Bone Meal Machine: What Do You Know

Bone Meal Machine: What Do You Know

In recent years, the bone meal has gained popularity as a sustainable, organic, and nutrient-rich alternative to synthetic fertilizers. As more farmers and gardeners embrace eco-friendly practices, the bone meal machine has emerged as a game-changing tool for producing this resource.

Sunrise Bone Meal Machine is a leading manufacturer of high-quality equipment for the processing of animal by-products. Its range of machines and equipment is designed to meet the specific needs of industrial companies in the animal processing industry. Whether you need a Disc Dryer, Continuous Cooker, Buffer Bin, or Cyclone Dust Collector, Sunrise Bone Meal Machine has the right solution for your business.

What is Bone Meal Machine?

Bone meal is a finely ground, a nutrient-rich powder made from animal bones. It is an excellent source of phosphorus, calcium, and trace elements, essential for plant growth and overall health. Bone meal improves soil structure and encourages root development, leading to stronger, more resilient plants.

A bone meal machine is a device used for grinding or pulverizing animal bones into a fine powder or meal. The resulting bone meal is commonly used as a fertilizer in agriculture, as a supplement for animal feed, or as an ingredient in pet food. Bone meal machines are typically composed of a grinding chamber, a motor or engine to power the grinding mechanism, and various screens or filters to separate the ground bone particles from any larger pieces.

The Bone Meal Machine: How it Works

The bone meal machine is designed to process animal bones efficiently and safely. Here’s a step-by-step overview of the process:

1) Raw Material Collection: Bones from slaughtered animals or food processing byproducts are collected, cleaned, and sorted based on size and quality.

2) Crushing: The bones are crushed into smaller pieces using a bone crusher or a hammer mill, making them easier to process.

3) Boiling: The crushed bones are boiled to remove any remaining fat, connective tissue, and impurities. This step also sterilizes the bones, ensuring a safe, pathogen-free product.

4) Drying: The boiled bones are then dried using specialized equipment like a rotary dryer or a fluidized bed dryer to remove moisture.

5) Grinding: The dried bones are ground into a fine powder using a bone meal grinder.

6) Packaging: The bone meal is then packaged and stored for use or sale.

The Benefits of Bone Meal Machines

The use of bone meal machines brings several advantages for farmers, gardeners, and the environment:

1) Waste Reduction: Bone meal machines transform waste from the meat industry into a valuable resource, reducing landfill waste and lowering the carbon footprint of the agricultural sector.

2) Nutrient-Rich Fertilizer: Bone meal is an excellent source of essential nutrients for plants, improving soil fertility and boosting plant health.

3) Sustainable Agriculture: By using bone meal, farmers can decrease their reliance on synthetic fertilizers, promoting more sustainable and eco-friendly agricultural practices.

4) Cost-Effective Solution: Producing bone meals on-site with a bone meal machine can be more cost-effective than purchasing commercial fertilizers, especially for small-scale farmers and gardeners.

5) Animal Feed Supplement: In addition to its use as a fertilizer, bone meal can also be used as an animal feed supplement, providing essential nutrients to livestock.

