Feather Meal Equipment: The Go-To Process For Feather Meal

Feather Meal Equipment: The Go-To Process For Feather Meal

What is feather meal equipment?

Feather meal is made from the feathers of slaughtered chickens, turkeys, geese, and other poultry. It can be used as an alternative to meat meals in animal feed or as a soil fertilizer for plants.

Feather meal equipment is a device that can be used to create feather meals, a type of animal feed. The machine is designed to grind up feathers and other poultry by-products into a fine powder that can be used as a protein-rich food source for livestock.

Feather powder is made by putting the slaughtered feathers from a poultry slaughterhouse into the sanitizing equipment of Moryoung, and then squeezing water and cooking them at high temperatures and pressure to produce valuable feather powder and reuse waste.

Sunrise Feather Meal Equipment Manufacturer offers different types of equipment to make feather meals, including:

Batch Cooker – Jiangsu sunrise batch cooker is designed for sterilization, hydrolyzation, and drying of animal by-products. The batch cooker is one of the most important parts of a dry rendering plant and is manufactured in three standard sizes to suit various plant capacities.

Milling Plant – Milling Plants are used to grinding up feathers into small pieces so that they can be incorporated more easily into other products like animal feed supplements

Cyclone Dust Collector – Cyclone Dust Collectors are used when grinding up feathers because they help keep down dust particles that could otherwise contaminate other products from being made.

Why use feather meal equipment?

Feather meal is a good source of nitrogen and phosphorus. It is used as a fertilizer for growing plants and a soil conditioner for sandy soils.

Here are the benefits of feather meals:

- Natural fertilizer – Feather meal is a natural, organic fertilizer that contains nitrogen and other nutrients that are beneficial to plant growth.

- Low cost – Feather meal is very inexpensive compared to synthetic fertilizers, especially when you consider that it’s made from waste products rather than mined minerals or petroleum products.

Feather meal equipment can help you save money by reducing labor costs associated with grinding feathers yourself. It also allows you to produce your own feather meal in large batches, which is safer than using an open-pit method.

Feather meal equipment comes with a variety of different features that make it easy to use. For example, some machines are designed with a built-in cooling system that keeps the product temperature down so it doesn’t heat up too much during processing.

There are many advantages of Sunrise Feather Meal Machines:

- 1. Easy Operation: It has a simple configuration design with no need for special knowledge or skills in operating or maintaining this machine.

- 2. Low Cost: The machine is easy to operate and maintain, and the cost of production is low.

- 3. High Productivity: The capacity can be increased according to your needs by changing the feeding speed, feeding size, and feeding amount per time.

- 4. Environmental Protection: With the use of this machine, there will be no pollution caused by dust during the production process because all raw materials are fed into the grinding chamber through an airlock device which prevents dust from being released into the air during operation and reduces environmental pollution at the same time.

How is the rendering of the feather meal done?

The process of making feather meals begins with collecting the feathers. Feathers are removed from slaughtered chickens and turkeys during processing at slaughterhouses or poultry facilities. They can then be washed to remove dirt, blood, and other impurities before being cooked at high temperatures to kill bacteria.

After being cleaned, the feathers are cooked at Sunrise Batch Cooker before being allowed to cool down. At this point, they are ready for grinding into powder form. This process can be done by using machinery like a Sunrise Milling Plant.

Feather meals may also be treated with chemicals like bleach or hydrogen peroxide to ensure that all bacteria have been killed before packaging and shipping it off for use in livestock feed production processes such as fertilizers or soil conditioners.

The crux of making feather meal

Feather meal is a byproduct of poultry processing, which is one of the main sources of protein and amino acids in animal feed. It can be used as an ingredient in animal feed or fertilizer because it contains vitamins A, B, and D, and minerals such as iron, zinc, and phosphorus.

If you’re looking to produce feather meals, you need to know the right way to do it. Feather meal is a byproduct of the poultry industry, and while it is sometimes used as an animal feed supplement, it’s only considered safe when produced correctly.

The crux of making feather meals is how to grind feathers into powder. Of course, you can use a food processor or an electric mixer. However, they are not good enough for large-quantity processing and will be very noisy. For this reason, you need to invest in a commercial-grade grinder such as Sunrise Milling Plant that will allow you to process the feathers with ease.

