Discovering the World of Poultry Rendering Plants Near Me

Discovering the World of Poultry Rendering Plants Near Me

Introduction to poultry rendering plants:

In sustainable agriculture, unsung heroes frequently serve important roles in the background. The facility that renders poultry is one such hero. These sometimes-disregarded facilities are essential for turning chicken waste into useful resources, helping to create a more ecologically friendly and long-lasting agricultural sector. These plants also have important environmental effects that must be recognized and dealt with. In this blog article, we will examine the most recent research on the effects of poultry rendering factories on the environment.

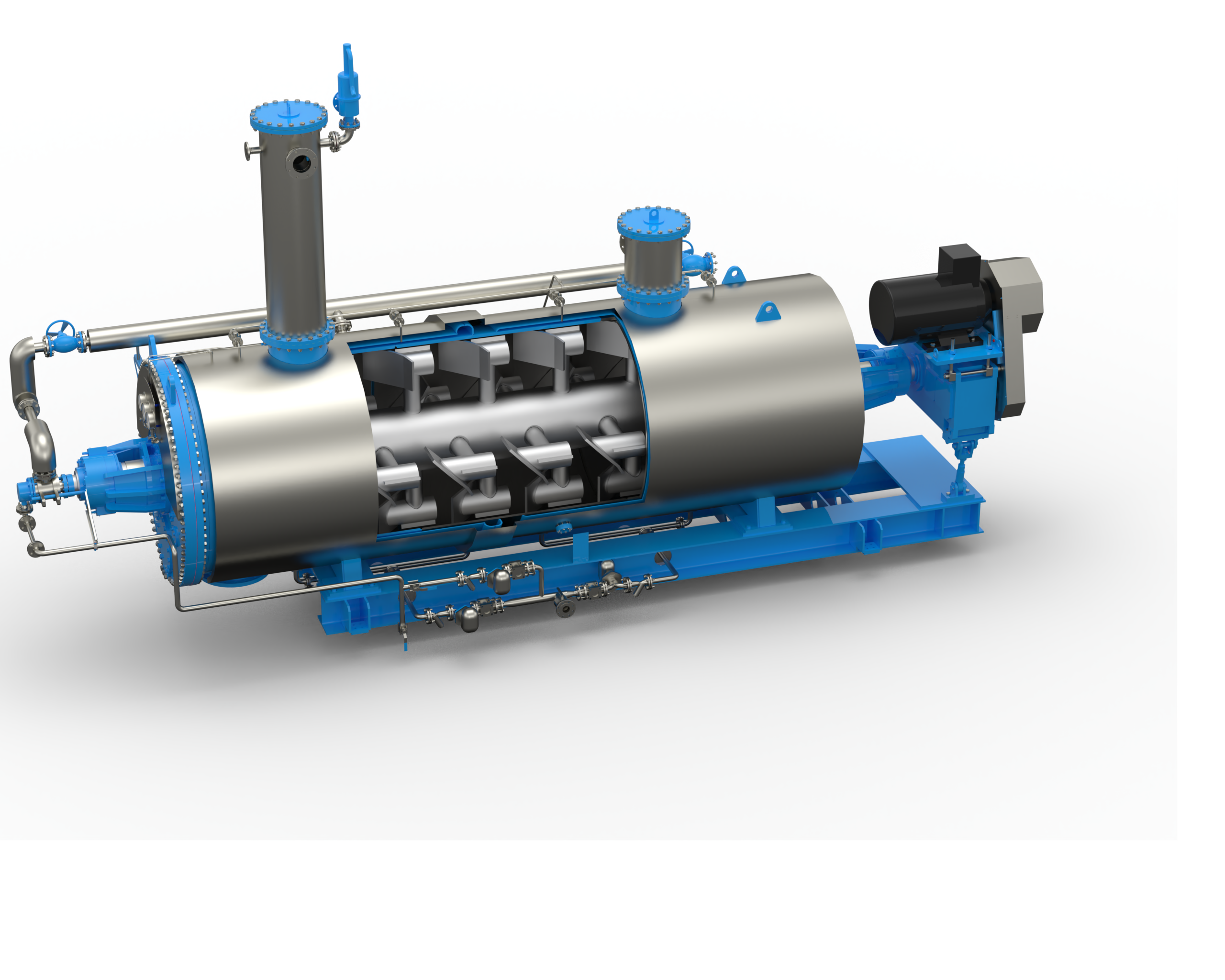

- The raw material is divided into smaller pieces and heated in a sizable Sunrise Batch Cooker until it liquefies. After cooling, the liquid material is strained through a filter press to produce a high-quality protein meal and a thin fat known as tallow.

- For more than 100 years, dead chickens have been rendered and utilised largely as animal feed. However, there has been a rise in interest in alternative fuels made from chicken byproducts in recent years. These fuels may produce heat or power without polluting the environment.

