Feather Meal Machine

What is Feather Meal Processing Machinery?

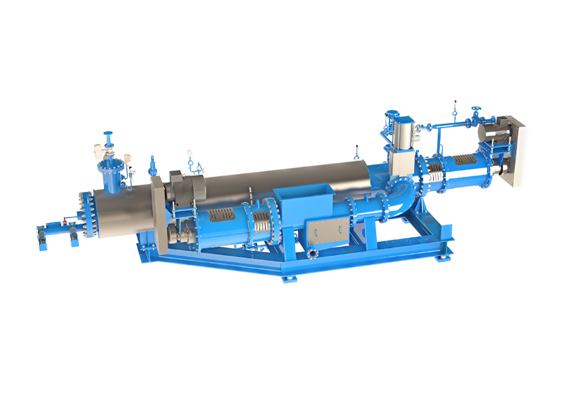

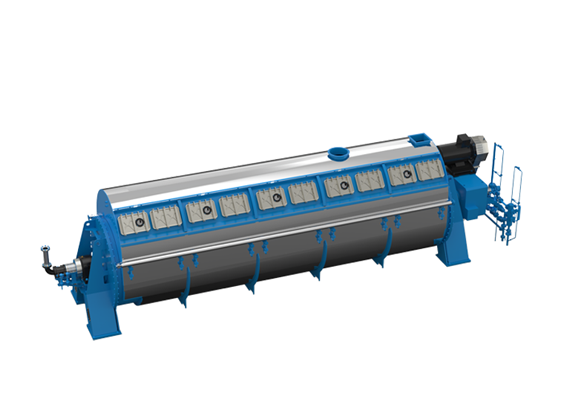

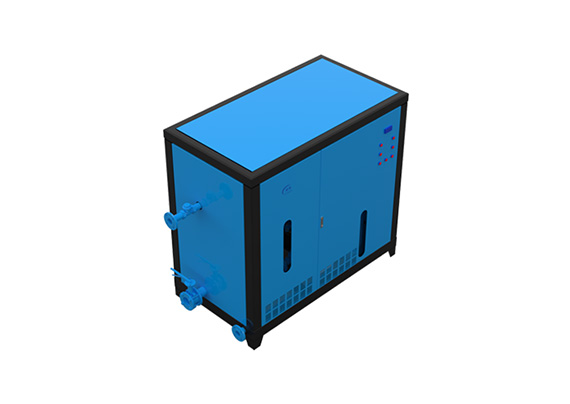

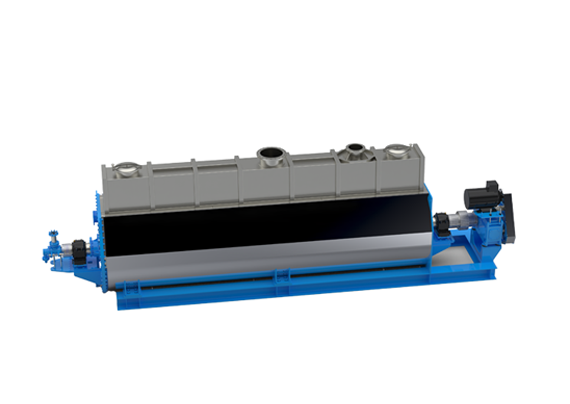

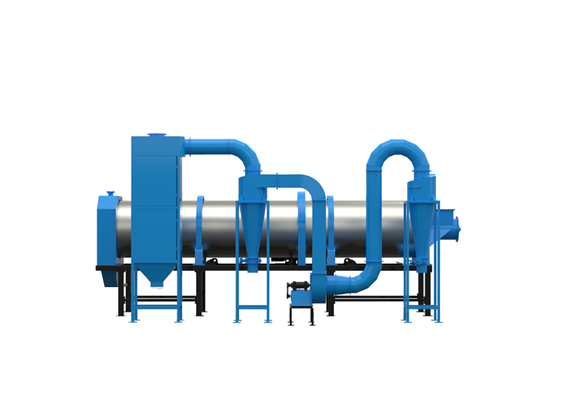

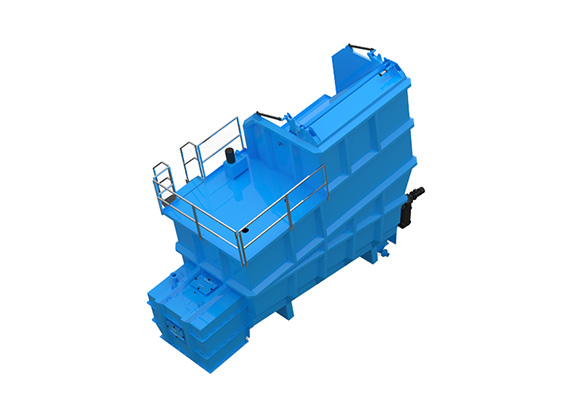

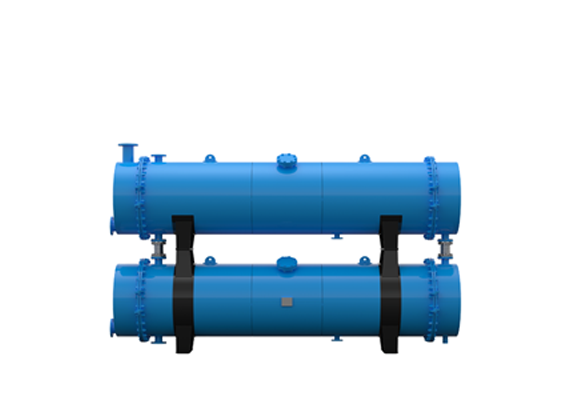

Feather meal processing machinery refers to specialized equipment designed to process poultry feathers (such as chicken, duck, or goose feathers) into feather meal. Feather meal is a high-protein feed additive or organic fertilizer raw material. Through high-temperature and high-pressure hydrolysis, the machinery breaks down the keratin in feathers, making it more digestible and absorbable.

How Does a Feather Meal Production Line Work?

Feather meal processing equipment utilizes high-temperature and high-pressure hydrolysis to break down the keratin structure of feathers, combined with drying and grinding technology to transform waste feathers into high-value products. The key lies in precise control of hydrolysis parameters (temperature, pressure, time) and adherence to hygiene and safety standards, ensuring both resource recycling and compliance with feed or fertilizer quality requirements.

Workflow Overview:

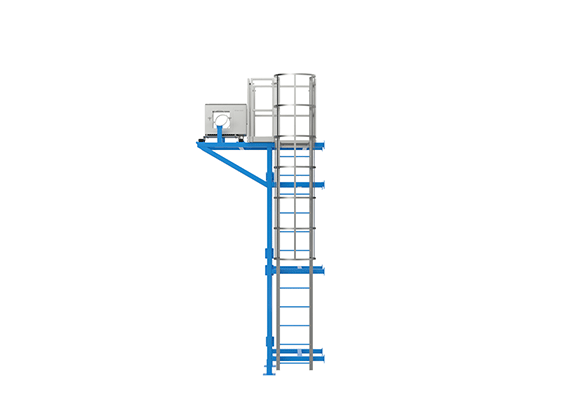

Raw material (feathers) → Pre-treatment (cleaning, sterilization) → Hydrolysis (high-temperature & high-pressure keratin breakdown) → Drying → Grinding → Quality inspection & packaging

Applications of Feather Meal:

As a high-protein resource, feather meal has diverse applications across multiple industries, primarily in feed production, organic agriculture, environmental protection, and emerging biomaterials. Its core value lies in resource recycling and cost efficiency. With technological advancements, it may expand into pharmaceuticals and high-end cosmetics, becoming a model for agricultural and industrial synergy.

