean and maintain?

- Yes, most continuous cookers are designed with ease of cleaning and maintenance in mind and can be disassembled for easy cleaning.

- Can a continuous cooker be used for both cooking and cooling the food?

- Yes, some continuous cookers have the capability to switch between heating and cooling modes.

- What are the common applications ?

- The common applications of a continuous cooker are in the food and beverage industry, commercial kitchens, and industrial food processing plants.