- The process of rendering dead chickens yields materials that, in addition to being utilised as an alternative fuel source, may also be used as fertilizers for gardens and lawns.

Future Trends and Innovations in poultry rendering plants:

- Improvements in Energy Efficiency

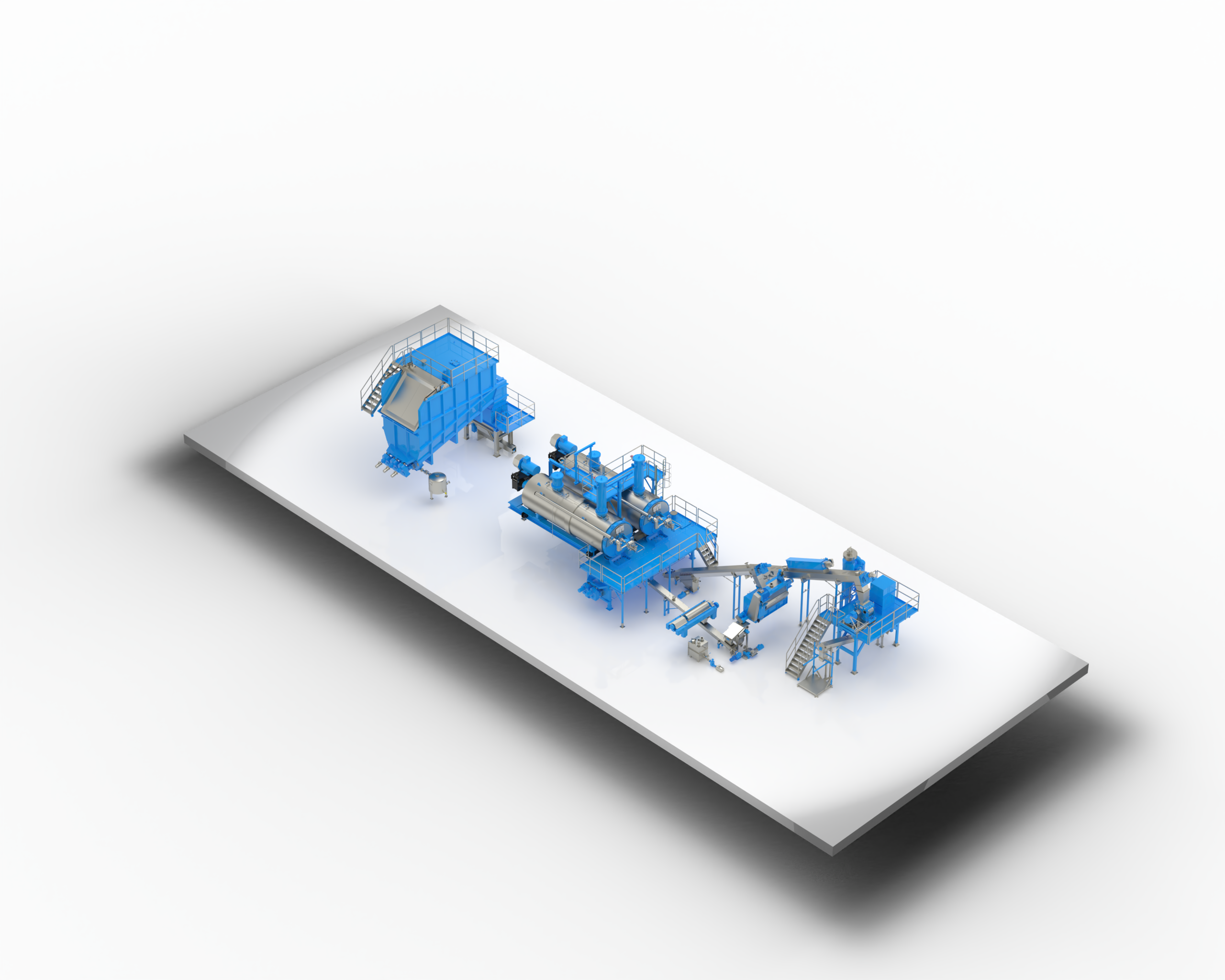

The demand for chicken rendering factories to increase energy efficiency is growing as worries about resource usage and carbon emissions rise. Innovative heat recovery systems are being created by manufacturers like Jiangsu SunRise Environmental Protection Technology Co. Ltd to address this issue. These systems efficiently reduce energy consumption and operational expenses by capturing and using waste heat produced during the rendering process. Poultry rendering factories may support sustainability efforts while continuing to be profitable by maximizing their energy efficiency.

- Enhanced Waste Management

Significant trash from rendering factories is produced, including feathers, blood, and offal. These by-products’ value may increase, and environmental impact can be reduced with effective waste management. Manufacturers are consistently developing new, creative methods to deal with this issue. For example, Jiangsu SunRise Environmental Protection Technology Co. Ltd has developed cutting-edge separation and purification technologies that effectively remove useful components from trash, such as proteins and lipids. The circular economy may be supported, and waste can be reduced using these recovered materials to produce animal feed, biofuels, and other products.

