What is a rendering plant? Understanding the Process and its Importance

What is a rendering plant? Understanding the Process and its Importance

What is a rendering plant?

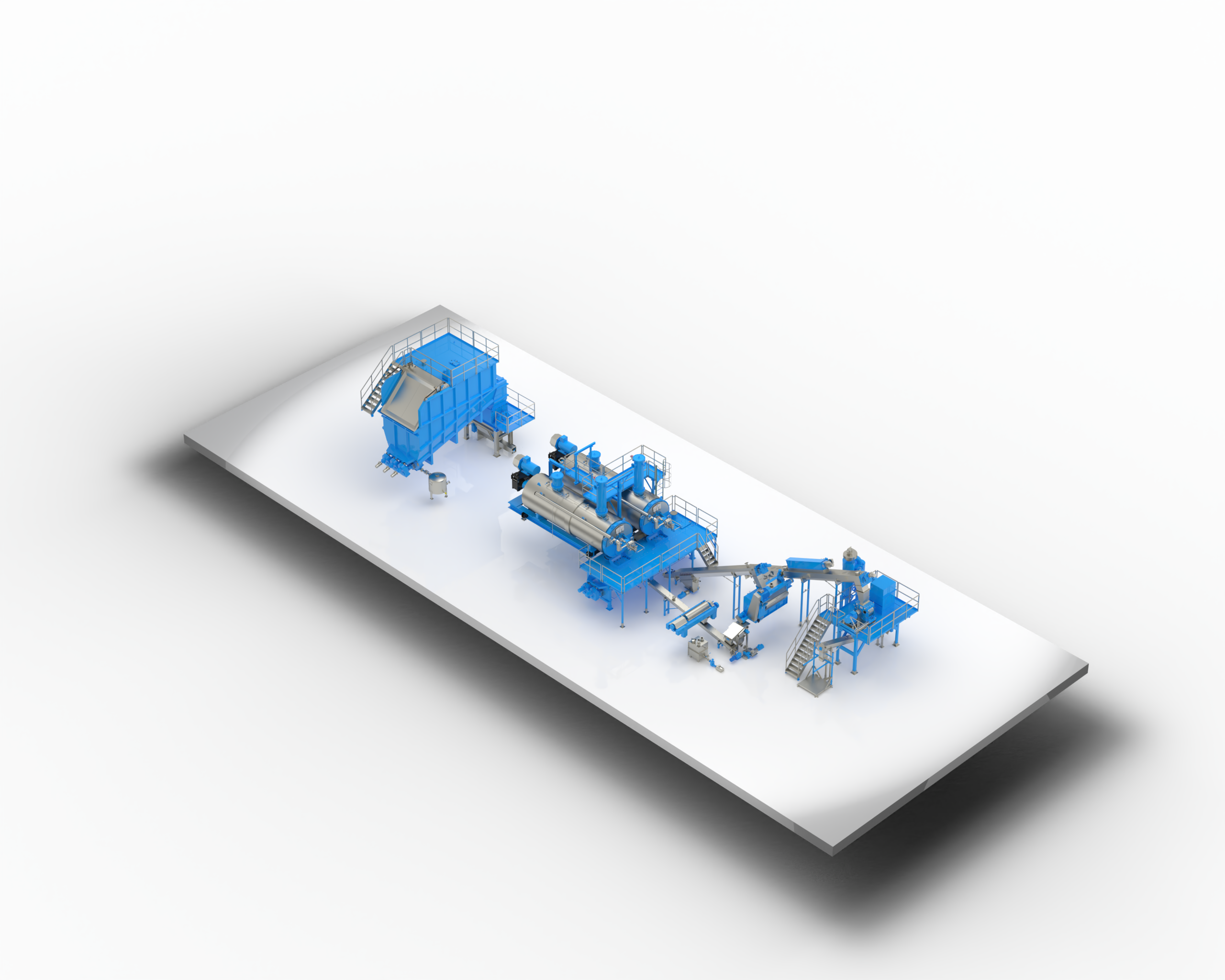

To transform animal byproducts and other organic waste into useful resources, rendering facilities is a crucial waste management step. Rendering factories may efficiently convert garbage into various usable byproducts using cutting-edge technologies and a thorough procedure. Collecting and transporting waste materials is the first stage in the rendering process. We work with various rendering plants that come in various sorts, forms, designs, and requirements. They process animal byproducts and are perfect for a variety of applications, including the processing of buffaloes, sheep, poultry, and many other types of animals. The items being supplied are low maintenance, work well, deliver results quickly, and so on. These are renowned for their high calibre and longevity. The Rendering Plants are user-friendly, safe, and operate without incident. To begin with, let’s understand what is a rendering plant.

