Efficiency Unleashed: The Fat Screw Press in Rendering Equipment

Efficiency Unleashed: The Fat Screw Press in Rendering Equipment

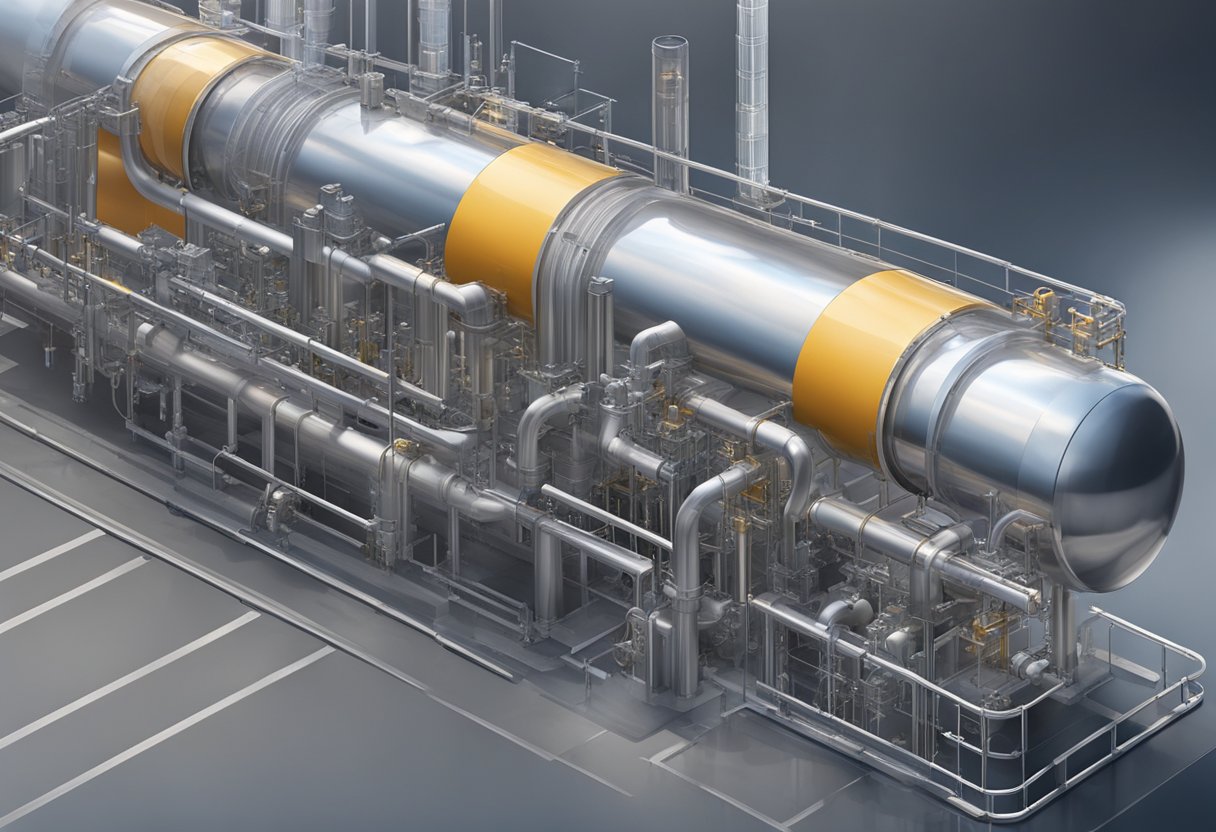

The invention of the fat screw press by William Lyman of Massachusetts in 1868 revolutionized the extraction of fats and tallow from animal carcasses. This mechanical device employs a screw-shaped auger to efficiently extract tallow and grease from animal carcasses during the pressing process.

Here’s how the fat screw press operates: The animal carcass is positioned above the screw press in a vat, which can be lowered into place using a rope pulley system until it reaches the bottom of the vat. Once in position, the auger is activated and begins to rotate, exerting pressure on the carcass and forcing out its fatty deposits through small holes along the length of the screw.

What sets the Fat Screw Press apart is its utilization of a screw conveyor, enabling the meat to move through the press at a notably high rate of speed. This design feature facilitates a much faster throughput of meat compared to manual or alternative pressing methods. As a result, you can process more meat through your press, ultimately translating into increased efficiency and profitability.

