Best Sunrise Systems Of Fish Meal Plant Line

Best Sunrise Systems Of Fish Meal Plant Line

Ⅰ. Fish Meal Plant Line Raw Materials

Fish meal is a by-product of the fishmeal industry. The raw materials are fish, shellfish, and crustaceans, which are processed by cutting, flaking, and drying or pressing.

The main raw material used in the production of fish meal plant lines is fish. In addition to the whole body of fish, heads, tails, and bones are also used as raw materials for producing fish meal plant lines. The fishmeal production process includes dewatering, flaking, drying, and pressing.

Ⅱ. Fish Meal Plant Line Cooking system

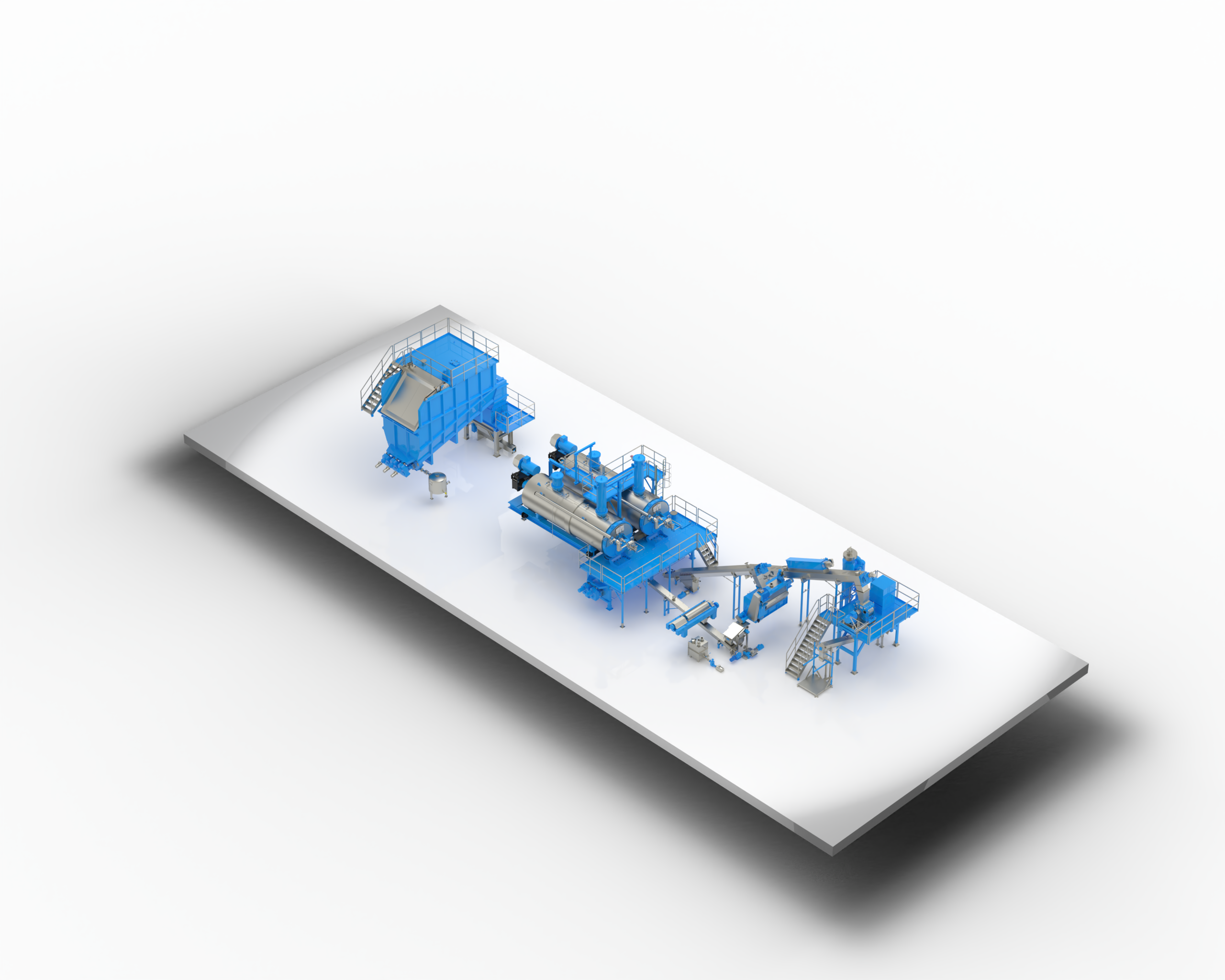

Fish meal plants are an essential part of the rendering process, as they convert the raw material into a finished product that is used in a variety of industries, including animal feed and fertilizer.

The fish processing process is to put the fish into the fish cooking machine for high-temperature and high-pressure cooking, and then enter the double-screw press for oil pressing. The pressed powder enters the disc dryer for high-temperature drying, and then cools and breaks the package. The pressed oil is separated and centrifuged to produce finished fish oil, which is then packaged.

