Home >

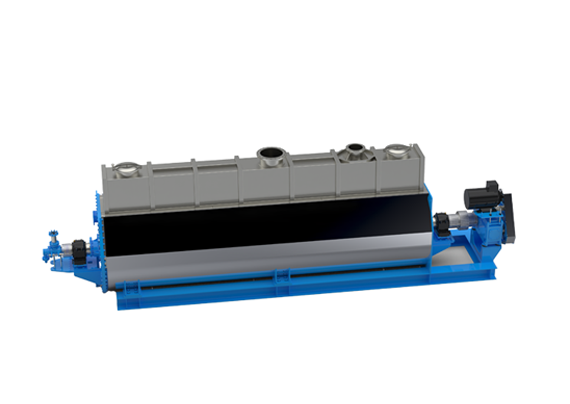

Continuous Rendering Process of Animal Fat (Disc Dryer)

The main purpose of animal fat rendering is to extract pure and high-quality oil from animal fats.

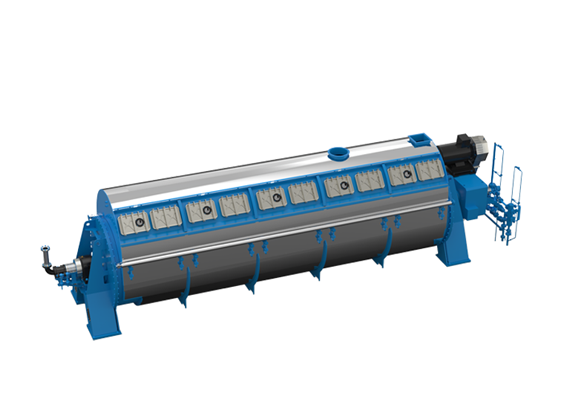

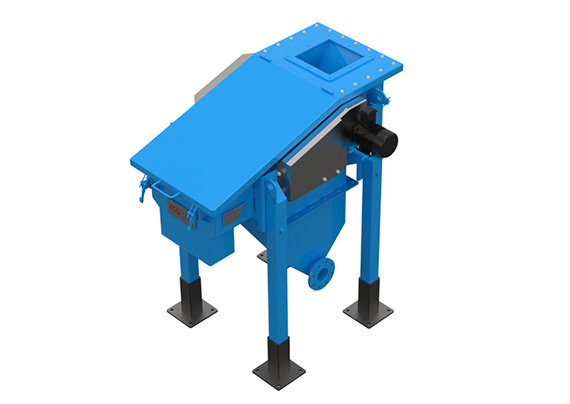

The following is a general overview of the continuous dry rendering production process of animal fat by Sunrise. Steam is used as the heating medium, and a preheating machine and a disc dryer are used for continuous oil refining. Materials are fed in and discharged out simultaneously for continuous production. The specific steps may vary depending on the type of fat, production scale, and the requirements of the manufacturer.

I. Raw Material Preparation and Pretreatment

1. Raw material selection: Select high-quality animal fats (such as those from chickens, ducks, cattle, sheep, pigs, etc.), fresh-frozen materials, and frozen lard as raw materials, ensuring that the raw materials are fresh, odorless, and free from pollution.

2. Crushing: Conduct coarse and fine crushing of the fresh-frozen materials and frozen lard blocks. Make the particles more uniform to increase the surface area of the raw materials and improve the rendering speed and oil yield. This step is usually completed by conveying the raw materials to the crusher through a chain plate conveyor.

II. Foreign Matter Detection

1. Conduct metal detection (by machine) on the crushed materials and plastic/plasticizer detection (by manual inspection), and remove foreign matters.

III. Rendering, Dewatering and Deodorizing

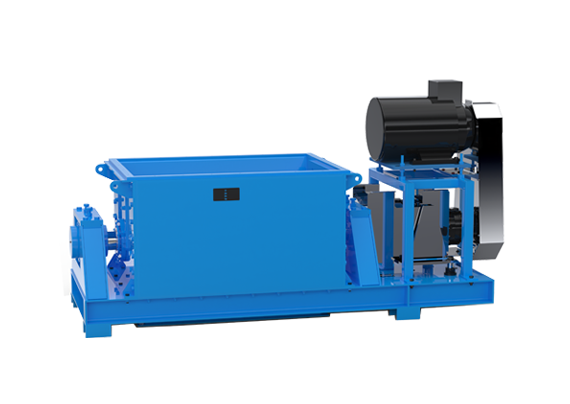

1. Continuous Rendering: The preheated raw materials will be heated and rendered in a disc dryer. There are scrapers inside the disc dryer, which features a large heat exchange area. By returning the oil through the equipment and adding base oil, it ensures that the materials are evenly heated, do not stick to the equipment, and effectively prevents the raw materials from being charred.

