Meat Bone Meal Machine

What is Meat and Bone Meal Processing Machinery?

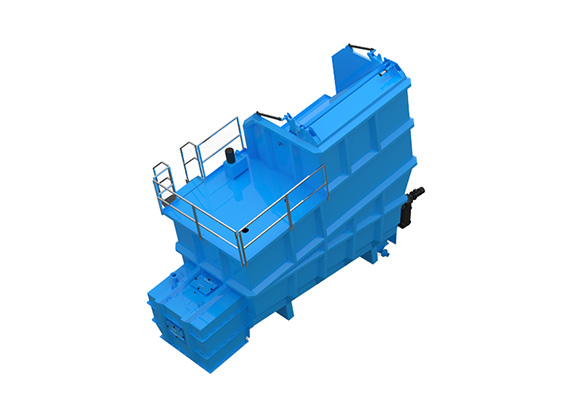

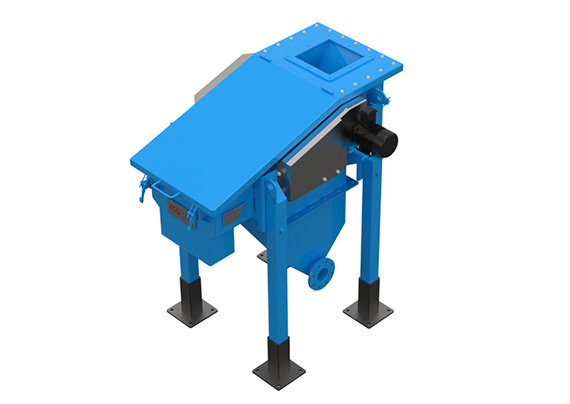

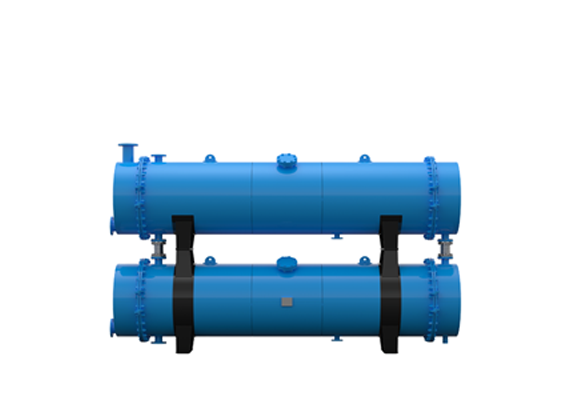

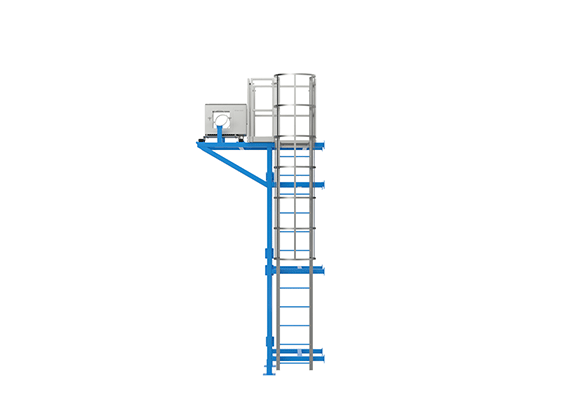

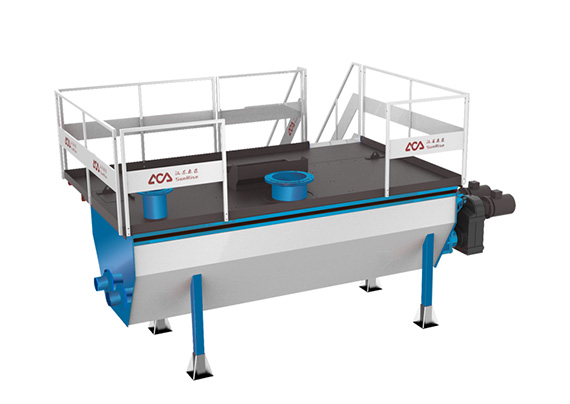

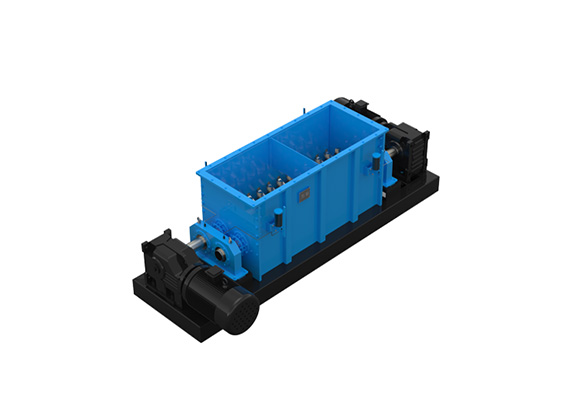

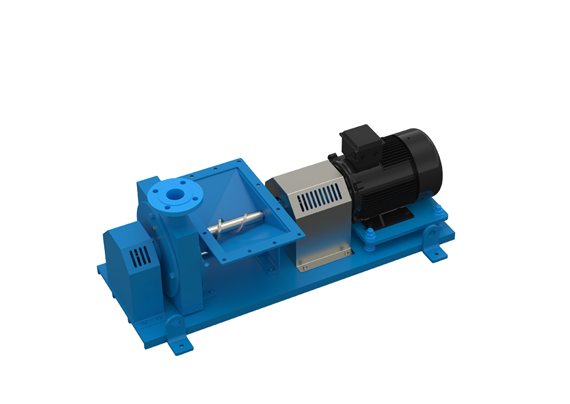

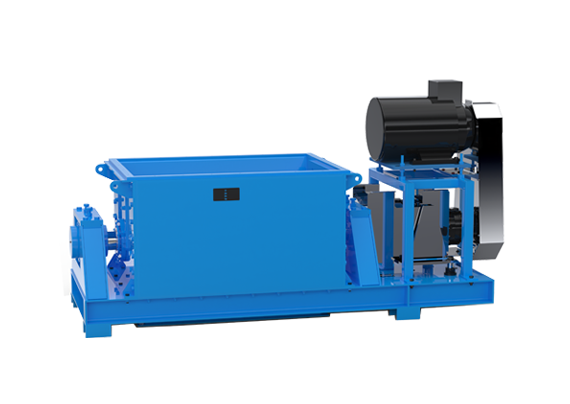

Meat and bone meal (MBM) processing machinery refers to specialized equipment designed to transform animal byproducts from slaughter (such as bones, offal, fat, and meat trimmings) into meat and bone meal—a high-protein, mineral-rich animal feed ingredient. The core processes include crushing, high-temperature sterilization, degreasing, drying, and grinding, ensuring safe raw material treatment, nutrient extraction, and efficient resource utilization. Below are the key equipment components and their functions:

How Does a Meat and Bone Meal Production Line Work?

A meat and bone meal (MBM) production line is an industrial process that converts animal slaughter byproducts (e.g., bones, offal, fat, and meat trimmings) into high-protein feed ingredients or organic fertilizers. Through three core stages—high-temperature sterilization → pressing and degreasing → drying and grinding—the production line transforms animal byproducts into safe and usable protein resources, achieving both efficient resource utilization and biosafety.

Workflow Overview:

Raw material pre-treatment → Cooking → Drying → Fat pressing → Grinding → Final product packaging

Applications of Meat and Bone Meal:

The primary application of meat and bone meal is as a low-cost protein and mineral source in livestock and poultry feed, while also enabling resource recovery from slaughter waste through agricultural fertilizers and industrial uses.

– Animal Feed:

– Livestock & Poultry Feed: Added at 3-5% to provide calcium, phosphorus, and protein (crude protein content: 50-55%).