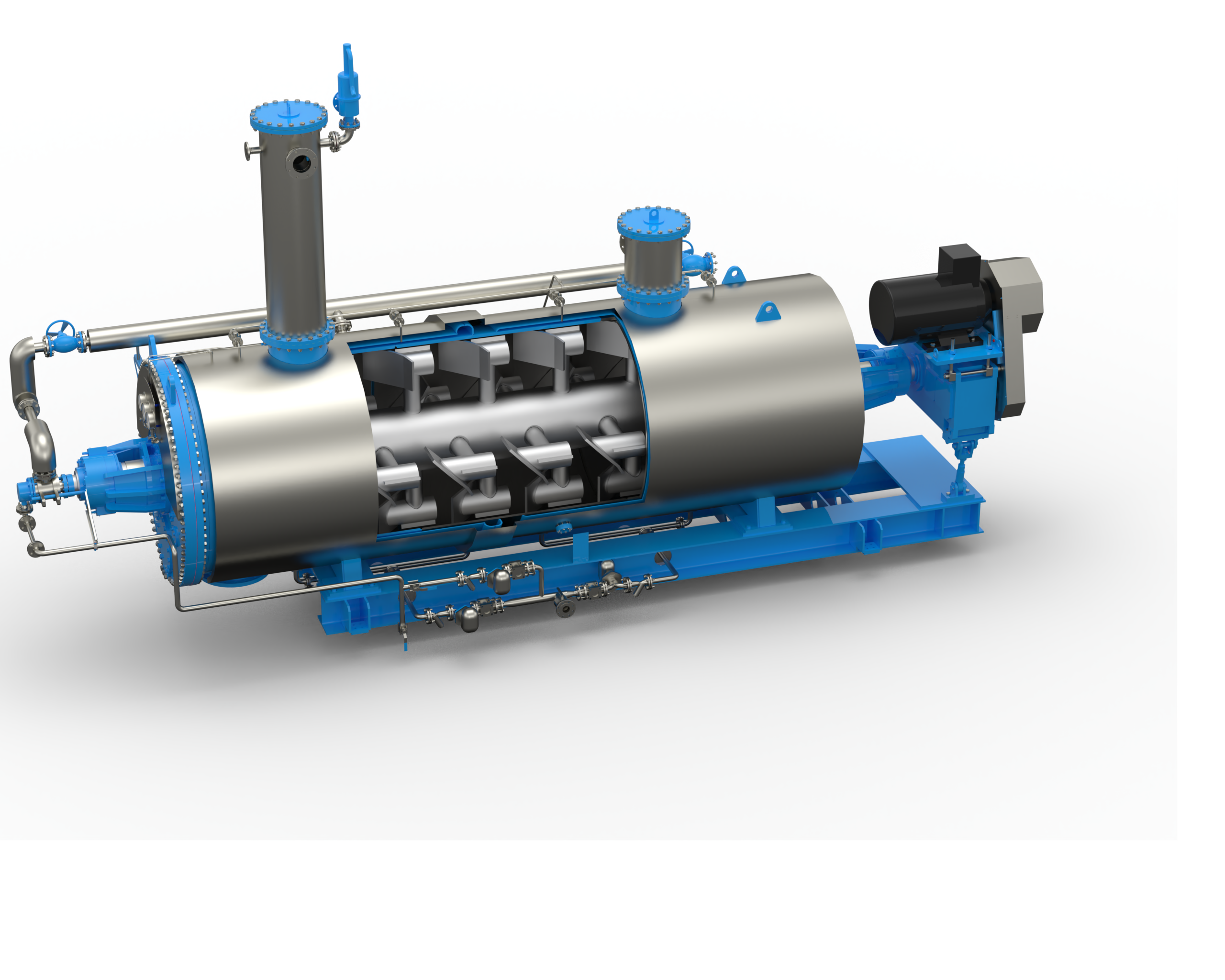

Sunrise Fish Cooker

Sunrise Fish Cookers are used for cooking fish and similar offal. The equipment consists of a stator base and a helical rotor. The stator base is equipped with a steam heating sleeve; the spiral scraper rotates continuously and is indirectly heated by steam. The steam casing is divided into different zones, and the steam header is used to achieve uniform distribution of steam.

The casing condensate is discharged through the condensate main pipe. The stator seat is equipped with a hinged door with a weight on it for easy inspection and cleaning. Each end plate is fitted with a stuffing box. Both ends of the rotor are supported by roller bearings. Both steam entry and condensate discharge are through the end shaft.

Ⅲ. Fish Meal Plant Line Oil pressing system

The main components of fishmeal are proteins, fats, and minerals. The composition of different types of fish varies greatly. In order to produce high-quality products, it is necessary to remove as much water as possible from the raw materials before pressing them. Furthermore, this process will also increase the yield rate of the pressed meal.

The fish meal processing line includes two kinds: wet system and dry system. The former uses water or steam to remove moisture from raw materials, while the latter uses air or vacuum to dehydrate raw materials before pressing them by extruder or screw press machine.