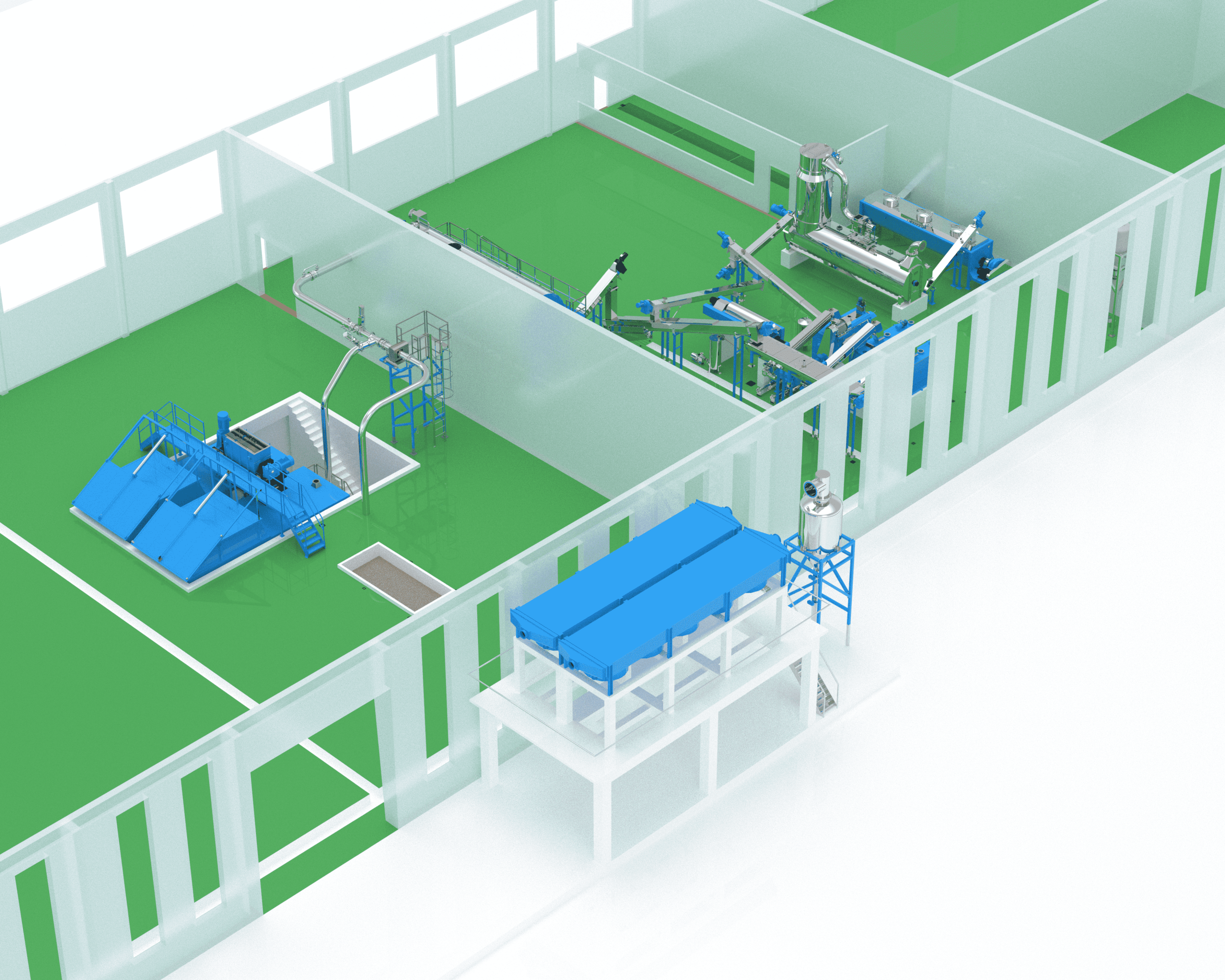

What’s more, building professional feather meal systems is also important for your industry to thrive. By investing in the right equipment, you can make sure that your business stays profitable and continues to grow over time.

Conclusion

Feather meal is a by-product of the poultry industry, which has been used as an organic fertilizer and animal feed. Sunrise not only can provide you with high-quality feather meal machines but also give you custom feather meal systems based on your industry features. Sunrise can provide customized solutions based on your requirements. Sunrise’s goal is to help you reduce operating costs while maximizing profits. Whether you need a single machine or a complete system, Sunrise will work with you to build the perfect solution for your needs.