Minimizing Maintenance Expenses: The Fat Screw Press – A Low-Maintenance Rendering Solution

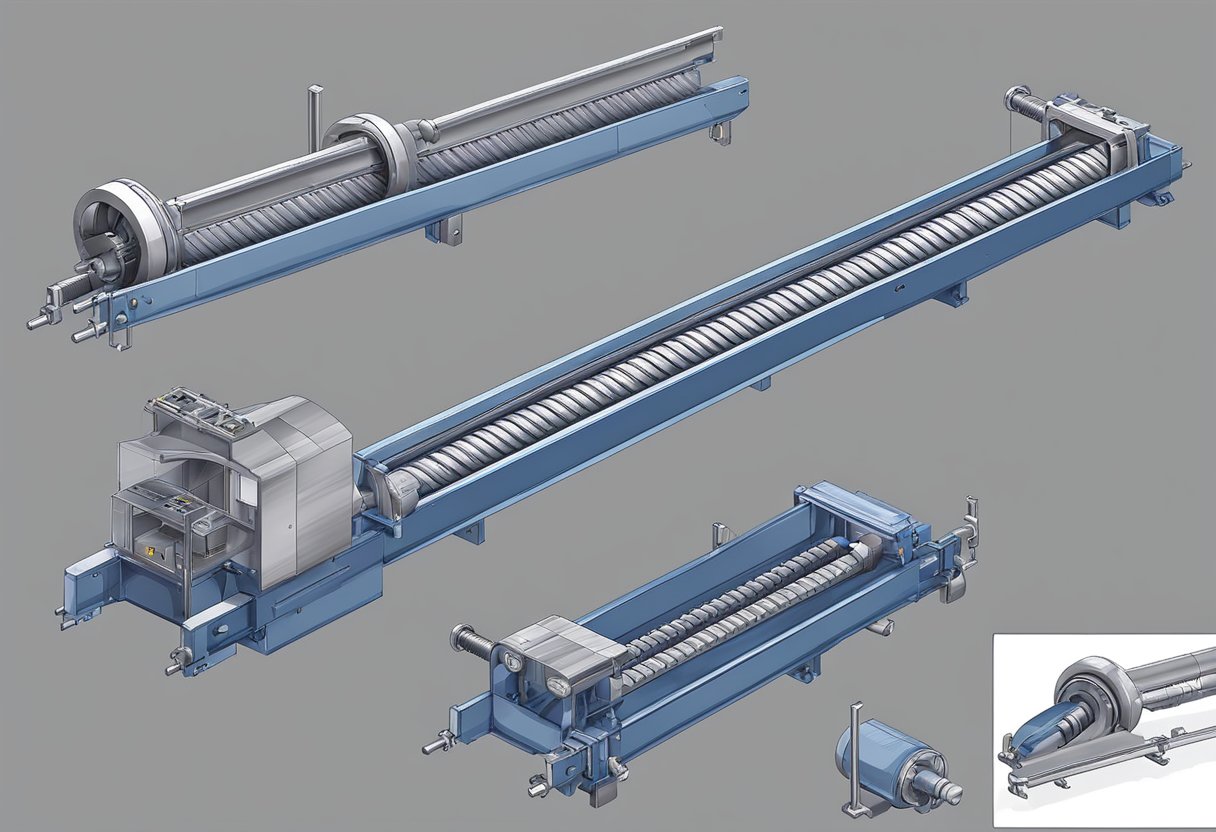

When it comes to maintenance costs, the fat screw press stands out as a remarkably cost-effective rendering machine. Its design prioritizes low-maintenance requirements, necessitating only minimal servicing. Key components of the fat screw press are crafted from stainless steel, a material renowned for its exceptional resistance to corrosion. Moreover, this rendering machine surpasses its counterparts in terms of durability, often enduring for years without the need for repairs or replacements.

Streamlined Operation of a Compact Rendering Apparatus

Simplicity and user-friendliness define the operation of the fat screw press. In stark contrast to other rendering equipment, it demands no specialized training or expertise for proficient use. The fat screw press features just a few controls that are intuitive and can be mastered within minutes of acquaintance.

Elevating Workflow Efficiency with High-Performance Fat Screw Presses

Furthermore, the fat screw press effectively diminishes labor costs. It empowers operators to carry out their tasks autonomously, eliminating the need for constant assistance or reliance on others. This rendering machine can be efficiently operated by a single individual or, in situations involving a high volume of material or complex operational factors, by two individuals working in tandem.

