Description

Application

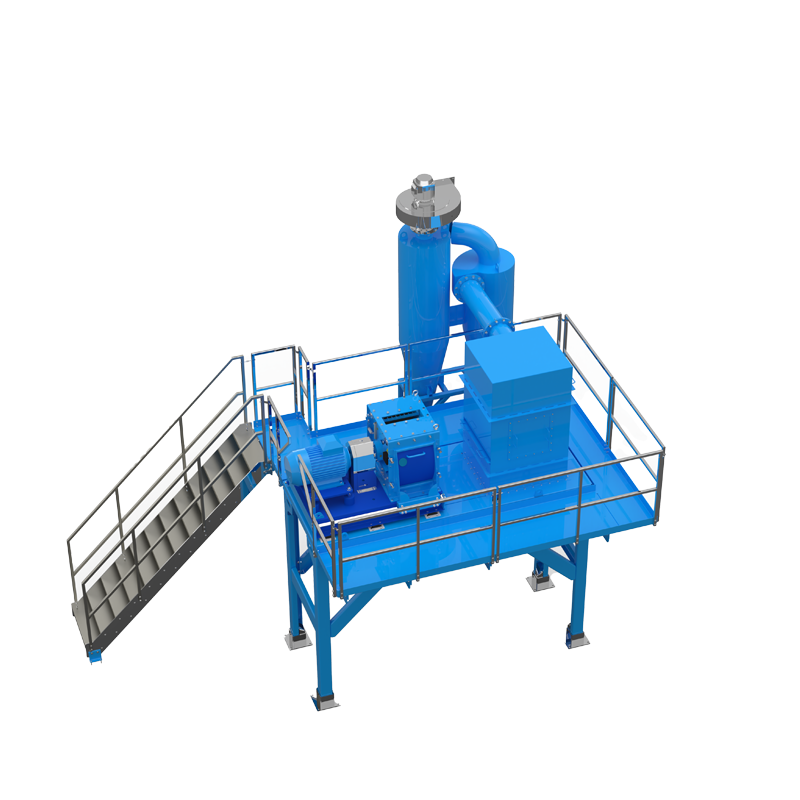

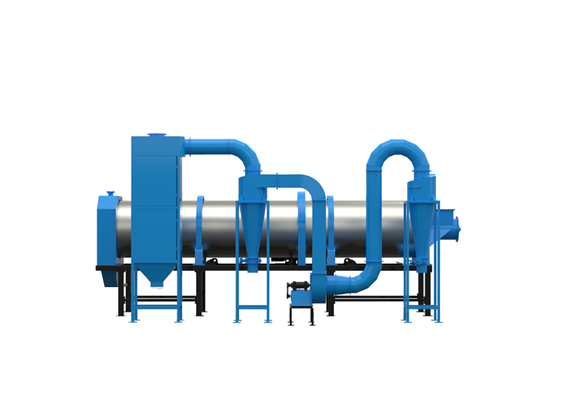

Jiangsu sunrise milling plant is used to reduce the particle size of the greaves after fat extraction, make the meat and bone meal even. The reduction in size required at this stage depends on whether the meal is used directly in compound feeds or it will be passed through a further stage of size reduction.

A milling plant is an establishment designed to transform diverse materials, such as grains or other agricultural commodities, into finalized products like flour or other edible goods. The precise utilization of a milling plant will be contingent upon the nature of the material undergoing processing and the intended final product.To illustrate, a wheat milling plant would refine wheat into flour, whereas a corn milling facility would handle corn, producing an array of items like corn starch, corn syrup, and animal feed. The standard procedure typically encompasses tasks like cleansing, grinding, and sifting the raw materials, and might also encompass additional stages such as drying or packaging.