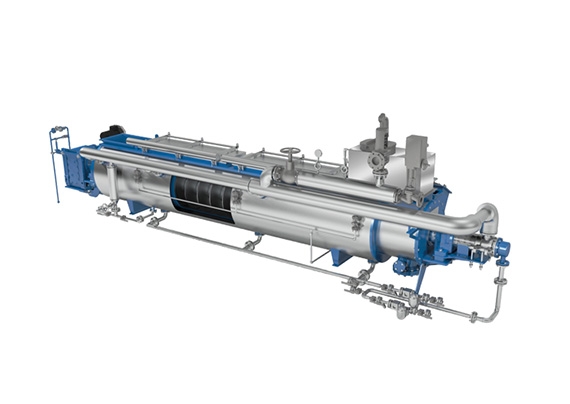

Sunrise Twin Screw Press

Sunrise Twin Screw Press is used in wet waste processing processes to extract liquid from cooked fish or meat. The twin-screw press ensures efficient mechanical dewatering, reducing the oil/fat content, which in turn improves the process and increases the potential for energy savings.

A twin screw press is a machine used in the animal rendering industry. It is used to extract oils from animal parts and bones. The extraction of oil from animal parts and bones has been an industry standard for decades and has led to the creation of modern-day pet food.

Ⅳ. Fish Meal Plant Line Drying System

Fish Meal Plant Line Drying is one of the most important steps in the fish meal processing process. As you may know, fish meal is an animal by-product that is used as a source of protein in animal feeds. If you have ever wondered what goes on in a rendering plant, then this article will help you understand more about it.

Fish Meal Plant Line Drying allows you to dry the fish meal so that it can be stored until needed. If you are looking to operate your own rendering plant or if you want to expand your current operation, this process is essential to making sure that your products are ready for distribution and consumption.