- Automatic Process Control

Modern companies have prioritised automation, and chicken rendering factories are no different. Leading the charge in poultry rendering plant intelligent process automation is Jiangsu SunRise Environmental Protection Technology Co. Ltd. These facilities may optimize the rendering process, reduce human error, and increase overall efficiency by using cutting-edge sensors, machine learning algorithms, and robots. Intelligent automation not only boosts operational effectiveness but also lowers the chance of contamination and assures constant product quality.

- Sustainability in the Environment

Poultry rendering factories place a high focus on sustainability, and producers are investing in green technologies. To reduce emissions of volatile organic compounds (VOCs) and pungent gases, advanced air pollution control technologies, such as multi-stage scrubbers and electrostatic precipitators, are being used. Additionally, cutting-edge wastewater treatment technologies are used to lessen the impact of rendering plant effluents on the environment. These initiatives ensure poultry-rendering factories coexist peacefully with the local populations and environment.

What Takes Place at a Rendering Plant near me?

A rendering factory is a facility that turns animal waste into items like fertilizer or animal feed. The term “rendering” describes several procedures, such as high temperature and pressure cooking, that transform slaughter waste and dead animals into fat and meat meals that may be utilised in other products. Around the world, corpses from farms and slaughterhouses are disposed of in rendering facilities. They are also prevalent in certain sizable hatchery facilities where they perform safe processing on poultry that has not hatched or been culled.

Local government agencies have tight laws governing poultry rendering plants near me that are intended to ensure they run safely and effectively. However, there have been unlawful activities at rendering operations, including air pollution from strong odours released during the rendering process and environmental contamination from the discharge of waste materials into nearby waterways.

Tips To Make Rendering Plant Machines Near Me Better

Most of these issues may be resolved using top-notch Sunrise tools and gear.

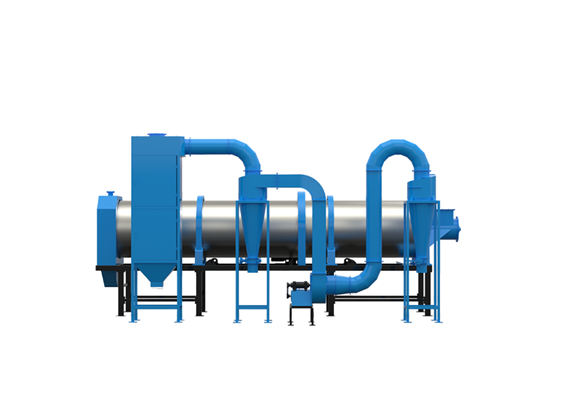

- Because of their high-water content, a lot of steam is produced while processing the solid wastes used in rendering facilities to treat animal products. Hazardous gas is present in this steam, which causes the surrounding region to smell terrible. Using sunrise air cooled condenser equipment in rendering factories to separate steam from other gases is another way to address this issue.

- The rendering process generates a lot of dust, and the workers in rendering facilities may experience major health issues. We can address this issue using Sunrise cyclone dust collector technology at rendering factories, which lowers dust particles to an acceptable level. To further eradicate the dangerous gas, the gas insoluble in water is condensed by the Sunrise meal cooler and then cleaned acid-base by the scrubbing tower.

Jiangsu SunRise Environmental Protection Technology Co. Ltd.’s Function:

The experience of Jiangsu SunRise Environmental Protection Technology Co. Ltd in creating and modifying equipment for poultry rendering factories is well known. We have established ourselves in a prominent position in the business because of our creative ideas and dedication to client satisfaction. The following are some of our main selling points:

- Engineering Innovations and Concepts:

We use cutting-edge engineering concepts to create cutting-edge equipment that satisfies the particular needs of poultry rendering facilities. We may add cutting-edge features and improve the overall performance of our equipment thanks to our ongoing research and development activities.

- Quality Control and After-Sales Support:

We adhere to stringent quality control standards throughout the production process to guarantee that our equipment fulfils the highest dependability, durability, and performance requirements. Additionally, we go above and beyond the sale to ensure client pleasure by offering full after-sales support, which includes maintenance services and replacement parts availability.

Conclusion:

To optimize resource use and optimize operations, poultry rendering plants near me rely on specialized technology and equipment. Manufacturers like Jiangsu SunRise Environmental Protection Technology Co. Ltd. play a crucial role in the business by providing cutting-edge solutions and a wide range of customisation possibilities. We can optimize their operations while adhering to safety and hygienic regulations because of our engineering, fabrication, and after-sales service competence. The future of poultry rendering facilities is bright because of ongoing improvements in engineering and manufacturing, and specialized equipment will continue to be crucial to our success.