Fish Meal Plant Machine

What is Fish meal Processing Machinery?

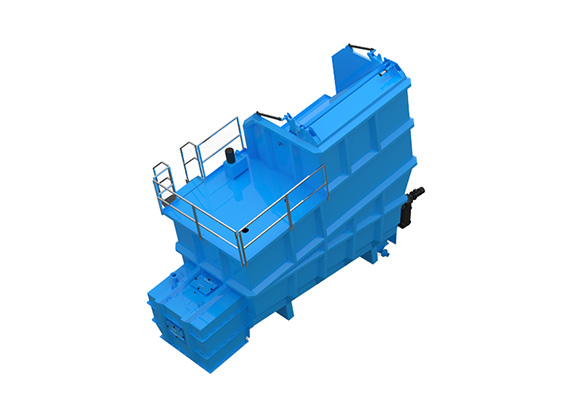

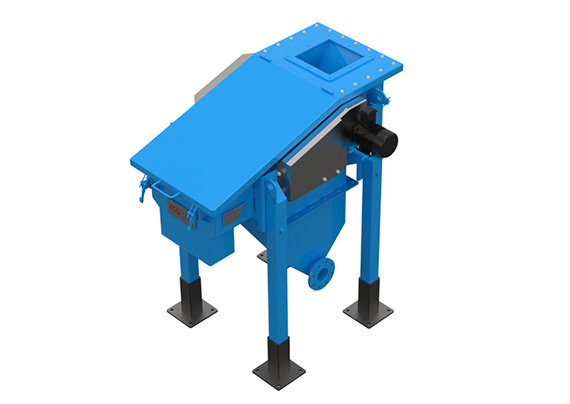

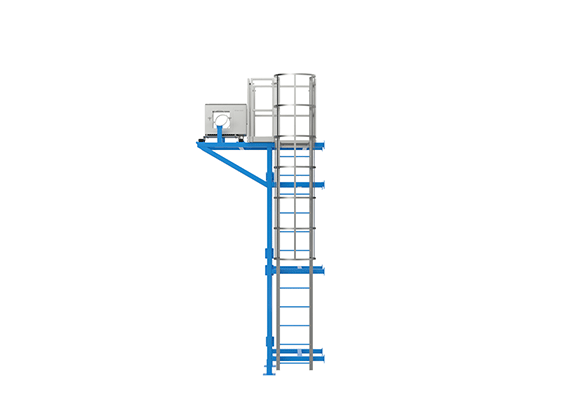

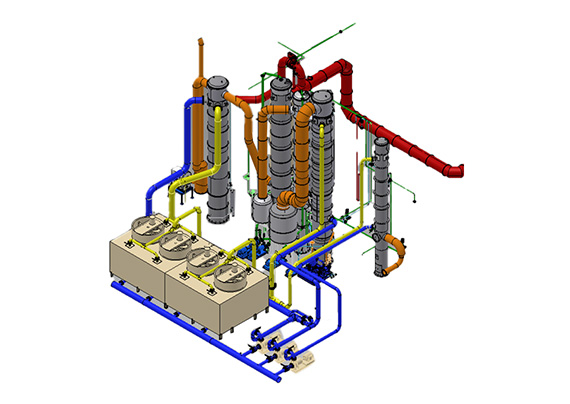

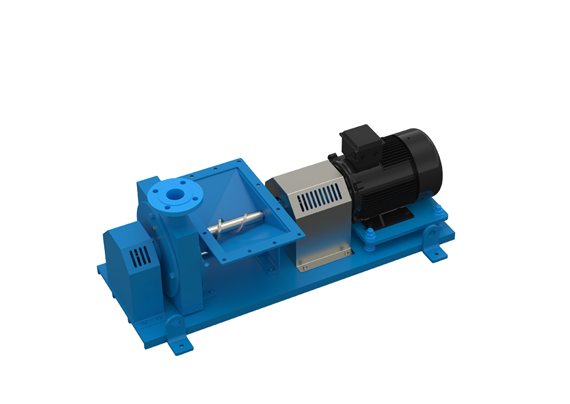

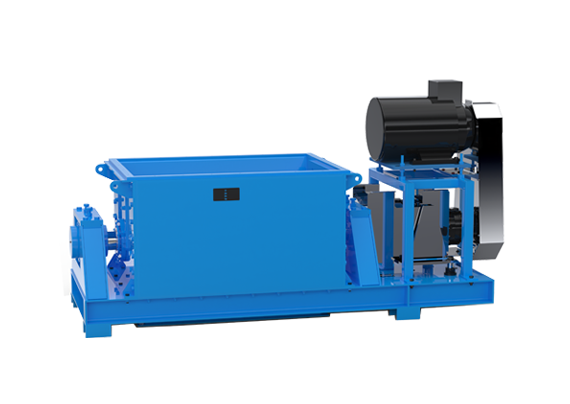

Fish meal processing machinery refers to a specialized set of equipment designed to process raw fish materials into fish meal, a high-protein animal feed ingredient. This machinery transforms fish raw materials into high-value fish meal and fish oil through a series of steps, with the core focus on efficient separation, drying, and environmentally friendly processing. With technological advancements, modern fish meal equipment emphasizes energy efficiency, environmental protection, automation, and comprehensive resource utilization. The selection of such machinery depends on factors such as the type of raw material (e.g., whole fish or fish by-products), production scale, and environmental requirements.