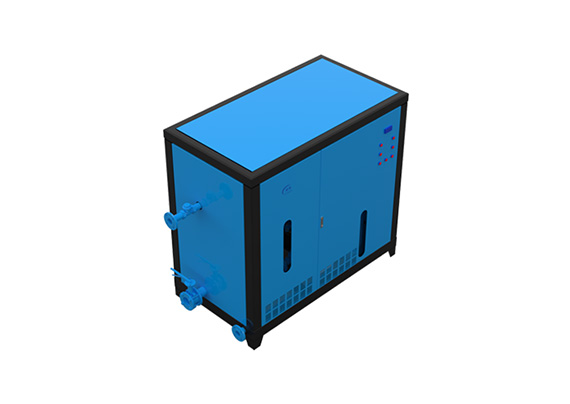

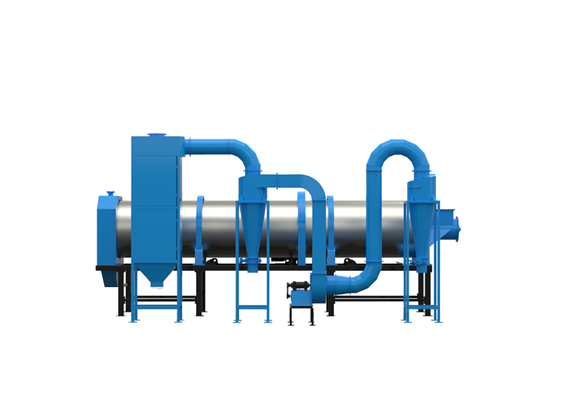

2.Dewatering and Deodorizing: Under negative pressure, the raw materials are gradually rendered into fat, and at the same time, water and odor molecules begin to volatilize. In a vacuum state, the water vapor and odor molecules generated during the rendering process of the raw materials will be quickly separated from the fat and flow into the condenser along the vacuum pipeline. The evaporated water vapor is condensed and discharged into the oil separator. The remaining non-condensable gas enters the waste gas treatment equipment, where the water and odor molecules are removed to improve the purity and quality of the fat.

IV. Oil Residue Separation

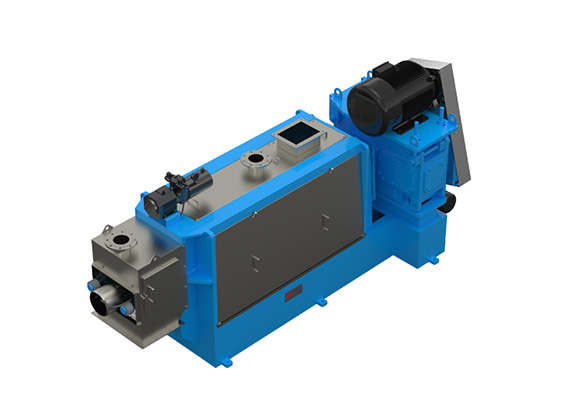

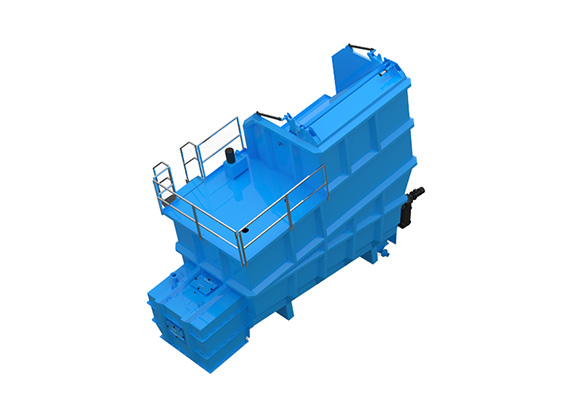

1. Oil-residue separation: The mixture of oil and residue after refining enters the oil-residue separator for rough separation.

The oil residues larger than a certain size enter the buffer bin through the oil residue scraper and then enter the oil press for physical pressing. According to the processing equipment and the grades of raw materials, the pressed animal fat is classified into food grade (used in the food industry) and feed grade (used in animal husbandry). The pressed oil cakes can be used as additives for animal feed.

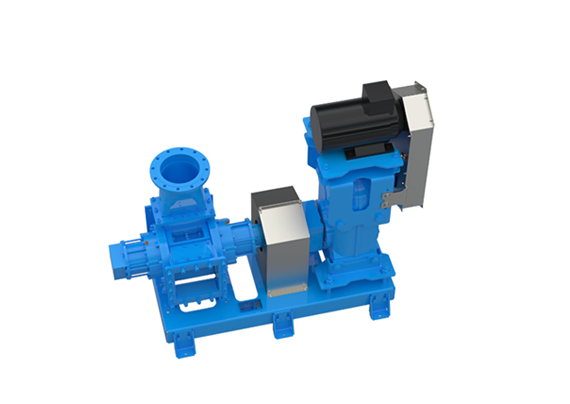

2. Decanter: The mixture of fine oil residues and crude oil will be pumped into the decanter for fine separation to remove fine particles, so as to obtain the refined oil.

V. Refining and Filling

1. Refining: Depending on the specific type of fat and quality requirements, a refining process may be carried out at the later stage of animal fat rendering. This process includes steps such as degumming, deacidification, decolorization, and deodorization, which aim to further remove impurities, unpleasant odors, fatty acids, etc. from the fat, thereby improving the quality and stability of the oil product.

2. Filling: Generally, sealed containers are used for packaging to ensure the stable quality of the fat during storage and transportation.