Sunrise Disc Dryer

The Sunrise Disc Dryer uses indirect steam heating for continuous cooking or drying of animal by-products or fish. The dry material needs to be fed from one end of the dryer. After the water has evaporated, the material is sent to the other end, where it is discharged through a variable-speed screw conveyor.

The rotor has a central tube to which a large number of vertically arranged parallel double-walled disks are welded. In this design, the heating surface is very concentrated, which can realize the special spindle with the maximum evaporation capacity in a compact design, ensuring efficient and uniform hydrolysis.

Ⅴ. Fish Meal Plant Line Milling System

The Fish Meal Plant Line Milling is a process of converting fish into valuable animal feed products. The main ingredient is raw fish, which is about 70 percent water, expensive to transport, and perishable, so it must be processed as quickly as possible. During processing, fish by-products undergo a series of processes such as cooking, pressing, and drying. The low oil and moisture content in fishmeal ensures a long storage time. A perfect source of highly digestible protein, essential vitamins, and minerals.

The quality of oils and proteins depends on the raw materials used, processing methods and equipment applied. Treatment is usually carried out on an industrial scale. It relies on drying and separating bones and proteins from fat. The main products from fish by-product plants are fishmeal and fish oil.

The Benefits Of Using a Fish Meal Plant Line Milling Include:

• It can be used to produce high-quality fish meals.

• It requires only minimal labor.

• It is easy to operate.

• It has a low operating cost.

Sunrise Milling Plant

A Sunrise Milling Plant is an automatic system, which adopts the DCS automatic control system. The system has a strong self-diagnosis function and can self-diagnose various functional states of various hardware devices such as various cards, controllers, and buses in the system. The diagnostic results can be displayed on the corresponding parts of the system and the operator station and give corresponding alarms.

The biggest feature of DCS in control is that it can realize diversified control strategies to meet the needs of different situations by relying on the flexible configuration of various control and calculation modules. The DCS control system generally adopts a dual redundancy design. The CPU, power supply, and network are all dual. Once the working module fails, it can automatically switch to the standby module without disturbance to improve reliability.

Ⅵ. Fish Meal Plant Line Storage and delivery system

Fish plant line storage and delivery system are very important for the whole fish meal line. Here are some Sunrise storage and delivery machines:

Sunrise Material Bin

With the need for an efficient and effective storage solution, Sunrise Material Bin was chosen as a cost-effective solution. The material bin is made from high-quality steel with a galvanized finish that prevents corrosion. It has a large capacity of 45 cubic meter and its transport weight has 18000 kg.

Sunrise Screw Conveyor

The Screw Conveyor is the heart of a rendering plant. It is used to transport the slurry to the cooker. The cooker receives raw material from the screw conveyor, cooks it, and discharges the cooked product. The screw conveyor consists of a large number of helical flights or steps that are arranged in a spiral shape.

Each flight has a horizontal step or flute between flights, which moves in an opposite direction to the flight above and below it. The flights are connected to each other by vertical shafts that run through their centers. These shafts are also called worms or screws because they resemble screws in appearance.

Advantages Of Sunrise Screw Conveyor:

1. The airtightness of the equipment is good, there will be no leakage of feathers, and the site environment is clean and tidy.

2. The spiral blade is thickened and wear-resistant and the bottom of the blade are equipped with a wear-resistant lining; the service life of the equipment is long.

3. The maintenance cost of the equipment is low, only the bearings need to be filled with oil regularly.

Conclusion

Fish meal plant line is unique in its own way because they have an extensive process that requires many different types of equipment and machinery that must work in unison with each other in order to produce high-quality products at affordable prices.

If any part of this process breaks down or malfunctions, then the entire operation will come to a halt until repairs are made or new parts are installed into place so they can resume production again.

Sunrise is a professional manufacturer of fish meal machines, its products are Water-Killing Systems, Fish Meal Extrin Machines, Fish Meal Production Lines Solutions, etc. Therefore, if you have plans to set up your own fish meal plant line, welcome to visit the Sunrise website.