What is the functional role of the rendering plant?

One of the most beneficial roles of contemporary slaughterhouses is that of rendering factories. To create products such as recycled meat, bone meal, and animal fat, deceased animals, abattoir wastes, and store rejects are recycled. These goods are marketed as a source of protein and other nutrients for use in pet meals, cattle feed, sheep feed, poultry feed, dairy animal feed, and swine feed. Additionally, animal fat serves as a source of energy in animal feed.

Furthermore, without operating rendering operations close to each contemporary abattoir, our communities would be at risk of being overrun by rotting and sick carcasses. The populace would become infected with deadly viruses and germs. According to one estimate, euthanized cats and dogs, as well as the bones, viscera, and blood from abattoir wastes and millions of other animals that were put to sleep by veterinarians and animal shelters, are turned into cattle feed each year, amounting to around 40 billion pounds.

Through this method, they unintentionally convert dairy cows, other cattle, and hogs—all naturally vegetarian herbivores—into carnivores.

Which merits do rendering plants offers?

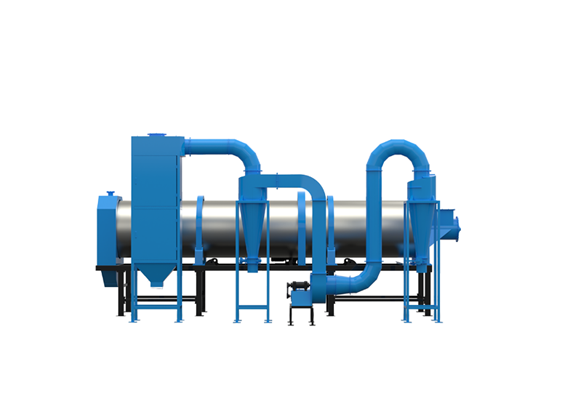

Lard, meal, grease, and other materials are made in rendering factories for the pet food industry. Temperature control is crucial throughout processing and storage to preserve the organoleptic quality of these value-added goods and to avoid overheating, oxidation, rancidity, or bacterial contamination. To avoid stinks and the emergence of objectionable aromas from foul gases, regulating the temperature of offal and animal waste in rendering factories is vital. Rendering, which fits smoothly into food preparation and uses better materials, is a potent way to enhance sustainable living. Products that are rendered have a variety of benefits:

- Sustainability:

Rendering provides a long-term sustainable solution, assisting in environmental protection and material recycling.

- Cost-effectiveness:

Rendering enables lower-cost product creation by using materials already on hand that would otherwise go to waste.

- Good for the Environment:

By reducing food waste and protecting the environment, rendering plant techniques enable more economically sensible and ethical animal feeding practices. The manufacturing of bio-based goods decreases our overall carbon footprint because they stop the release of carbon and other greenhouse gases (GHGs) into the environment.

- Building communities:

The rendering sector’s local, sustainable jobs benefit employees, the environment, families, and individuals.

Recycling Method of rendering plant:

- The raw product is heaped high on the rendering factory floor and is ready for processing. The mounds of dead animals appear to have a life of their own as millions of maggot’s swarms over the carcasses in the 90-degree heat.