Reduces Material Spoilage and DownTime

The Fat Screw Press is indeed an essential component in rendering equipment, and it plays a crucial role in the rendering process by helping to reduce material spoilage and downtime. Here’s how the Fat Screw Press contributes to these benefits:

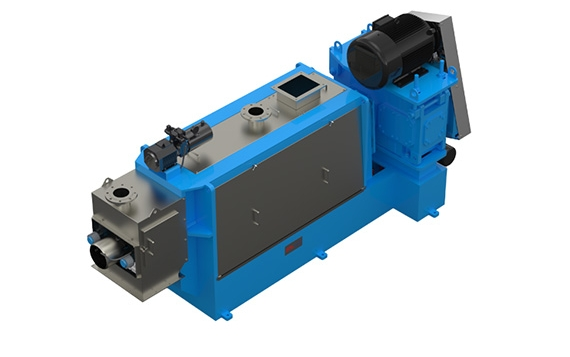

Enhanced Processing Speed

Fat Screw Presses are designed to operate efficiently and quickly. This enhances the overall processing speed of the rendering equipment. Faster processing means less downtime, which can be especially important in large-scale rendering facilities where continuous operation is essential to meet production demands.

Minimized Equipment Maintenance

Efficient separation of fat and solid materials can help reduce wear and tear on other components of the rendering equipment, such as the cooker or centrifuges. This can extend the lifespan of the equipment and reduce downtime for maintenance and repairs.

Enhanced Productivity

By effectively separating fat and solid materials, rendering equipment with a Fat Screw Press can maintain a consistent and continuous production flow. This leads to enhanced productivity and reduced downtime due to equipment stoppages.

the Fat Screw Press is a critical component in rendering equipment, and its efficient operation helps minimize material spoilage and downtime. It plays a pivotal role in ensuring that valuable resources are recovered effectively during the rendering process, contributing to both economic and environmental benefits for rendering facilities.

Operates Efficiently at Reduced Temperatures

The innovative Fat Screw Press technology is engineered to function at lower temperatures, achieving remarkable energy savings and cost reductions.

Innovative Fat Screw Press for Efficient Separation of “Poultry Byproduct” from Meat

This groundbreaking fat screw press excels at the continuous separation of fat from lean. Before entering the press, a screw within the fat screw press meticulously mixes and homogenizes the raw material, significantly enhancing the efficiency of fat-protein separation.

Pressure Fat Screw – A Secure, Efficient, and Convenient Rendering Solution

The screw’s unique design allows the fat screw press to operate at lower temperatures compared to conventional rendering equipment, resulting in reduced energy consumption and heightened product yield.

Complementing its distinctive design, the fat screw press also incorporates an adjustable pressure plate, ensuring consistent outcomes with each batch of processed meat products.

Requires No Air Filters

It’s true that Fat Screw Presses used in rendering equipment typically do not require air filters. Fat Screw Presses are mechanical devices designed for the separation of fat from solid materials during the rendering process, and they operate without the need for air filtration systems.

Fat Screw Presses Are The Next Breakthrough In Winter Fuel Production

Fat Screw Presses function through mechanical means, primarily through the rotation and compression of materials. They do not rely on airflows or gas exchange for their operation. Instead, they use a screw or auger mechanism to squeeze fat out of the solid materials.

Keeping Air Quality High Using Fat Screw Press

Rendering equipment, including Fat Screw Presses, is designed as a closed system to prevent the release of odors, particulates, and contaminants into the surrounding air. This design minimizes the need for air filtration because it contains the process within the equipment.

Fat Screw Presses Suck Fat Like No Other

Fat Screw Presses are designed specifically for the separation of fat from solid rendering materials. Their function is distinct from processes that require air filtration, such as industrial air scrubbers used to control emissions from combustion processes or chemical reactions.

While Fat Screw Presses themselves do not require air filters, it’s important to note that rendering facilities as a whole may employ air filtration and odor control systems to manage any potential emissions and maintain compliance with environmental regulations. These systems are typically separate from the Fat Screw Presses and other rendering equipment and are designed to capture and treat any odors or airborne particles that may be generated during the rendering process.

CONCLUSION

Rendering facilities may employ separate air filtration and odor control systems to manage emissions and ensure compliance with environmental regulations. These systems are designed to capture and treat any potential odors or airborne particles generated during the rendering process, but they are distinct from the operation of the Fat Screw Press itself.

Overall, the Fat Screw Press contributes to the efficiency and productivity of rendering operations while helping to minimize material waste and downtime, making it a valuable component in the rendering industry.