Design characteristics

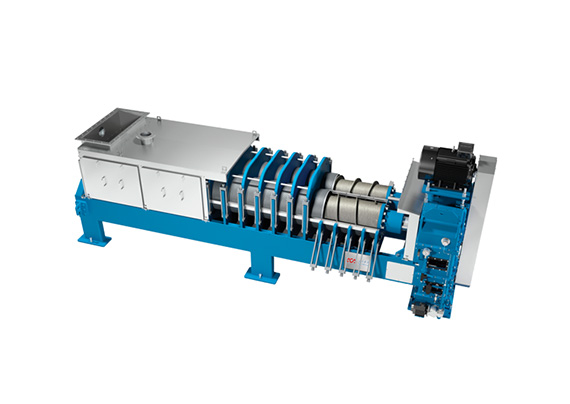

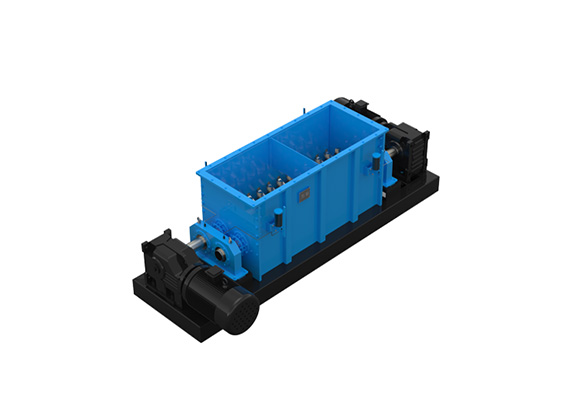

1. The milling plant is of a robust construction manufactured entirely from mild steel. The interior chamber of the mill has replaceable wear plates at each end of the rotor assembly and a stone trap at the bottom.

2. The hammers, which are case-hardened to give extended life, are reversible so that all four edges can be utilised before a new set is required.

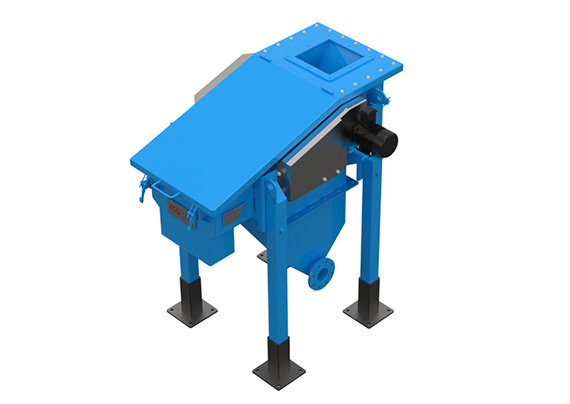

3. The milling plant consists of: hammermill, coupling and motor mounted on a common base frame fitted with vibration dampers. A separation fan and a Co-Jet filter ensure high capacity and prevent excessive temperature increases.

Technical parameter

| Model | Motor (KW) | Capacity Meat and Bone Meal (t/h) | Capacity Fish Meal (t/h) |

| XSXT45 | 37-55 | 1-3 | 1.5-35 |

| XSXT60 | 45-75 | 2-4 | 3.5-8 |

| XSXT80 | 55-110 | 4-6 | 8-11 |

| XSXT100 | 75-160 | 5-10 | 11-15 |

Meat and bone meal density is 600 kg/m3, mesh is Ø10mm. Capacity depends on bone quantity, grease and water quantity, pressed cake temperature.

Fish meal density is 500 kg/m3, mesh is Ø16mm. Capacity depends on fish type, moisture and oil quantity and temperature.

Milling Plant FQA

1、What is used for?

A milling plant is used for grinding and processing grain into flour.

2、What are the components ?

The main components of a milling plant include a cleaning system, grinding/milling machines, sifting and packing equipment.

3、How does work?

The sequence commences by purifying the grain to eliminate impurities. Subsequently, the grain undergoes grinding through milling machinery to yield flour. This flour is sifted to extract larger particles and categorized into distinct grades. Ultimately, the flour is readied for retail by undergoing packaging.

4、What are the factors to consider when setting up a milling plant?

Location, available resources (grain, water, electricity), market demand, cost, equipment, storage and transportation facilities, and government regulations.

5、What are the benefits ?

Enhanced efficiency, consistent flour quality, heightened command over the production process, capability to generate a broader spectrum of flours, and the prospect of cost reduction.