Description

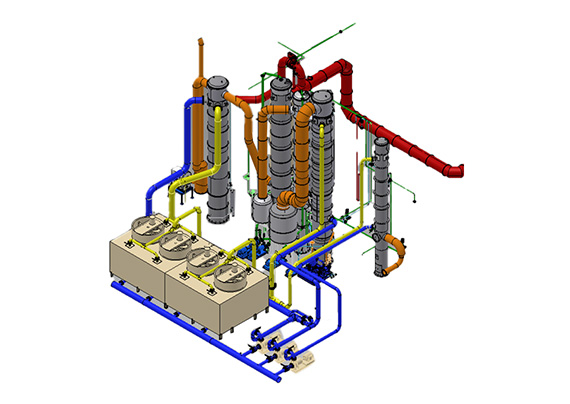

Evaporation Concentration System Application

Jiangsu Sunrise Evaporation Concentration System use waste heat from cooker and dryer or steam to concentrate the stagnant water containing the protein, make the enrichment of concentrate for further processing.

Design characteristics

1. The waste heat evaporator and the steam evaporator operate with the falling film principle.

2. Falling film principle advantage: The process fluid is fed to the top of evaporator and is evenly distributed in the pipes. When the fluid flows through the downward flow of gravity, it forms a thin film on the inner surface of pipe. The film principle has a shorter retention time and lower working temperature, thus, the degradation of the product is minimized.

3. The design adopt the tubular structure, and the baffle is designed between tubular to achieve the desired evaporation effect.

4. The tube medium is stagnant water with protein, the shell medium is the waste heat from cooker and dryer or pure steam.

5. Evaporator is manufactured in stainless steel.

Evaporation Concentration System Advantage

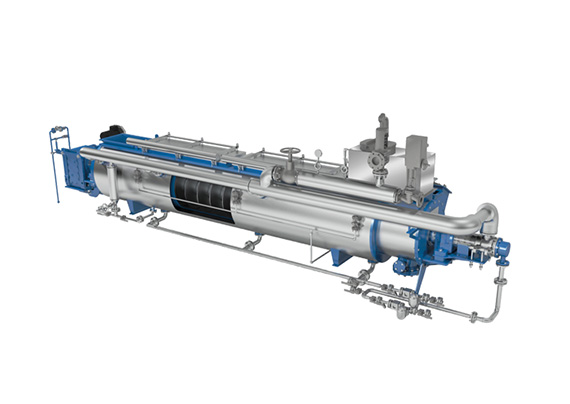

Waste heat evaporator

1. Especially in drying procedures, operations are frequently carried out under atmospheric pressure, resulting in the discharge from the dryer likely comprising a blend of air and water vapor.

2. By cooling such gases in a waste heat evaporator, a small or large part of the heat energy used in the drying process may be recovered in the waste heat evaporator.

3. In the case of process vapours with very small amounts of non-condensate– e.g. from traditional multistage evaporators – all heat energy may be recovered in the waste heat evaporator.

4. Low investment and operating costs

5. Comprehensive waste heat utilization

6. No need of live steam supply

7. Minimized impact on product

8. Quick start-up and shutdown.

9. Flexible and easy operation.

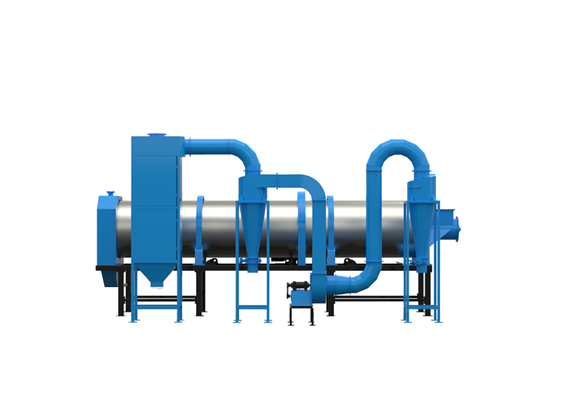

steam evaporator

1. The steam evaporator operates with the falling film principle, and thus it can be considered an independent of waste heat.

2. The steam evaporator utilises live steam as energy source, allowing for higher concentrations of the solution.

3. Several steam evaporators can be installed. Additionally a steam evaporator can be installed as a finisher connected to waste heat evaporator for boosting the capacity.

4. Low investment cost.

5. Quick start-up and shutdown.

6. Flexible and easy operation.

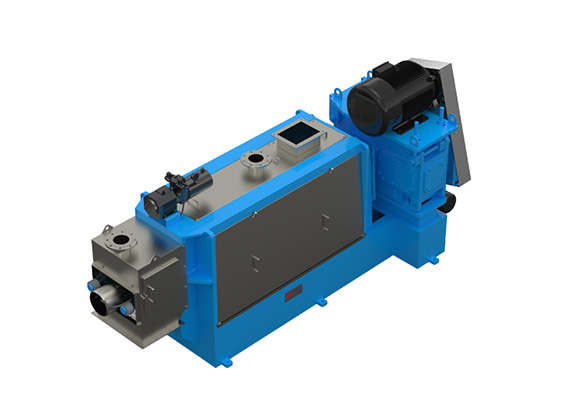

Waste heat evaporator + steam evaporator

1. The time exposing the products in high concentration is minimized.

2. exposure temperature is minimized.

3. High concentration, low cost.

4. Achieve higher productivity.

Technical parameter

| Model | Capacity |

| YRZF | According to customer requirement |

| ZQZF | According to customer requirement |