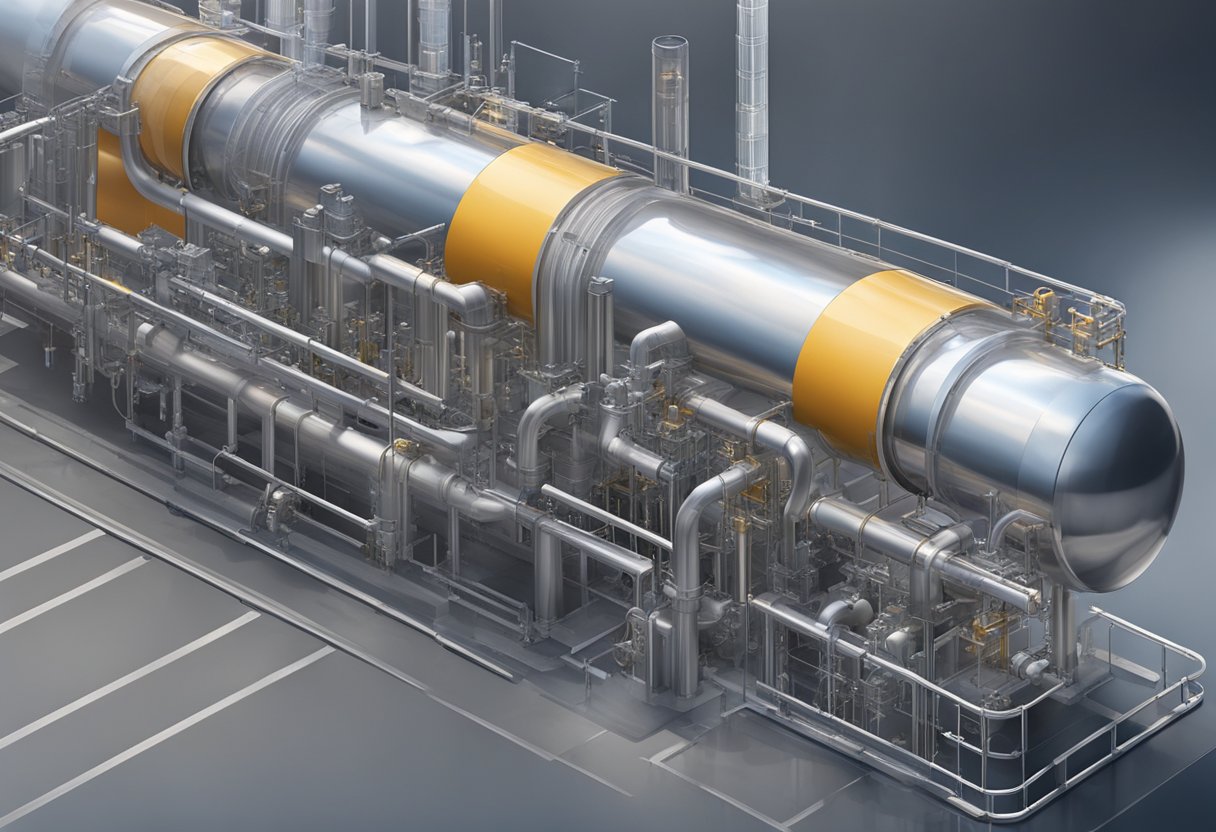

Sunrise Bone Meal Machine: Disc Dryer

The Sunrise Bone Meal Machine Disc Dryer is a high-quality, industrial-grade machine that is designed for continuous cooking or drying of animal by-products or fish. This disc dryer utilizes an indirect steam heating method to ensure maximum evaporation capacity in a compact design.

The design of the disc dryer is based on a central pipe on which vertically arranged and parallel discs with double walls have been welded. This design results in a concentrated heating surface that offers maximum evaporation capacity in a compact design. This makes it ideal for industrial applications that require large-scale drying or cooking of animal by-products or fish.

