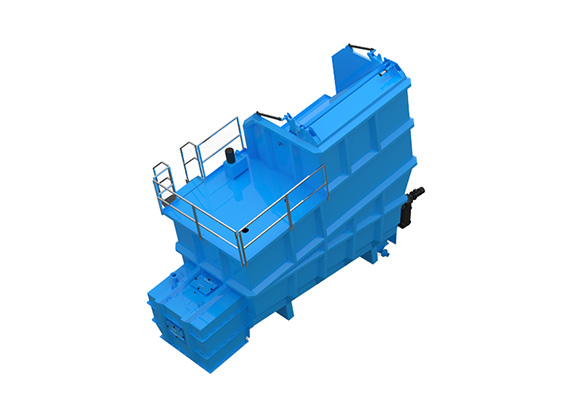

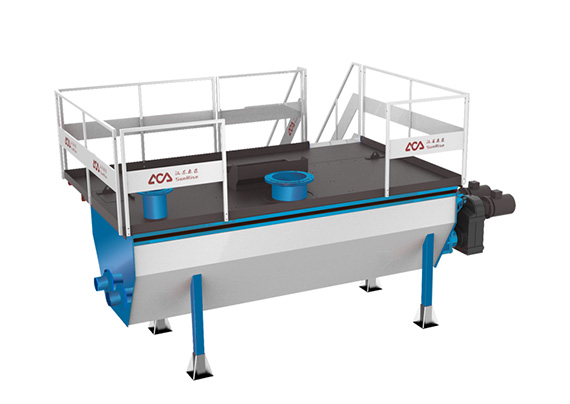

Rendering Plant Machine

What is Rendering Plant Machinery?

Rendering plant machinery refers to industrial equipment systems designed to process animal byproducts from slaughterhouses, fisheries, and food processing (such as bones, offal, fat, meat trimmings, and fish waste) into high-value products like meat and bone meal, fish meal, and animal fats. Its core objectives are waste valorization, production of feed ingredients/biofuels/industrial materials, and environmental protection.

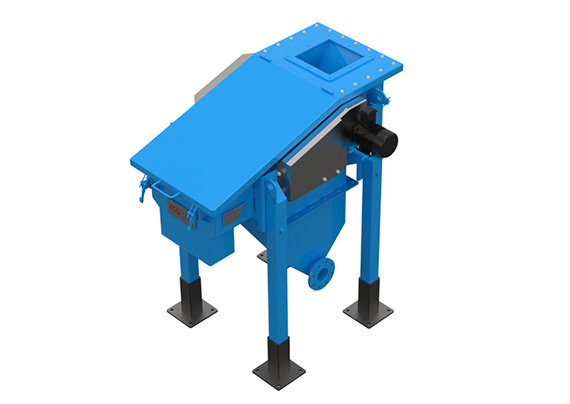

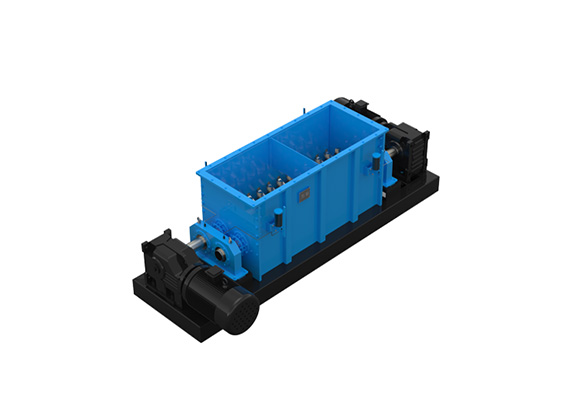

How Does Rendering Plant Machinery Work?

Rendering plant machinery transforms inedible animal byproducts (bones, offal, fat, blood, feathers, etc.) into value-added products (meat and bone meal, animal fats, protein feed) through an integrated industrial process. The system prioritizes sterilization safety, resource recovery, and pollution control, utilizing high-temperature treatment, pressure cooking, and mechanical separation technologies to achieve both waste detoxification and resource conversion.