How Does a Fish Meal Production Line Work?

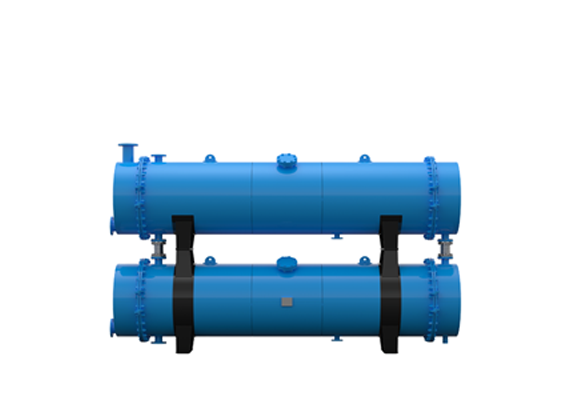

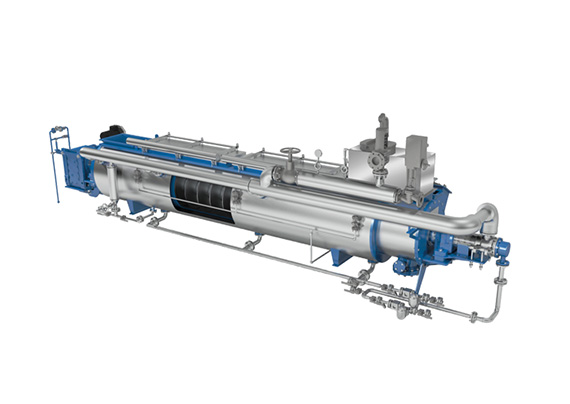

A fish meal production line converts fish raw materials into high-value fish meal and fish oil through a core process involving high-temperature sterilization → mechanical pressing → efficient drying → resource separation, while prioritizing environmental protection and energy efficiency. The key technical aspects include:

– Balancing high-temperature sterilization with protein nutrition retention;

– Improving oil-water separation efficiency;

– Controlling energy consumption and product quality during drying.

With technological progress, fish meal production is evolving toward automation, low energy consumption, and high added-value to meet the feed industry’s demand for sustainable raw materials.

Workflow Overview:

Raw material processing → High-temperature cooking → Pressing and separation → Drying and dehydration → Crushing and screening → Fish oil extraction → Cooling and packaging

Applications of Fish meal and Fish Oil:

fish meal and fish oil are the core products of fish processing, primarily used in feed, food, pharmaceuticals, and industrial applications. fish meal, as an animal feed ingredient with high protein (60-72%) and amino acid content, is widely used in aquaculture (e.g., fish and shrimp feed) and livestock feed (e.g., for pigs and poultry), providing essential nutrients and promoting growth. Its by-products can also be processed into organic or biofertilizers. Fish oil, rich in Omega-3 fatty acids (EPA and DHA), serves not only as a feed additive to enhance animal health but can also be refined for human health supplements (e.g., fish oil capsules), pharmaceuticals (e.g., adjunctive treatment for cardiovascular diseases), and industrial uses (e.g., biodiesel feedstock). Through technologies such as protein extraction from wastewater, exhaust gas purification, and waste heat recovery, the production process achieves resource recycling, combining economic value with environmental benefits. This makes it a key step in the transformation of the aquatic product processing industry toward high added-value and sustainable development.

FAQ

What is a Fish Rendering Plant?

A Fish Rendering Plant is an industrial facility specifically designed to process fish raw materials (e.g., whole fish, fish offal, or fish processing by-products) into fish meal and fish oil through high-temperature cooking, pressing, drying, and other processes. Its core function is to separate proteins, fats, and moisture from fish via physical and chemical treatments, producing high-value animal feed and industrial raw materials while ensuring efficient resource utilization and waste reduction.

How Are Your Equipment Transported and Installed?

Our large-scale equipment can be transported via sea or land, while smaller equipment can be shipped by air. We provide customized installation services for equipment and production lines, offering tailored solutions based on customer needs. Our professional technical team will be dispatched to the site to guide installation, commissioning, and production start-up, with customers only covering travel and labor costs. Alternatively, we offer free remote video-guided installation services, providing real-time support for setup, operational training, and troubleshooting to ensure rapid equipment deployment.

Does Your Equipment Come with a Warranty?

Our manufactured equipment comes with a one-year warranty.

The following scenarios are not covered under warranty:

– Damage caused by improper operation, unauthorized modifications, or intentional misuse;

– Failures resulting from force majeure (e.g., earthquakes, floods) or non-standard operating conditions (e.g., overloading).