Shell And Tube Condenser / Condenser Shell And Tube

- Brand: Sunrise

- Application: Feather Meal Project | Fish Meal Plant | Meal Plant & Fat Plant | Rendering Plant

- Shipping: Air / Sea / Train / Truck

- Warranty Period: One Years with Lifelong Free Service

- Alias: shell and tube condensers / heat exchanger shell and tube /shell and tube heat exchanger / shell and tube heat exchangers

Description

Application

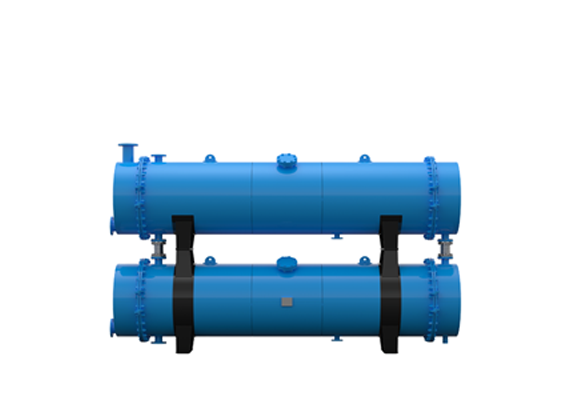

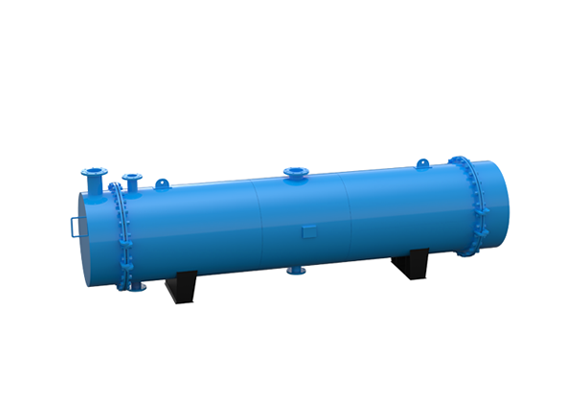

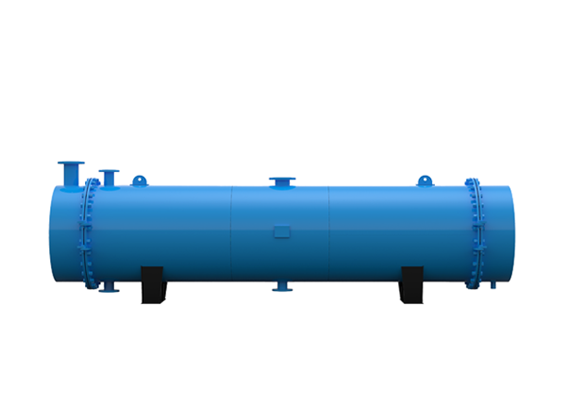

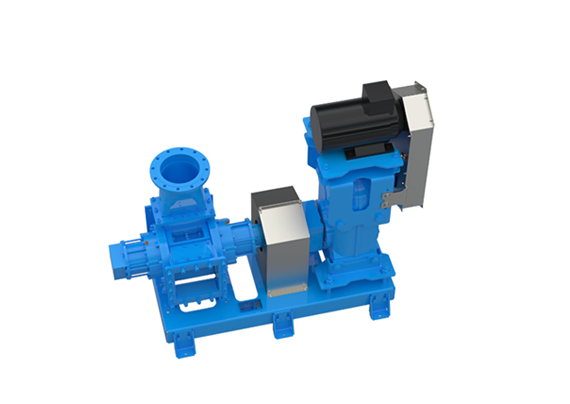

Jiangsu sunrise shell and tube condenser condenses the processing vapours emitted from cookers and dryers. They have two types: Vertical condenser (LSLN) and horizontal condenser (WSLN).

A shell and tube condenser is a type of heat exchanger that is commonly used in various industrial and HVAC applications. It consists of a tube bundle, which is enclosed within a cylindrical shell. In this setup, one fluid (usually a liquid) courses through the tubes, while another fluid (typically a gas) circulates outside the tubes within the shell.The two fluids engage in a heat exchange process, wherein the fluid contained within the tubes transfers heat to the fluid encircling the tubes in the shell, resulting in the cooling of the internal fluid.Some common applications of shell and tube condensers include cooling of steam in power plants, condensing refrigerant in HVAC systems, and condensing process fluids in chemical plants.

Design characteristics

1. In shell and tube condensers the process vapours flow through the tubes while cooling water is passing over the external surface in a counter flow arrangement.

2. All connections are mounted with captive loose flange connections.

3. The shell and tube condensers can also be used as heat exchangers when recovering waste heat from the cooking processes.

4. The condensers can be equipped with a vacuum tank lowering the temperature and thereby increasing the effect.

| Model | Heat exchange area(m²) | Barrel diameter(mm) | Barrel length(mm) | weight(kg) |

| HRQ-WS-90 | 90 | 1000 | 3700 | 2400 |

| HRQ-WS-120 | 120 | 1000 | 4700 | 2900 |

| HRQ-WS-130 | 130 | 1000 | 5550 | 3000 |

| HRQ-LS-130 | 130 | 800 | 8800 | 2000 |

| HRQ-LS-270 | 270 | 800 | 8800 | 2800 |

Shell and Tube Condenser FQA

It is a type of heat exchanger that is commonly used in various industrial and HVAC applications. The shell, which is a cylindrical vessel, contains a number of tubes through which a second fluid (the coolant) flows. The fluid to be cooled (the process fluid) flows over the outside of the tubes. Heat is transferred from the process fluid to the coolant, causing the process fluid to cool.

1、What are the main components ?

-A typical configuration of a shell and tube condenser comprises a cylindrical shell, a bundle of tubes, a tube sheet, heat exchange tubes, and a coolant.

2、What are the advantages ?

-Advantages include high heat transfer coefficient, high thermal efficiency, flexibility in design, and ease of maintenance.

3、What are the typical applications?

-They find widespread application in power plants, chemical processing facilities, HVAC systems, and refrigeration setups.

4、What are the different types ?

-There are two main types : fixed tube sheet and floating head. In a fixed tube sheet condenser, the tube sheet is affixed to the shell, whereas in a floating head condenser, the tube sheet remains unattached to the shell.

5、What are the factors affecting the performance ?

-Various factors that can influence the efficacy of a shell and tube condenser encompass the coolant type employed, tube bundle configuration, fluid velocities, and the cleanliness of the tubes.

6、How to maintain a shell and tube condenser?

-Regular maintenance of a shell and tube condenser includes cleaning the tubes, checking for leaks, inspecting the tube bundle for damage, and monitoring the coolant levels.

7、What are the common problems ?

-Common problems with shell and tube condensers include leaks, blockages, low coolant levels, and damage to the tube bundle.

8、How to optimize the performance ?

-To optimize the performance of a shell and tube condenser, ensure that the coolant is clean and at the correct level, regularly clean the tubes, and monitor the fluid velocities.