Workflow Overview:

- Raw material pretreatment

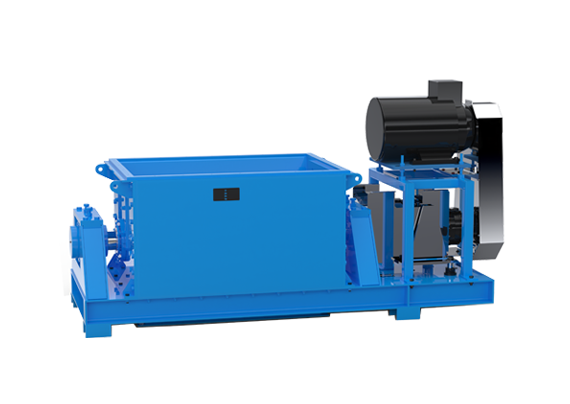

- Cooking/sterilization

- Drying

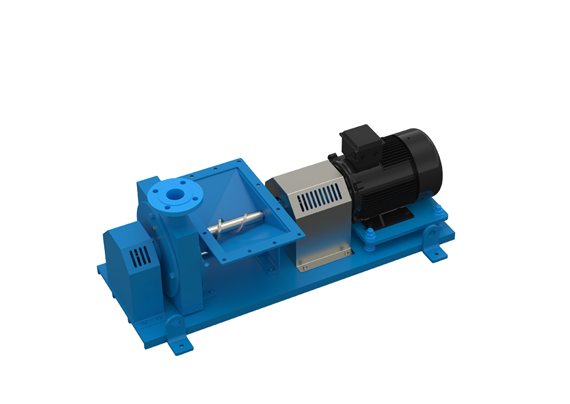

- Fat pressing/extraction

- Grinding

- Final product packaging

Product Applications:

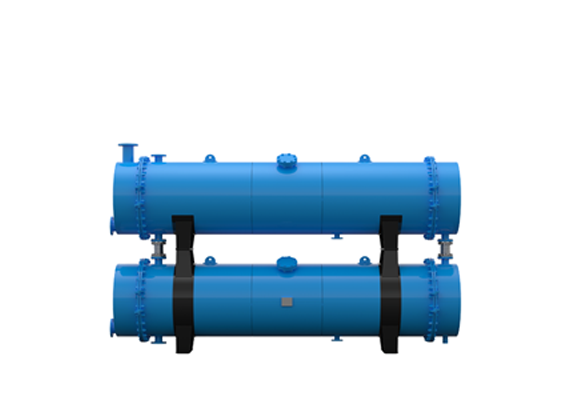

Rendering plant machinery converts slaughter waste into:

– Meat and bone meal: High-protein feed (50-55% crude protein) and organic fertilizer

– Animal fats: Raw material for biodiesel and cosmetics

– Specialty meals: Blood/feather meal for feed protein

– Co-products: Biogas (energy) and liquid feed proteins

These outputs serve:

✔ Feed industry (replacing fishmeal/soybean meal)

✔ Agriculture (soil amendments)

✔ Industrial uses (biofuels, adhesives)

✔ Emerging applications (collagen extraction)

The process enables circular economy benefits by:

- Reducing landfill pollution

- Cutting livestock production costs

- Producing renewable biofuels

Future advancements focus on high-value product development and smart manufacturing integration.

FAQ

What is a Rendering Plant?

A rendering plant is an industrial facility that processes inedible animal tissues (offal, bones, fat, blood, fish waste, etc.) from slaughterhouses, fisheries, and food processors into value-added products. Through core processes including thermal sterilization, fat separation, and drying, it converts waste into:

- Feed ingredients (meat and bone meal, fish meal)

- Bioenergy (biodiesel)

- Industrial materials (bone glue)

The plant achieves dual objectives of resource circularity and pollution mitigation while supporting sustainable development in multiple industries.

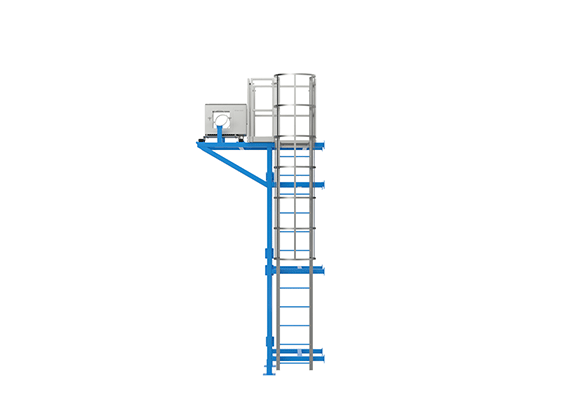

How Are Your Equipment Transported and Installed?

Our large-scale equipment can be transported via sea or land, while smaller equipment can be shipped by air. We provide customized installation services for equipment and production lines, offering tailored solutions based on customer needs. Our professional technical team will be dispatched to the site to guide installation, commissioning, and production start-up, with customers only covering travel and labor costs. Alternatively, we offer free remote video-guided installation services, providing real-time support for setup, operational training, and troubleshooting to ensure rapid equipment deployment.

Does Your Equipment Come with a Warranty?

Our manufactured equipment comes with a one-year warranty.

The following scenarios are not covered under warranty:

– Damage caused by improper operation, unauthorized modifications, or intentional misuse;

– Failures resulting from force majeure (e.g., earthquakes, floods) or non-standard operating conditions (e.g., overloading).