– Aquafeed: Partially replaces fish meal to reduce costs (requires attention to amino acid balance).

– Organic Fertilizer:

– Serves as a nitrogen-phosphorus-potassium (NPK) compound fertilizer, improving soil structure.

– Industrial Raw Material:

– Used in biodiesel production (utilizing fat content) and adhesive manufacturing (bone glue extraction).

FAQ

What is a Meat and Bone Meal Rendering Plant?

A Meat and Bone Meal Rendering Plant is an industrial facility dedicated to processing animal slaughter byproducts (e.g., bones, offal, meat trimmings, and fat) into meat and bone meal (MBM) and animal fat through high-temperature sterilization, degreasing, and drying. Its core objectives are biosafe treatment, efficient resource utilization, and waste reduction, ultimately producing high-value feed ingredients or industrial raw materials.

How Are Your Equipment Transported and Installed?

Our large-scale equipment can be transported via sea or land, while smaller equipment can be shipped by air. We provide customized installation services for equipment and production lines, offering tailored solutions based on customer needs. Our professional technical team will be dispatched to the site to guide installation, commissioning, and production start-up, with customers only covering travel and labor costs. Alternatively, we offer free remote video-guided installation services, providing real-time support for setup, operational training, and troubleshooting to ensure rapid equipment deployment.

Does Your Equipment Come with a Warranty?

Our manufactured equipment comes with a one-year warranty.

The following scenarios are not covered under warranty:

– Damage caused by improper operation, unauthorized modifications, or intentional misuse;

– Failures resulting from force majeure (e.g., earthquakes, floods) or non-standard operating conditions (e.g., overloading).