– Feed Industry: Replaces fish meal and soybean meal, reducing costs in aquaculture and poultry feed (protein content: 80%-85%).

– Organic Agriculture: Acts as a slow-release nitrogen fertilizer (12%-15% nitrogen content), improving soil structure.

– Environmental Protection: Reduces landfill pollution and adsorbs heavy metals from wastewater (removal rate: 70%-90%).

– Emerging Fields: Biomaterials (biodegradable plastics), cosmetics (keratin-based hair care), and bioenergy (biogas production).

FAQ

What is a Feather Rendering Plant?

A feather rendering plant is a specialized facility that processes poultry feathers (e.g., chicken, duck, or goose feathers) into high-protein feed ingredients (feather meal) or other high-value products (e.g., organic fertilizer, biomaterials) through high-temperature and high-pressure hydrolysis, drying, and grinding. Its core value lies in transforming waste into valuable resources, enabling the circular utilization of agricultural byproducts.

How Are Your Equipment Transported and Installed?

Our large-scale equipment can be transported via sea or land, while smaller equipment can be shipped by air. We provide customized installation services for equipment and production lines, offering tailored solutions based on customer needs. Our professional technical team will be dispatched to the site to guide installation, commissioning, and production start-up, with customers only covering travel and labor costs. Alternatively, we offer free remote video-guided installation services, providing real-time support for setup, operational training, and troubleshooting to ensure rapid equipment deployment.

Does Your Equipment Come with a Warranty?

Our manufactured equipment comes with a one-year warranty.

The following scenarios are not covered under warranty:

– Damage caused by improper operation, unauthorized modifications, or intentional misuse;

– Failures resulting from force majeure (e.g., earthquakes, floods) or non-standard operating conditions (e.g., overloading).