Description

Application

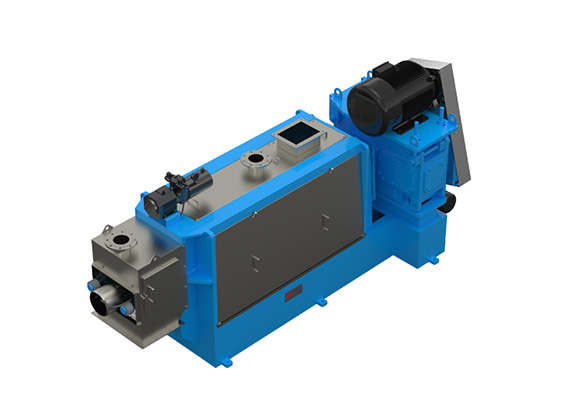

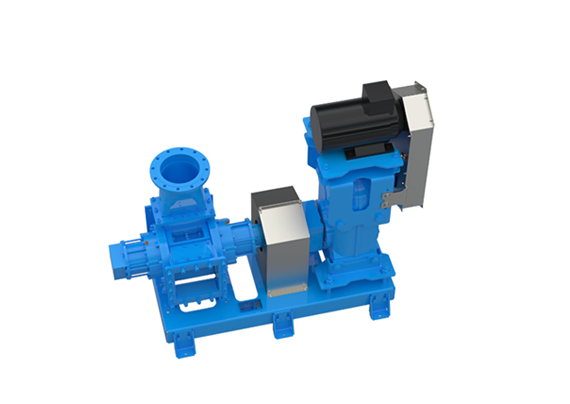

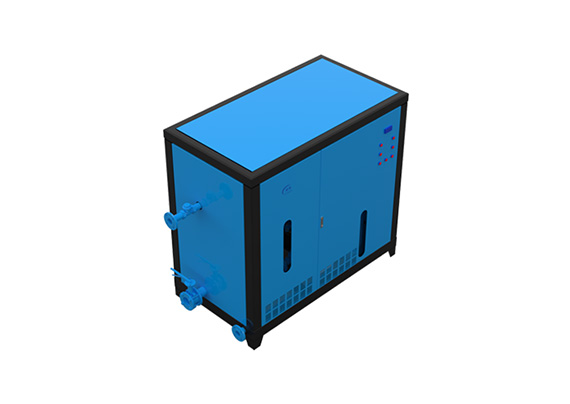

The Fat Screw Press, a cutting-edge mechanical device, serves a pivotal role in various industries by effectively separating liquids from solids in a highly efficient manner. This innovative technology brings with it a multitude of advantages that revolutionize the process of liquid-solid separation.

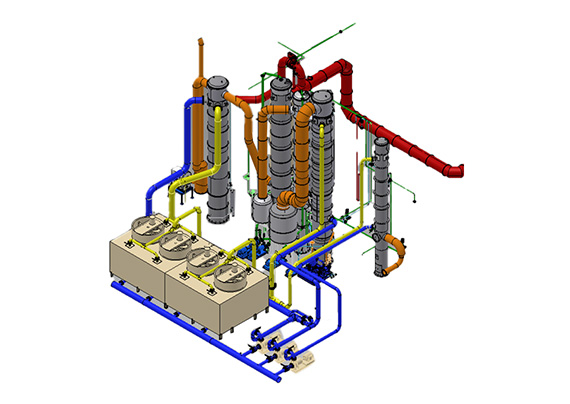

At its core, it employs a unique screw mechanism to exert controlled pressure on the material, facilitating the extraction of liquids from solids. Industries involved in wastewater treatment, food processing, and oil extraction find significant benefits from this process.

In conclusion, the Fat Screw Press stands as a remarkable innovation, transforming the way liquid-solid separation is carried out across industries. Its efficiency, adaptability, and low maintenance needs make it a valuable asset for businesses seeking improved processes and enhanced productivity.