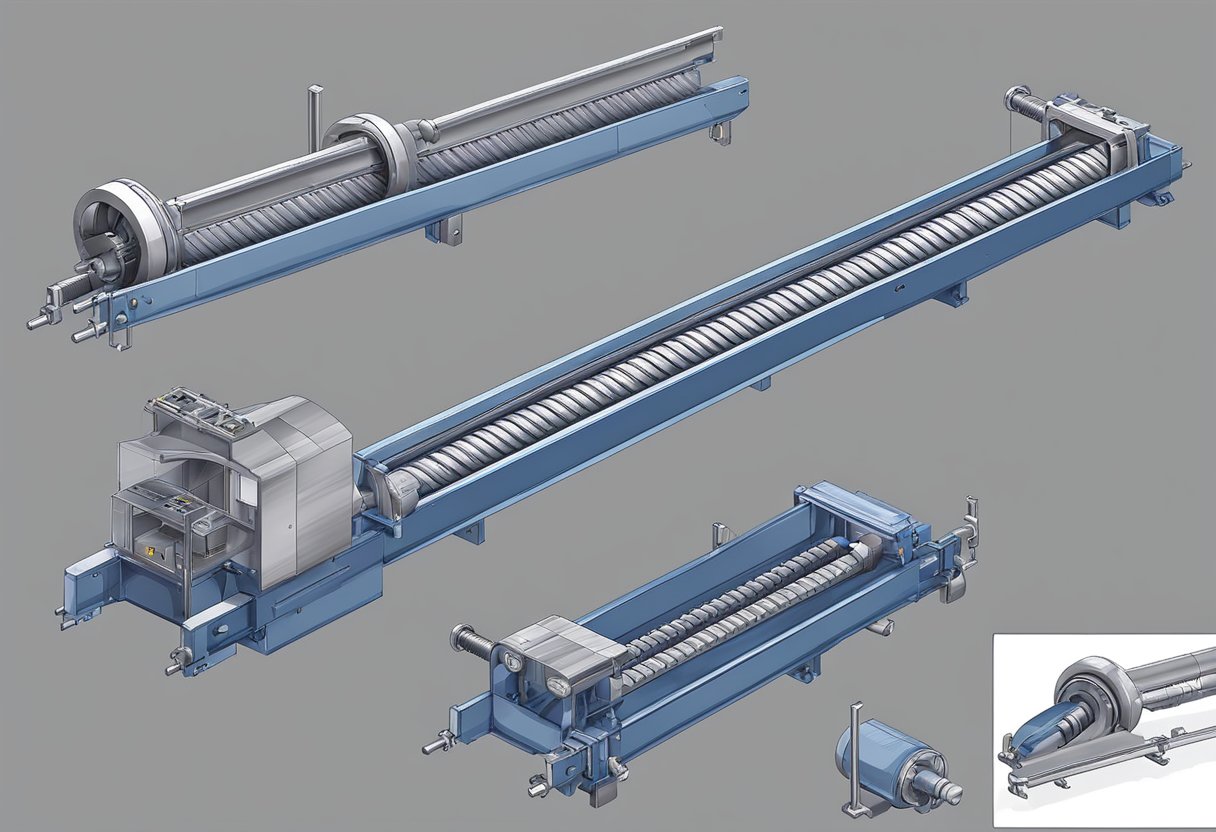

Sunrise Bone Meal Machine: Continuous Cooker

The Sunrise Bone Meal Machine Continuous Cooker features a rotating steam-heated multi-tubular shaft inside the body of the cooker, providing a large heating surface. This design ensures efficient and even cooking of materials being processed, resulting in a high-quality finished product.

The U-shaped body of the continuous cooker has a multi-tubular long-life shaft that is heated by steam (maximum 10 bar). This allows for precise control of the cooking temperature, which can be adjusted according to the requirements of the process and the type of raw material being processed

Sunrise Bone Meal Machine: Buffer Bin

Sunrise Bone Meal Machine Buffer Bin is an essential component of any industrial process that requires temporary storage of materials or products. With its versatility and range of applications, the buffer bin is an invaluable tool for businesses looking to streamline their operations, reduce costs, and ensure that they are able to meet customer demand.

For example, in the supply chain, buffer bins can be used to hold items waiting to be shipped or received. This can help keep the flow of goods steady, reducing inventory costs and the risk of stockouts. By maintaining a buffer stock of goods, businesses can reduce the risk of supply chain disruptions and ensure that they are able to meet customer demand.

Sunrise Bone Meal Machine: Cyclone Dust Collector

Sunrise Bone Meal Machine Cyclone Dust Collector is an essential component of any industrial process that involves the release of trace material into the air. The cyclone dust collector uses centrifugal force to separate heavy particles from the air stream, helping to remove dust and other particulate matter from the air.

Cyclone dust collectors are also commonly used in woodworking and other dusty operations, where they help to remove sawdust, wood chips, and other debris from the air. This helps to protect the health of workers and prevent damage to the equipment caused by the buildup of dust.

Conclusion

The bone meal machine is a significant innovation in the world of organic fertilizers, transforming waste into a valuable resource and promoting sustainable agricultural practices. As more farmers and gardeners embrace this technology, we can expect a brighter, greener future for our planet. So, let us continue to explore and invest in eco-friendly solutions like the bone meal machine and lead the way toward a more sustainable world.