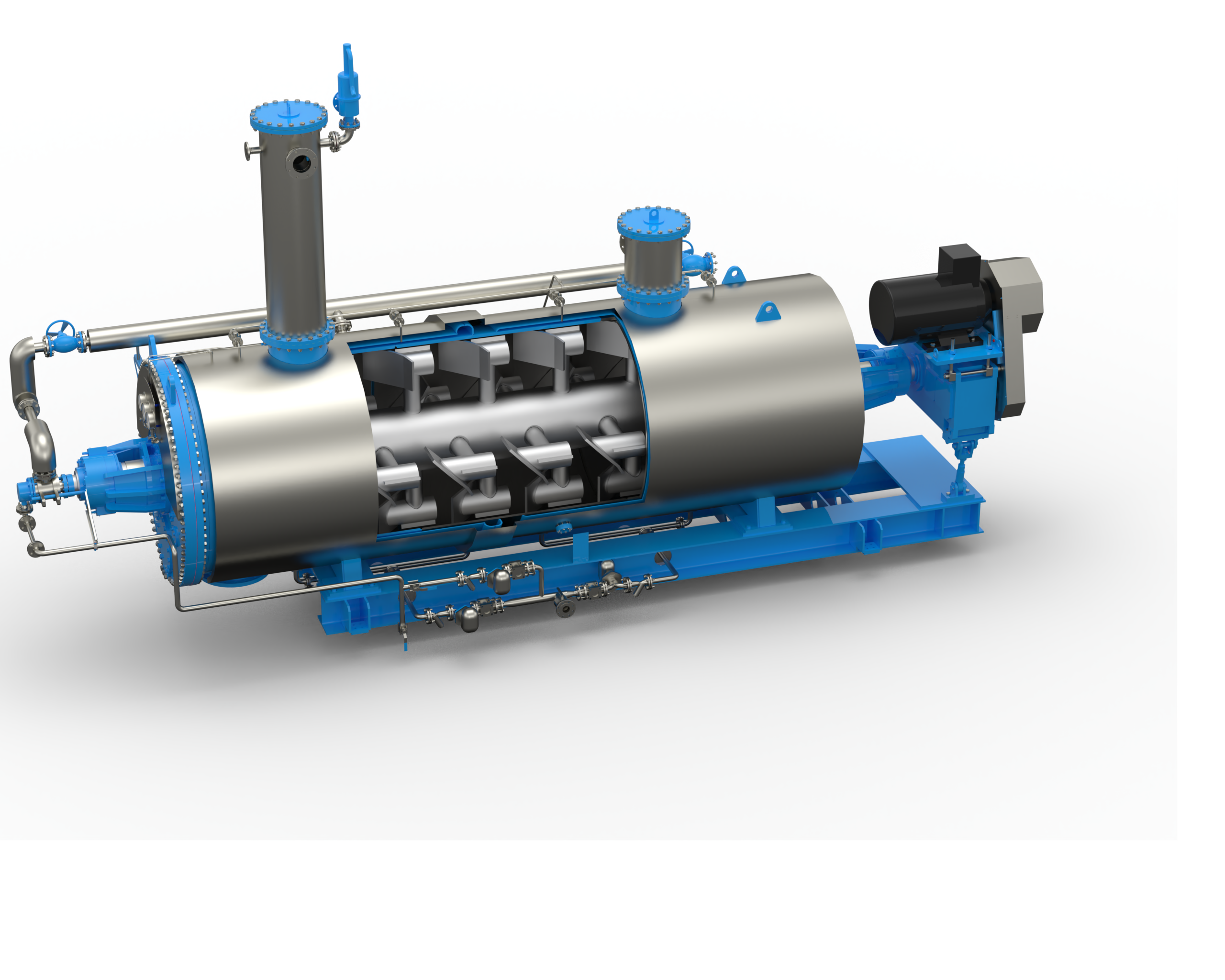

- The raw material is first divided into little bits to begin fine shredding and then sent to another drill. After that, it is cooked for an hour at 280 degrees. In the boiling “soup,” this process melts the flesh off the bones. This non-stop, round-the-clock batch cooking procedure occurs every day of the week.

- During this cooking phase, the soup creates tallow (animal fat) or yellow grease, which rises to the top and is skimmed off. A hammermill press releases the remaining moisture and turns the cooked meat and bone into a coarse powder. Large bone pieces and extra hair are removed using shaker screens. Presently, the following three goods are created:

- Repurposed meat

- Animal fat in colour yellow

- Bone food

- Since these meals are only used to feed animals, most state agencies spot-check and test for accuracy in labelling, asking questions like do the promises made by the rendering facility about the percentages of protein, phosphorous, and calcium match the actual amounts? Animal diets are not tested for pesticides and other poisons, and the testing must be more comprehensive.

Why does everyone utilize SunRise dependable industry resources?

At sunrise, we’re committed to giving renderers the tools they need to fight food waste with practical solutions. We provide materials that assist our members and business partners adhere to rules because we recognize how important regulatory compliance is to the sector. We also provide advocacy so that you may represent your views to decision-makers. In order to best serve our clients and consumers, we work worldwide to represent and enhance prospects for the rendering industry.

By paying attention to and assessing their requirements, offering guidance, and pushing for practical solutions, we assist our members in navigating end-user expectations, regulatory changes, and market upheavals.

Conclusion:

Rendering is a complex process crucial in various industries, such as agriculture, food processing, and waste management. It involves the transformation of animal by-products, such as slaughterhouse waste, into useful materials like animal feed, biofuels, and fertilizers. This blog post delves into what is a rendering plant, the process and benefits of rendering plants, shedding light on how they contribute to environmental conservation and the economy. SunRise works with clients to develop long-term strategies for competing in the market, create future development blueprints, build strong customer relationships, and become a reputable company.